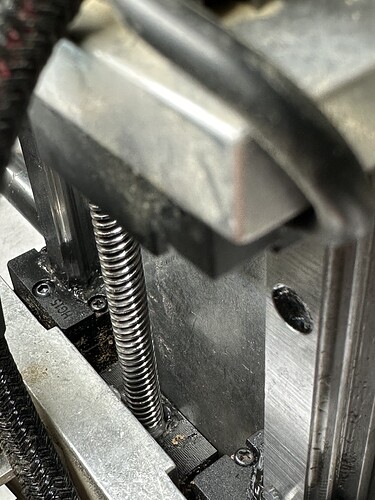

I’m debugging a strange issue, where specific X and Y positions seem to lock up the Z movement slightly, causing it to hold back perhaps 0.2 mm, before snapping into place. While doing that, I noticed that the black part on the Z-axis leadscrew is loose, and wiggles left and right. Should it? I’m guessing this is part of the anti-backlash nuts, and there doesn’t seem to be any screws at all in it ![]()

People have reported here on the forum that the backlash nut has come loose and caused problems. So I suspect if it is loose that would cause problems. The purpose of the backlash nut is to keep the slop down when the direction is changed. So if the backlash nut is loose it would not only prevent backlash but likely exaggerate backlash.

Talk to support at support@carbide3d.com to verify how to fix it if necessary.

EDIT - This is for the S3. The Nomad apparently has a bottom fixed nut.

The AB nut has two halves. The top half should NOT be loose, it should be fastened to the Z Carriage with 2 bolts.

The bottom half is ‘floating’. It will appear loose, but it will not rotate too much simply because it is too wide. This is normal.

If the top half of the AB nut is fastened to the Z carriage, but appears to be loose on the screw threads, then your nut is worn, and may need replacement. If so, contact support - the nut is not available in the store.

https://community.carbide3d.com/t/z-plus-leadscrew-nut-replacement-how-to-guide/53601/4

Huh, that’s weird. There’s definitely no bolts on the top part. The bottom part does seem to be bolted on, though. Are you certain that the floating bottom is the correct setup for the Nomad 3? If so this must be put together incorrectly.

Ah, a Nomad, this is new information. I see now that the category is Nomad, I didn’t check that.

The setup I described was for the S 3 with the Z Plus. So, if the Nomad used a fixed bottom half, swap upper and lower in my advice above for the Nomad.

Having the top half be the fixed half was never the right way of doing things, that was an engineering design mistake for the S 3.

Alright, that makes sense.

It leaves me somewhat stumped in terms of what’s going on, though. I don’t quite get it to add up to backlash, as I guess that should be consistent. This Z lockup and snap-into-place only happens after several consequtive small motions, or for specific places in the X Y dimensions. All of which makes very little sense to me. Still open to anti-backlash nut wear, or something beinng off with the linear bearings.

Edit: The bearings seem fine. I disassembled the carriage to get at the anti-backlash nut. The question now is whether this play is within reasonable limits? I mean the nut can be wiggled somewhat, but is it too bad? https://youtube.com/shorts/c_ksqcIyGY8?si=_Ge2z6ZfPPCPG8Rn

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.