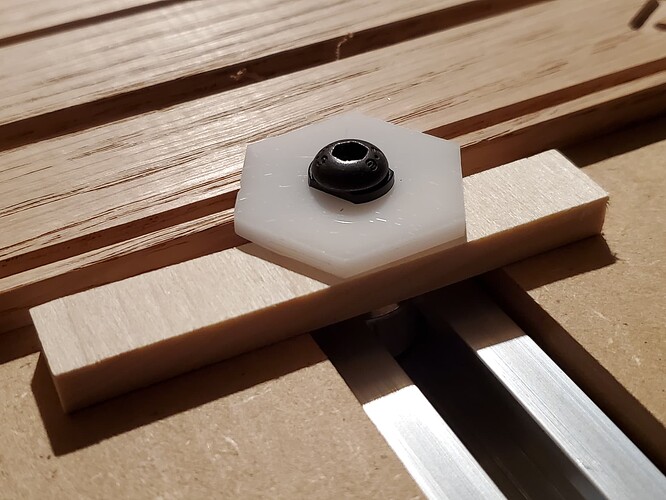

It’s been a while since we had a discussion on this — naturally we hope Santa is bringing everyone Crush-It clamps and so forth, but there are times when one wants something a little lower in profile — for such situations I’ll often use plastic washers (I usually cut them from acrylic):

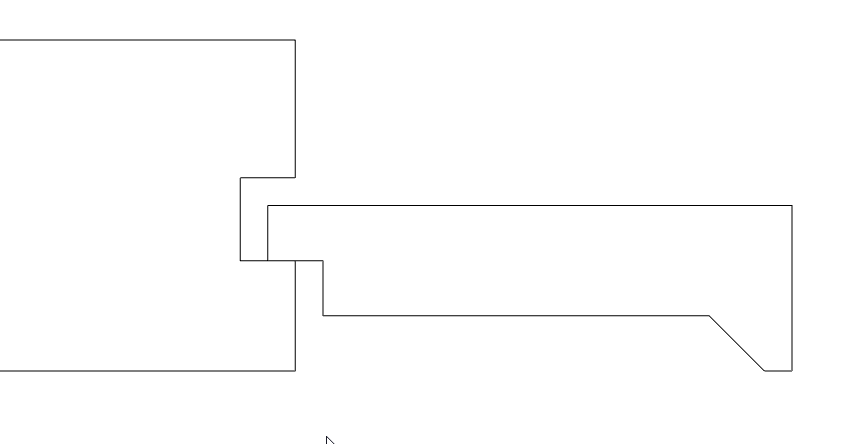

An option I’ve used a few times when working on a thicker piece, I don’t want to drill any holes, and I need to surface the whole workpiece is to table saw some grooves in the side & use the clamps in the slots.

A long time ago I got some of the OOPS clamps. I have never really used them but recently started using them on some plaques I am cutting. Typically I use painters tape and super glue or my cam clamps but these plaques are 20" X 14.5" and that would take a lot of painters tape and super glue and I have 15 of them to make. So I dug out my OOPs clamps and used them to hold them down.

The advantage of painters tape and super glue is I dont have to remove the tabs after the project is cut.

Another long time ago I bought some HDPE 2" round 5/8" round blanks that you can drill a hole in and use like @WillAdams is using his smaller profile clamps. The obvious disadvantage of the taller pucks is they are taller and easier to get hit by the spindle. Since they are HDPE likely would not cause any spindle issues other than maybe losing steps if you hit them hard enough and that can be fixed by re-homing.

We have a lot of mad scientists working in their garages making some creative ways of holding down things.

This topic was automatically closed after 30 days. New replies are no longer allowed.