Hi all,

Has anyone had any luck holding half round shapes securely for machining. Looking for ideas for a jig or clamping method.

I would machine a negative, line it w/ foam, and clamp it in that — probably centered along one of the T-tracks to get a little more depth.

Depending on what you are cutting out of it, I would consider screwing it down to a negative of it from underneath and then clamping the negative down to the table. you would then have access to the whole top of the stock.

Is any part of the top surface available for clamping, or do you need access to the entire top surface?

Can you dedicate any part of the top surface at each end to clamping, and cut those areas away later?

Can you screw anything into the ends, or will that be visible in the final product?

I’ve always clamped round parts into a " V " on a fixture that gets bolted/clamped to the table. You can use a horizontal piece to get it aligned in the V-fixture, and then hold it in place with traditional clamps to the fixture.

I’m not sure how much of the tree bark you will mark up with this method, but it doesn’t take much pressure to secure the piece into a " V ".

Wow, between the four of you guys you showed me the obvious solution.

I’ll cut my stock a bit longer than needed and drill a hole at each end down through it perpendicular to the flat side, along the center line. Then make a negative saddle so to speak and set both over the t track in such a way that I can use long bolts and nuts in the t track to hold the stock down in the saddle. When the carving is done I’ll just shorten both ends to get rid of the mounting holes.

I finally got back to this and tried a slightly different approach.

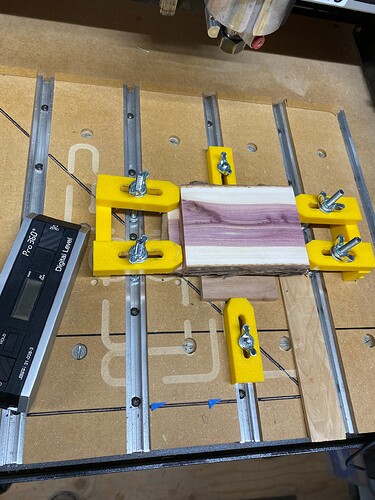

Leaving the stock a bit long I was able to cut a ledge on both ends for work holding. Using the four clamps, a wedge and a digital level I was able to square the stock to the spoil board.

Ed,

The steps on the ends of the stock are a great idea!

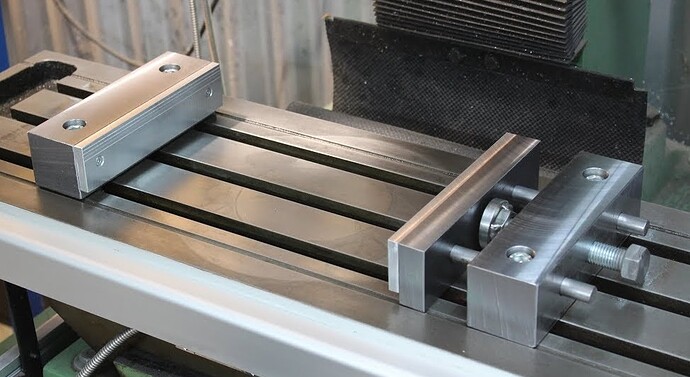

You could make a two-part vise out of metal or wood and clamp in the direction of the grain. Sacrificial wood jaws would allow you to machine all the way to the ends of your stock without worrying about machining into metal vise or jaws.

David

Thank-you David, that’s another great idea.

This topic was automatically closed after 30 days. New replies are no longer allowed.