This can be quite confusing and a PITA in Fusion and with Carbide Motion which doesn’t warn you that the machine will be instructed to move beyond limits by the GCode you loaded.

When using longer cutters or thicker workpieces it’s quite easy to end up running out of Z travel and listening for the thump and stepper grind is something I do on taller jobs.

The machining heights are explained a little here

https://help.autodesk.com/view/fusion360/ENU/?guid=GUID3EB12C22-C06B-4601-ABFE-7F1ECBABB9CE

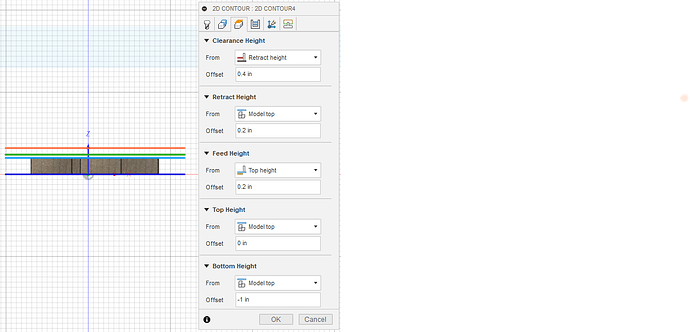

But, taking your screenshot as an example what you’ve got is everything set around Model Top, not sure if you’re zeroing on the top of the stock or down on the spoilboard, doesn’t make much odds to this issue.

Your toolpath Bottom Height is Model Top - 1" , not sure if that’s deliberate, but if your model is 1" thick, you could leave this as Model Bottom, generally only override these heights if you’ve got a good reason to. This setting can be useful to override if you want to limit how deep into a model the toolpath will cut, for example to keep a parallel or other finishing toolpath from dropping into cutouts or bores by selecting the model surface you’re finishing with the parallel and saying -0.001in

Your toolpath Top Height is the model top, that’s normal, the window between toolpath top and bottom height is the normal cutting space for Fusion, although depending on how you set up your stock you can cut down to top height in steps removing stock, see here for some more info

Your Feed Height is then set at 0.2" above the Model Top, that’s pretty normal, the feed height is where the machine should lift to for linking moves within toolpaths.

Your Retract Height is set to the same 0.2" above the Model Top, again pretty normal and sets clearance for rapid moves between cutting.

Note on Feed Height and Retract Height, if you have clamps or anything else sticking up above the model, you’ll need to either ensure that there’s no linking moves that go through the clamps (plastic or plywood clamps are good) or set these heights to above the clamp height above the workpiece.

The bit that may have caught you out is Clearance Height which is set to 0.4" above the Retract Height, thus 0.6" above the Model Top. This is the height at which the tool starts and finishes each operation, and for the rapids between toolpaths.

Given your model, you’ve got

- 1" of model

- plus 0.2" of feed / retract height

- plus 0.4" of clearance height

- giving 1.6" above model bottom that the Z will try to take the tool to at the start and end of each toolpath.

If you want to check this before a job you can zero out your tool, then try to manually jog Z up to the clearance height. If it won’t go then you don’t have room for the toolpath.

For example, assuming you have Z=0 at the model bottom then you’d zero out there with the tool, jog to Z=0 and then try to jog up to Z=1.6 inches. If you’re doing Z=0 at the top of the model then try to jog up to Z=0.6 inches.

HTH