My X-travel on my Shapeoko XXL is extending too far either to the xy zero location. It travels 1.1 inches too far. It also is traveling too far back to the right to start a cut.

Calibrate for belt stretch?

Or check the machine mechanically?

The belt is appropriately tight.

1.1 inches is a lot.

but eh… can you be specific, does it think your machine is wider than it is ?

Also do you have a suckit + HDZ ?

I am slightly unclear of what exactly you mean… could you maybe do a diagram or something?

is it going wrong at jogging, or while cutting, and at what distance (size of work) if you’re cutting?

It is going wrong at jogging from the home location to the zero set usually in the lower left corner of the workspace.

I dont know if the machine thinks its wider than it is since it doesnt always do it. It usually happens when I have aborted a program and it went to the home location. When I bring it back to the previous xy position, it goes too far.

Why do you usually abort the program? Could it be that you’ve crashed the machine into something between homing and returning to home? In that case the issue could be lost steps.

Doesnt happen with my other Xl machine. Only this machine. I might stop the program because I am happy with the carving midway through the program

stopping is fine, and you should be back within say 0.1mm or so (homing switch accuracy) or less

so something else is up

I understand. That is my problem. It only seems to be on the x travel long distance. I just dont know enough to determine causes.

I had something kind-of similar. Towards the front of the machine (Y travel) it seemed to loose track of where it was, but towards the back it behaved perfectly. Turned out I had a damaged belt and it was losing steps when it found the weak place on the belt - spotted an ‘odd indentation’ in the belt, and found the belt was not far from separating at this point. Not sure why as some report many years of belt life.

I looked. Nothing there. Thank you for the idea though.

When this happens, what “Position” coordinate values does Carbide Motion show once it has reached the zero point 1.1inch to the left of where you wanted it to go ?

It says that its in the 0,0 position usually 0.236 above as i will also look at the z axis

This may be redundant but have you checked stepper motor set screws? Have you resent config? Seems like a lot of play for belt stretch but have you cut a couple of 6 inch squares and measured that the squares are 6 inches?

Mmh, then the machine thinks it did the right number of steps to go from home position to X0Y0.

Just to check my understanding, is what you observe the following ?

- zero somewhere in the front left part of the machine

- run a job there (I presume that it runs OK and cuts pieces to the desired dimensions when you do ?)

- pause and stop the job during the job: machines goes back to home position

- use CM quick button to return to X0Y0: machine returns ~1" left of where the zero was previously.

- no suspicious mechnical sound at any time throughout this sequence.

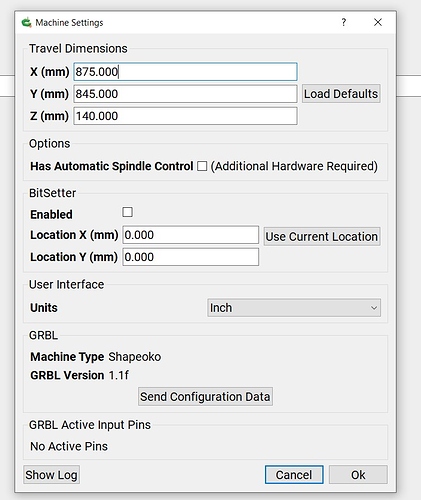

Can you check what value you have for $100? (in CM go to Settings, “Open Log Window”, then go to MDI tab and send $$, then check the log window it will have printed the $ values there)

The MDI tab is in the main CM window, along with Jog, Run, and Settings tabs

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.