![]()

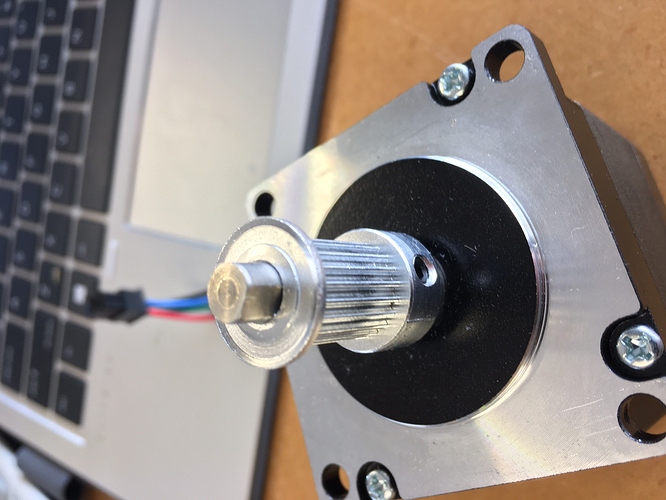

The set screws definitely are not aligned…

I am slightly worried that I might damage something getting it off and around though - its very tight…

any tips for a smooth, no damage extraction…?

Support have not said too much at the moment, could be because of NY shutdown?

Kind regards,