Is there a better bit to use besides the 60° Vee bit for lettering? I do not like the circles at the start and end of each letter. Im new to the cnc game so help a brother out! Lol… thanks!

If you can post the C2D file that would help us help you.

Looks like the font would allow a .125 or smaller from my angle. The “V” cut would go to the edges of the text. Your file will help if you are able.

Are you using Carbide Create? If so, post your C2D file.

The circles should not be there, but the reason is not that you are using a 60 deg bit. Changing bits is unlikely to make things better. If we can see your file, we may be able to offer better advice.

What they said… ^^^ Share the file. This looks like it could possibly be 2 things: Limiting the cut depth on a regular V-Carve, and/or using a tool with a broken tip, or a tapered ball mill??

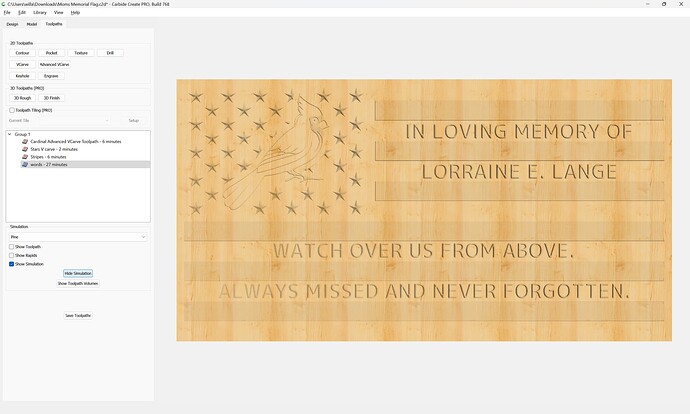

Is the operation that does the stripes separate from the letters?

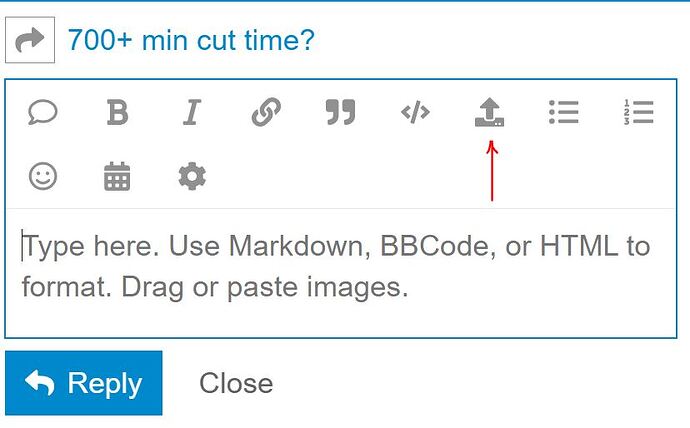

Im using the app and uploading this on my phone. I don’t even know how to share the file on here yet.

Im using the advanced v carve for the strips

I shared the C2D file. Can it be seen?

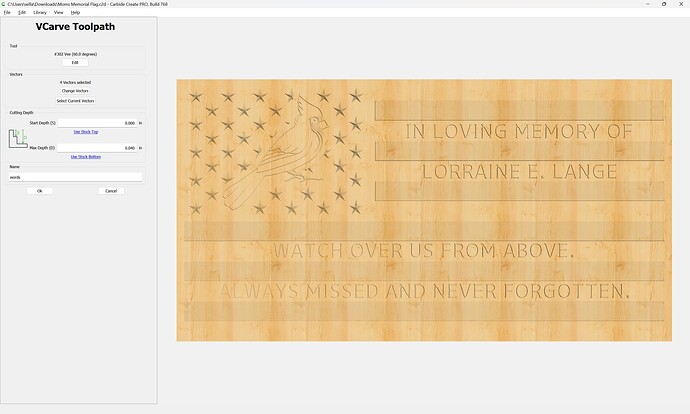

You are using a depth-limited V carving toolpath for the words:

If you remove the depth limit, setting Max Depth to 0.75" (Stock Thickness) you get instead:

To confirm — you were using a 60 degree tool and setting Z zero accurately? Looked like it might have been a 90 and/or a bit low.

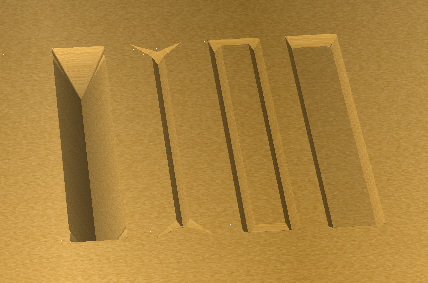

If you want to limit the depth of a VCarve, switch to an Advanced VCarve instead. Limiting the depth of a VCarve never does what you want.

From left to right (each on the same size rectangle) this is VCarve, Limited Depth VCarve, Advanced VCarve, Advanced VCarve with clearing bit:

Im using a 60 and using the bit setter and the bit zero probe to set my Z. Does that answer your question?

I just did 3 flags in a row, is that too much for the router??? The router is really hot and I can hear the RPMs fluctuating.

For using the BitZero see:

for the router being hot and not holding speed that’s probably a bad set of bearings — let us know at support@carbide3d.com if you are still in warranty (12 months).

You have some great suggestions here.

Regarding the router, If you have had it for a while the brushes may need to be replaced. Have you checked them? With continued use it should not be hot. A blast of compressed air from the top might help it some.

I haven’t had the machine for 30 days yet.

Make sure your V-bit stepover is small as possible. Most of the time mine is set to 1% or less. Also verify your Z height is set properly. Also - if your v-bit has any little bit of a flat bottom it won’t carve properly. You would have to compensate on your z height for that as carbide create only calculates v-bit depths with a point.