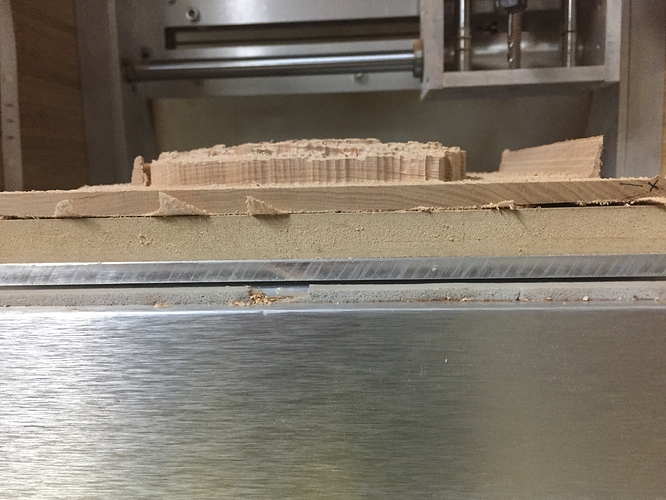

Hi, I can try to send the .nc file once im back home. I used #101, with the default 101 setting in Meshcam. The only thing change i made was disabling the setting for Angle Limit 50 degree (or what it is called), so that the NOMAD actually smoothes it later, otherwise it stays with the ridges.The stock was a flat piece of wood, it cut it fine just once it went into the finishing XY it started being off. Anytime that the NOMAD is off (and i had it several times now, especially for longer carvings), its in the finishing pass at the end, which is nice to see since it was off at the point when it started on its x finishing pass. It almost looks like that stepping artifact because that ridge is also not straight but shaped like a wedge. Jorge wanted to send me a new board once the shippment gets in to them too.

As in my reply to the other post, seeing your meshCAM settings will also be helpful, but I’m also thinking there could be board shenanigans contributing.

It looks like your wood may have cupped a bit during cutting? That could also cause the initial engagement of the tool to snag, and per my comment above, if it’s hitting a full tool-engagement on what it’s expecting to be a finish pass, that could cause it to bog down.

Hi,

i will try to get the settings later, but i always use defaults and just uncheck the Angle limit check-box to get it smoothed.

Rest is default. The cutter is the correct one, i have checked them all after getting a few mislabeled ones, so i can rule that out too

The bending off the wood is caused by me trying to get it off the plate once i stopped the job, but then decided to leave it on there for the pictures.

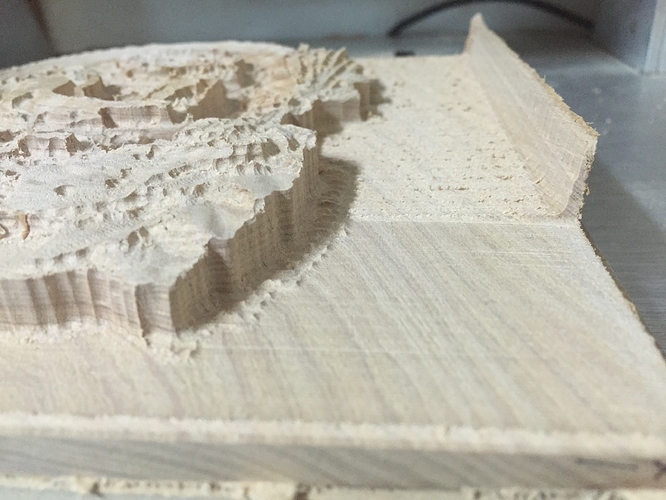

Same thing again, a longer carving, but not very deep.

Also, its fairly easy to see on this one that the X axis is wandering off towards the longer the job runs.

.

It looks like a double-vision on the bottom of the circles if you look closely.

Also, there was a ridge on one side of the carving that was getting wider towards the bottom, although it should have been a straight wall (like in my first post above). The cut is not deeper at any point than the flute itself, or flute + neck so the tool never should have hit any sidewall.

@Jorge : do you think the new board will fix that issue?

Dooing the recommended modification, fixed the same issue on my machine.

Changing the board fixed it for me too. I just finished carving the same piece from the same file and same wood, and no issues this time, very happy