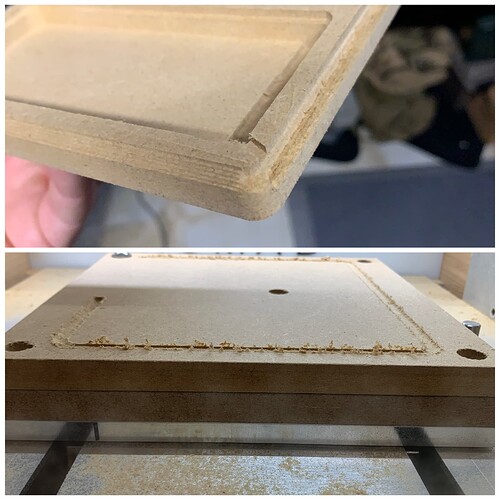

I ran my Nomad most of the weekend without issue but yesterday while trying to create a tool caddy, it failed. The depth of the cuts were way off and it drove the bit through a corner of the holder and took too much material off the side. (first pic). I then decided to try again. It cut the right side fine and when it retracted, I heard a loud popping noise and the spindle was in place bouncing up and down then it cut the left side super deep (second pic). The depth is almost 2mm difference. I did some testing and when it pops, carbide motion thinks it’s moving but it is not and it’ll plunge the bit deep into the stock.

What feeds/speeds and endmill were you using? Have you cut any aluminum recently? It sounds like your z axis got hung up on its retract, skipped a few steps then went to cut the other side thinking it was where your retract distace should be but it was 2mm lower give or take. All steppers on the carbide 3d machines are open loop so they do not report back to your sender where they are, they just follow orders from the controller on where to go. Might be worth while to give the rails a good maintenance session/ look over.

Feeds and speeds, I’m not exactly sure of off the top of my head and I’m traveling for work so I can’t verify til Friday but I’ve been using the default values from meshcam. I did cut a test piece of aluminum last week but have been cutting bamboo and mdf mostly. I probably have less than 10 hours on the machine and I keep it fairly clean.

I dont use meshcam but i would check your retract height for the file for the project. It sounds like it might be too much causing the lost steps discussed earlier.

Or maybe you can recall if prior to the popping noise was it retracting higher than normal projects?

I want to say the retraction was set to .5 inches. I’m not sure if that’s .5” above stock or above current cut. I’d assume it’d be above stock. The stock was just .5” MDF so nothing crazy. What CAM SW do you use?

Rails like to run pretty wet, I wasn’t applying enough lube. Cut my tool caddy with success.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.