This is a follow up on a discussion on this post:

Dust-collection-of-my-shapeoko-4-pro-xl

I had a sled for my table saw since many years and did not used it very much because of a few limitations:

1- I could not use my Shark Guard dust collection with it, so a lot of dust trowed at me.

My nose and sinus have lots of problem with dust and I don’t want to work with a mask continously.

2- If I would use a dado blade, goodbye to the zero insert property, same thing if I use a narrower kerf blade.

3- If I want to use the blade at a tilt angle, cannot go back to the zero insert mode neither.

So I search the web and find a lot of ideas. The ideas that I took from my research is the adjustable kerf and the 45 degrees angle for cutting frames found on a few designs in my research. This guy’s video present what you can do with this kind of sled and how to build one:

[Flagship Table Saw Sled! Crosscut, Miter, Bevel, Dado, Picture Frames & More!

He has done a very good and simple design for people having mainly a table saw and a router. He sells kits, or drawings only or like he suggests in his video, make one yourself using his videos which I have done.

Since I have a CNC, I have designed and built it differently and added to it the dust collection which is the main feature I wanted and could not find any good idea in my research.

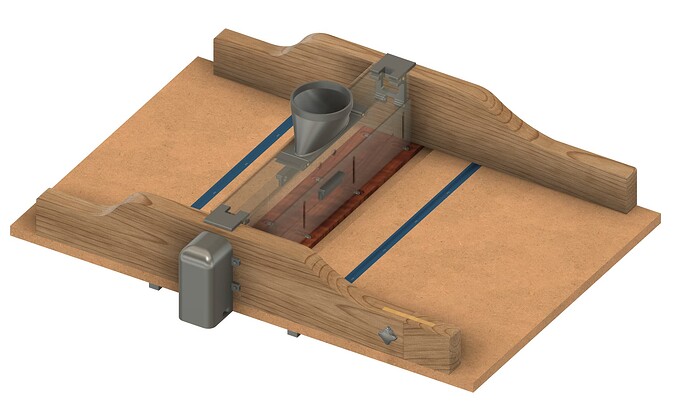

Here are some images from Fusion 360 of my design:

There are a few screws, magnets and small plastic prints spacers still missing in my Fusion drawing.

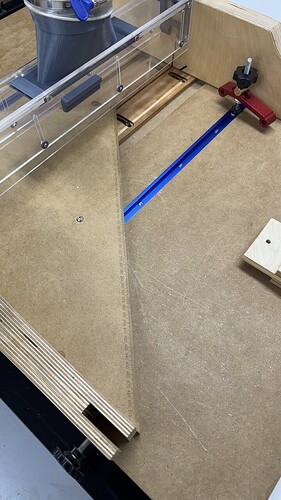

The sled is build using a 3/4" MDF sheet and recuperating my previous sled fences. I have used some hard wood for the adjustable kerf parts. All the slots, pockets, holes were CNC done and also some pockets on the bottom side to remove material of the MDF to reduce weight.

Now for the piece of resistance, the dust collection:

My inspiration is from my Shark Guard made by a small US company who is designing and selling guards with dust recuperation for many kind of table saw. I have it since many years and like it very much:

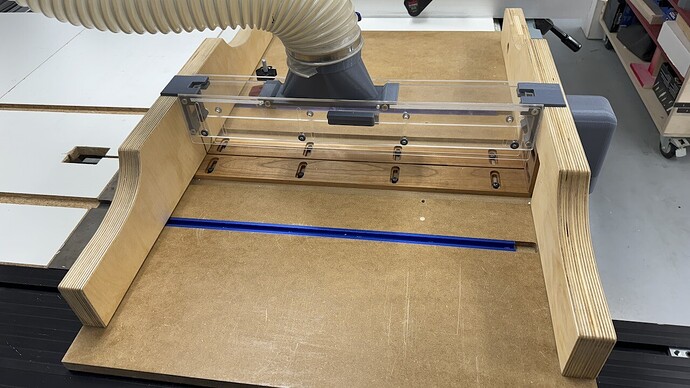

My dust collection is built using acrylic sheets (1/4" for the top parts and 0.08" thickness for the lower sliding sides) and 3D prints part using PETG material (all the grey parts). The acrylic sheets were cut on the table saw but the precise slots and holes were CNC done. You can slide up and down the lower parts sides and they stay up by some magnets.

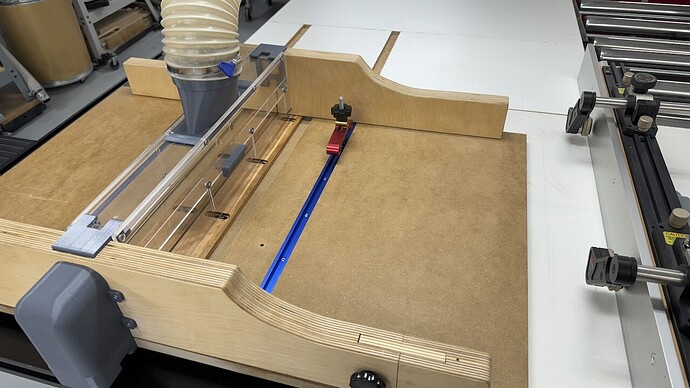

Here are some photos:

The dust system is hold down in place with magnets and can be easily move away.

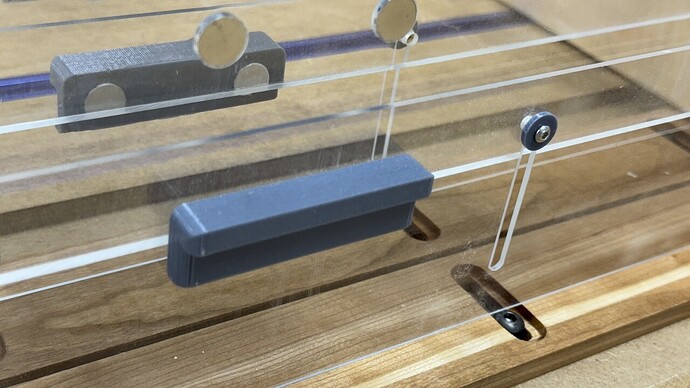

The handles magnets holders.

Here is a closeup of the mounting details.

Here is a photo with the framing jig installed.

I am very satisfied with the results but I must say that I have a powerful ClearView cyclone with 6 inch ducting which is split with a Y to 5" for the table saw and 4" for my sled top dust collector.

I hope this post will inspire some of you who are interested in such a system, you may improve on it. If you have some questions or want more details I will be happy to try to help you. Discussion is open.