My Z carriage belt has come off. Do I need to take the whole Z carriage apart to fix it.

Can someone give me some advice on how to fix it

Thank you

Verity

If things are mechanically sound on a new style belt tension system you should be able to loosen the M4 Z-axis belt tension screw and get sufficient slack to reinstall.

If you have difficulties send photos or e-mail support@carbide3d.com

Hi,

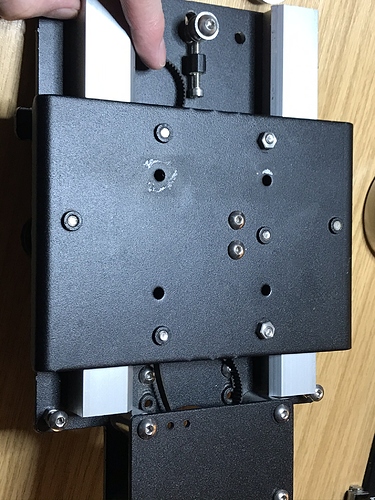

As I happen to have an unemployed standard Z sitting under my desk, here’s some pictures of the insides and what you may need to put back together.

It may help to remove the router from the bracket, depends how far off the belt has come.

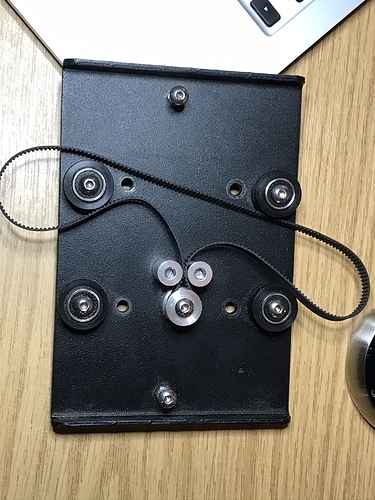

On the back of the plate that carries the router;

There’s the four black V wheels that let it ride up and down and the triplet of aluminium pulley and posts that act as the anchor for the belt, it’s meant to be looped through those so that the belt teeth are on the inside of the loop and engaged on the teech of the stationary pulley.

Hopefull the belt is still attached here and it’s just come off the stepper motor pulley at the top.

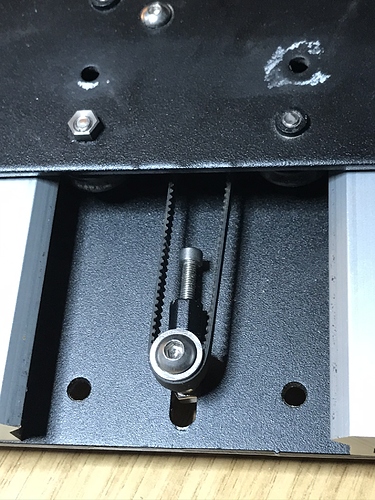

Here’s the belt tensioner Will mentions;

The bolt facing us carries the tensioner bearings and may need to be loosened a little. The bolt that is side on in this pic be turned anticlockwise to allow the tensioner to move up the plate, you can reach this behind the router carriage plate with the long arm of one of those hex keys that came with the machine.

With the bottom of the belt clear of the lower tensioner pulley to give some slack to work with, you’ll want to get it back over the stepper motor pulley at the top (those long hex keys are good for that too).

Once the belt is back over the stepper, persuade it back onto the tensioner at the bottom, it can help to roll the belt around this by pulling the router plate up and down.

Once it’s on, screw that tensioner screw back in until the belt is nice and tightly on the mechanism and doesn’t skip teeth on the stepper when you pull it up or down. Then tighten up the main bolt that the bearing is on, you may need to hold the nut on the backside with a spanner for this.

I’d suggest checking that all your bolts and V wheels are reasonably tight whilst you’re there, something was probably loose to let the belt jump off.

HTH

excellent thank you it worked

Verity

Thank you Will it worked

This topic was automatically closed after 30 days. New replies are no longer allowed.