I have the xxl. I have it programmed to cut .235 and it is cutting .375. All my programs are up to date as are my processors. I have clean the collect and re-zeroed and million times. i checked all connections on my wires. i am using the paper method and cutting pvc. i have the correct z pick on motion. please help

What is the toolpath you are cutting?

Is the tool pulling out?

How are you setting zero relative to the stock?

I did a little math. The HDZ gets 320 steps per MM and the Z-Plus gets 200 steps per MM. Are you sure you set the correct Z when running the machine setup.

320/200=1.6 .375/.235=1.59 (1.6 if your measurement was just a little bit off). So I would suggest you go back through the machine setup and make sure you picked the correct Z.

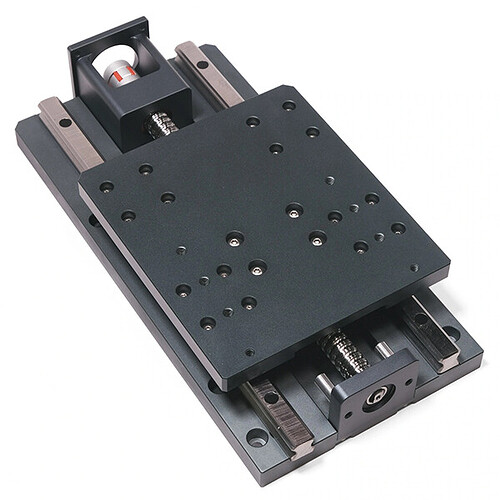

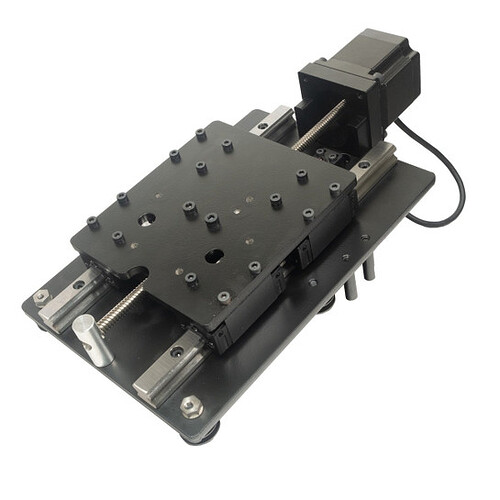

The HDZ has a large block at the bottom of the ball screw with a bearing. The Z-Plus has a stud with a hole in it and no bearing. The lead screw on the Z-Plus just goes through the hole without really touching it.

HDZ

Z-Plus

This topic was automatically closed after 30 days. New replies are no longer allowed.