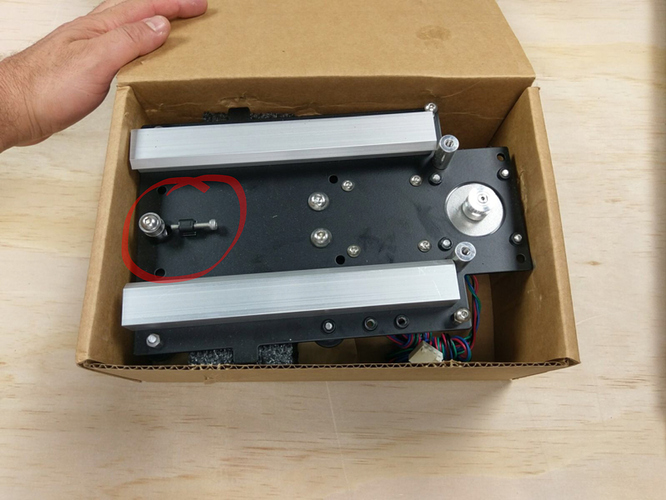

Ok, I’m having issues with the z axis. The drive belt is loose and that seems to be the cause of unstable z axis movement. So looking for a method of adjusting the tension but there is no take up adjuster on the backplate. Outside of opening the hole into more of a key way is there another method in use for this. Really don’t want to buy a new back plate with the adjuster as I’m hoping to get one of the new z axis units when they become available hopefully soon. If you look at the photo, the circled item is missing on mine

.Let us know about this at support@carbide3d.com and we’ll send you a Z-axis tension bolt.

If you’re making a run to a hardware store it’s an M4 SHCS ~25mm long.

However, if you have an older machine, then there is no M4 Z-axis belt tension screw — this was a modification in I believe summer 2016 — to tension the belts on older machines you use a sliding motor mount.

Best way to do this is to put the motor as low as possible and tighten everything up as much as possible, then get a luggage scale, loosen the motor slightly, pull up on the belts for ~18–20 pounds of force and secure one corner — repeat for each corner slightly increasing the tension.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.