I guess when it rains it pours. After struggling with USB disconnect problems, our Nomad has suddenly developed a lot of play in the Z axis. We often use Dowel pins drilled into the wasteboard as a quick two sided part fixture. We have had great luck with this until now when the dowels suddenly are loose. A quick look at the mill and we can see a bunch of movement back and forth between the bearings and rails on the Z axis. We’ve almost exclusively cut plastic on the mill with an occasional very light aluminum job. We haven’t had any hard crashes or anything else I would consider damaging, but all of a sudden we have parts no longer accurate and no good way to drill accurately. Has anyone else seen this issue? It’s put us in a real bind, we had a set of small plastic parts we needed Monday and now we have no way to make them.

See a video of the problem here

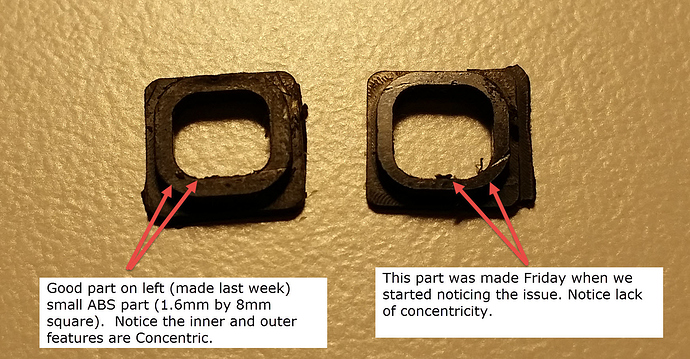

I’m also attaching a photo of what the impact is on our parts.