anyone have a clue about what capacity (cfm, L/min) air compressor I would need to mount a couple of nozzles for chip clearing?

I am presuming that you have considered the issues regarding noise and flying debris that comes with dry air chip clearing, so I would say that for the Nomad, you could do with pretty much any small compressor. You will not need large nozzles.

For example: at 2bar (30PSIG) pressure and 1mm dia nozzle, 30C (85F) air will flow about 22l/min (0.75SCFM). A small homeowner compressor for a nail gun will supply that.

Two nozzles of 0.5mm dia will discharge about 11l/min (0.37SCFM)

This is the best I can tell you without knowing more about the nozzles you plan to use.

You may end up burning it up if you constntly run a blower… I suggest a decent tank with the lowest psi that will clear chips. Someone on here did an oil can attachment for wd40 i think a small apparatus like that mounted onto the router mounting bracket would be sweet.

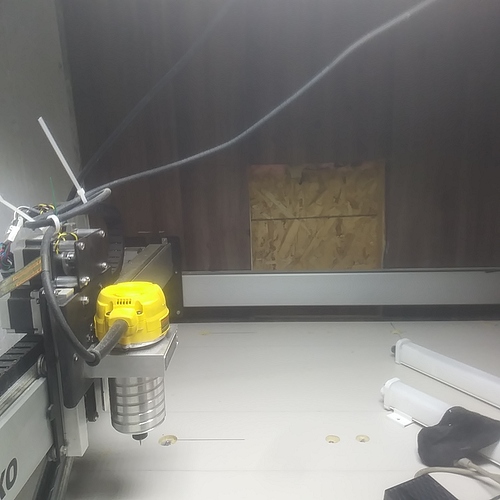

I am boxing mine in currently with a 6" centrifugal fan sucking air from the box out anda blower blowing air in at the worktable.

well the plan is to have a vacuum as well but I thought that with some air I could run the vacuum on “quiet” or not at all when I’m milling small volumes non-dusty stuff like plastics.

and yes I was thinking about something in =/< 1mm dimension.

After some more research finding a good super quiet compressor that doesn’t cost to much and can run continuously seems to be the biggest challenge. I am not building a nice cabinet for the machine only to have a 70dB+ air compressor ruin my day.

A decent vacuum ought to be able to do a good job of clearing the chips — I’m still curious if you could improve chip clearing by venting the air from the trim router right at the endmill — drew up a design for that, but it really wants to be 3D printed.

I have an air compressor that is hammering loud when it’s on and a tank that empties far too quickly. I was pondering at one point (before I decided blowing air inside my Nomad just made things far too messy in places I just could not clean) whether a beefy aquarium air pump might be up for the job pressure wise considering they are usually quieter and designed for constant operation.

that might actually be a great option… and yes I’be been thinking about the mess but I figure some of that folded rubber stuff (what is it called?) in strategic places and optional vacuum attachment will solve that.

found one “ACO-9720” it supplies

21,5 l/min at 0,13bar

max pressure 0,27bar

<40dB

I have no idea if that is enough air and pressure though if:

is the goal… then nope…

At the business end, you have traded pressure for momentum. The aquarium pump may be sufficient with a larger nozzle. Machining conditions control the air velocity and volume needed. The puffer on my die filer moves maybe 10l/min (based on displacement and speed and about 50% volumetric efficiency), and the nozzle orifice is about 2.5mm. It is built in and run from a cam on the mainshaft, so I don’t know the pressure. It moves steel chips just fine in filing operations, but I do not think it would lift chips from a pocket.

I guess like with most things the only way is to try it…

with a larger nozzle I might need to put some googling in to laminar flow

I have an exhaust fan sucking air out of the enclosure and a blower fan blowing air in. They’re in line kinda. Blower up top blowing down, centrifugal fan on the other side of the wall sucking air out through a stud bay… I would say its a major improvement but still needs some caulking in a few spots to maximize airflow.

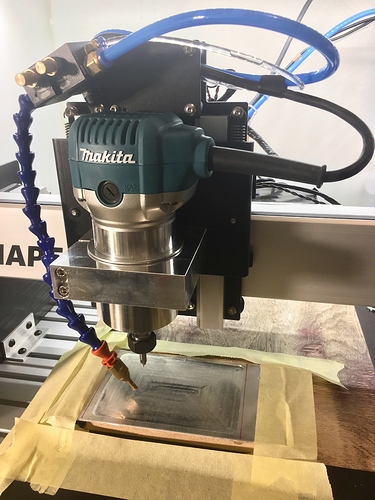

I run a Hyundai Silent oil free air compressor that is produced and sold under many brands. This particular model makes 135 l/min at 8 bar and has a 24 l tank.

At the business end of the Shapeoko I have this setup:

I use for engraving 1bar, for milling about 2-2,5 bar plus ethanol if necessary. With these settings and the nozzle relatively close to the end mill I have great results but the compressor works more than it should. I decided to actively cool it with a blower fan to keep it cold.

If the only reason is to invest in a compressor is to clear chips than you have better solutions. (Bit fan or dust shoe)

I am making a dust shoe but I’m having a hard time seeing it getting chips out of pockets in a timely manner especially since I’m not going to run my vacuum at max (no shopvac and… neighbors).

This is more of a “is this a waste of a 100$”?

I should mention I am milling mostly plastics so maybe 0.2bar@31l/min 0.38bar max (the larger model) is enough…?

bitfans… ppbly works for the 30k rpm of the makita but the nomad tops out at 10k…

A cheap solution will be expensive in the end. I also bought a 12v bike compressor at first which was a total failure. The pressure and wolume you wrote will not be enough for sure, other than keeping clean an engraving bit. For a hundred (140 at the most) you can get a silent air compressor that is not louder than 65db (wife and neighbours will appreciate) and that can be further suppressed if necessary.

This is what I have (but blue and Hyunday) and I recommend it for hobby use:

California Air Tools 8010 Ultra Quiet & Oil-Free 1.0 hp Steel Tank Air Compressor, 8 gal, Silver https://www.amazon.com/dp/B00WM1VPKE/ref=cm_sw_r_cp_api_i_QLIdBb8KH8TNS

I don’t know how large plastik pieces are you milling but my experience is that doing such projects requires a decent dust extraction also; at least the Shapeoko does but I have no expreience with the Nomad.

I just used a old quincy 120 gallon tank compressor. You can probably find one cheap.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.