My basic question deals with the 5 Pro saving the “zero” coordinates of a given “job”. I am aware that once you turn OFF the power to the machine, then you need to redefine the location of your stock. But what about for non-power OFF situations? I can accept that if something happens that may cause a stepper motor to skip a step, that the machine should be re-initialized and your stock’s position reset to the machine. But what about other situations?

NOTE: Per Will, the ZERO coordinates are maintained even through a Power-Off Situation.

Let me give a specific example followed by some questions that I am still confused on (1 month old user).

I have a job where I will be drilling 77 holes. There are (14) 3/4 inch holes and (63) 1/2 inch holes. I will be creating 5 toolpaths in Carbide Create … 1 for the 3/4 inch holes and 4 for the 1/2 holes, to be run one at a time as different jobs. This will allow me to take a quick break between sets of holes, but not power down the machine except in an emergency. Unless a feature in Carbide Motion currently exists to select specific toolpaths in a job (please tell me if it does), I will have to generate 5 “jobs” in Carbide Create corresponding to 5 different files. Now …

-

Between “jobs” will I need to redefine the X, Y and Z coordinate of the front left corner of my stock (using BitZero), or will the 5 Pro remember that location between jobs?

-

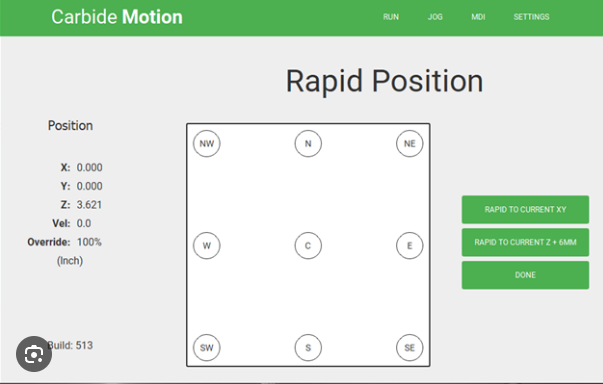

When a “job” finishes it appears that the bit moves up and back away from the stock, but not to the home position. Did I see that correctly and what makes it move there?

-

In running the next job, where does the bit travel to and from? Will it travel correctly from where the last job left it, or do I need to start it from some other position. I would think that it would move to the tool loading position, but where will it start from?

-

Not directly related to the above example, but when one does a machine initialization operation, what really happens under the covers to say the stored zero position of my stock?

-

I had a case yesterday where I manually moved the probe to the inside of the BitZero … but was then confused (newbie) as to what do to next since Carbide Motion seemed to hang (Seems Windows 11 wanted a reset done) and the jog menu was no longer available – only the machine initialization option and I was not sure if the probe would move somewhere directly and break both the probe and the BitZero! I had to remove the bit and then did the initialization operation. The z-axis DID rise, but does the Initialization option ALWAYS raise the Z-axis to a safe spot and if so, how does the machine know what is safe?

-

If between jobs I had to power down and had to reset my stock location, how accurate would the next toolpath job be with respect to the previous job? And back to the other questions, under what circumstances would I need to rerun the PROBE operation to re-zero the desired location?

Some of the above can be experimented with, but would not give me a 100% understanding of what is happening to my zero coordinates within the 5 Pro. In reading a LOT of the Community Posts, the fear of the End Mill doing what you did not expect or understand to happen gives some worries. Besides the machine supposedly doing what you ask it to do, there are always cases where the machine does something you THINK you are asking it to do ![]() AT TIMES I still have some confusion about the job workflow – videos and the like help, but I am not always sure that the 5 Pro’s controller and my brain are on the same page.

AT TIMES I still have some confusion about the job workflow – videos and the like help, but I am not always sure that the 5 Pro’s controller and my brain are on the same page.

Also related to the above, yesterday I failed to press the BitRunner button after starting a job (not sure why I needed to do that reset of the button – will reread the manual), hence the router never started after it asked me to set the speed. It nicely traveled to the initial job location, but I hit the PAUSE button before it began the cut. NOW WHAT? How do I recover from this? What is the procedure? Do I need to reinitialize the machine? Not a lot of Carbide Motion options were available to me. Would the router start automatically once I press the BitRunner button? I had very little breathing space since the bit was right above the stock. I don’t remember what I did, maybe I did a HOME operation. If so, do I need to redo the BitZero operations and reprobe my stock’s location? I am just not sure what the controller will actually do in these special circumstances and what I need to do to safely restart a job. And the documentation is lacking on this point for the 5 Pro. Sometimes I feel like an orphan with the 5 Pro since a lot of the documentation and videos are for the OLDER MACHINES!

Thanks for your time in reading this and providing some answers and helping me obtain a better understanding of what the 5 Pro is doing under the covers. I know there are a lot of questions in the above, but I truly wish that some of the documentation was updated. At least in posting in the Community Section, others may benefit from some of the answers.