Need some help with an issue with z-axis. I updated software to I think 622 two weeks ago. I started a job that I did before update nothing changed in the file. First cut is advanced vcarve at .115 doc. I zero the z and started job. I zero at top of material. It starts cutting and it’s going prob 1/4” down to where the letters are fat and deep. I stop the job and go back and look at every thing again. Haven’t used machine since then. The other day I’m bout to make catch all tray and going down 1” for the bowl. Check everything zeros and all. Job starts and I’m looking and notice it’s still going deeper and deeper til it goes through the bottom. I stop it again. Check try again same thing with changing the doc to .75” is we it’s bout 1” down. I stop it. Today I’m looking and when I rapid position to 6mm it’s stops high than that. Should be close to .25” off material it’s higher. So I add machine from beginning in motion to see maybe something can be reset. It’s still higher than the 6mm but when you lower z to top of material it’s saying 0. So I go look for updates I see 635 I update it and same thing. I run test at .125” .100” and .01” and all of them are still deeper than the doc. .125 is about .25” after cut. Is anyone else having this problem or is there a simple solution to fix the z-axis in settings. I seen something online where someone said they had to fix line 102 or something for similar issue but didn’t explain how they did it. The top left circle is set at .125 and that’s more than that depth.

Thanks for your feedback.

Which machine do you have?

Which Z-axis?

Could you post your .c2d file and let us know step-by-step how you are securing your stock and setting zero relative to it and managing all tool changes?

I have shapeoko 4 pro xxl. I secure my work with double sided tape for over a year now. XY is always in same spot I just adjust the Z to the stock height. Once everything is set I jog machine away from the xyz settings and then double check with rapid position to xy and the 6mm z. I load the file check preview to make sure it looks like its supposed to cut. Start the job machine ask for the tool for first job I switch it out if need to then goes to bit setter and begins. Been doing this way for a while now with no issues until I updated Carbid motion. Today I noticed that when I do rapid z to 6mm it’s higher off stock than normal. I move the z down to 0 and it’s right at touching the wood at 0 setting. Once I start it’s going past the set DOC.

Sumaiyah.c2d (364 KB)

Could it be that you have a Z-Plus Z-axis but have configured for an HDZ?

I have it set at Z- Plus. Just measured and it stops at about 8mm above stock.

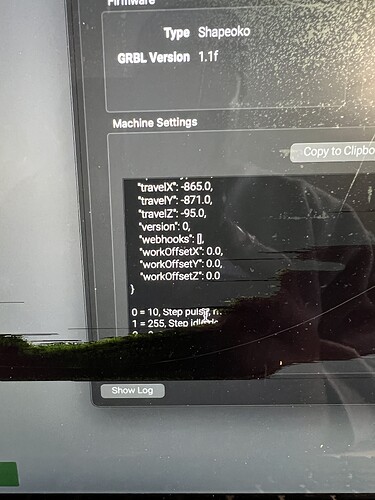

I found some settings you had posted in here years ago. My 102= 320 which is for hdz and I don’t have that installed. I have z plus which should be 200 and double checked that I chose z plus when adding machine. I have the hdz just waiting on spindle to install all at once. Is there a way to change the 102 value back to 200?!?

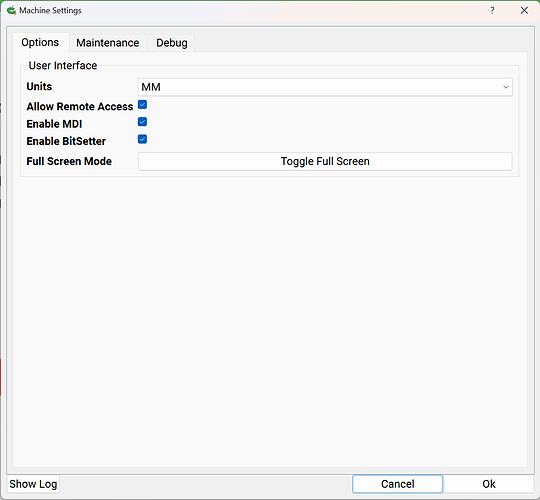

Enable the MDI, then go to it and send

$102=200

Where do i do that?!! Connect to cnc then all in settings? Thanks

Thanks!! I’m back!! When I install spindle and hdz I just got back and set up new machine right?!?

Yes, the Setup Wizard is the normal way to handle this.

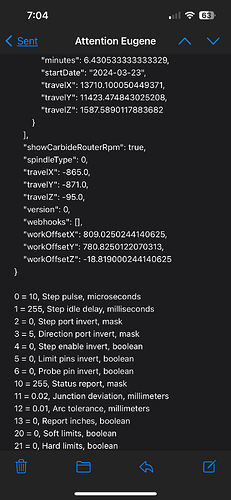

Thanks for the help last week again. New problem my X and Y position stays at 0 when machine is moving. If I jog it it won’t move back or to the right. Only thing that changes is vel and z. I have shut everything down and set up new machine. I went to the debug to compare what I emailed last week and noticed something different see attached pics.

Work offsets had value last week now shows 0 could thst be the issue?!?

Thanks Will.

WorkOffsets are based on what the home position is set to.

If the machine doesn’t move/home as normal that needs to be addressed — possible problems:

- belts not adjusted

- pulley set screw not secure

- motor wiring fault

- stepper driver failure

If you can’t find anything obvious to address, then you probably need a new controller, but that’s something to work out with the folks at support.

It will go home and initialize and move to bit setter but all 0 when traveling. Even when I set the bit setter it showed x and y 0. This not good cause I just got my vfd spindle few hrs ago. Thanks I’ll hit up support thanks again.!!!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.