definitely inconsistent pressure of some sort and with such little room for error a screw driven Z may be necessary.

I kind of doubt this explanation as I tried different depths varying by more than 0.1" which I don’t think produced anything like this dull effect. Seems unlikely a much smaller variation in depth produced by an error somewhere could produce it.

I don’t know much about engravers but in my experience surface finish problems usually are related to chip clearing.

I considered this, but that wouldn’t explain why the dull section always tends to be toward the bottom, or why it seems to be getting worse over subsequent jobs.

you might also have a flat spot on a v wheel. Can you mark the X-Y orientation in the picture

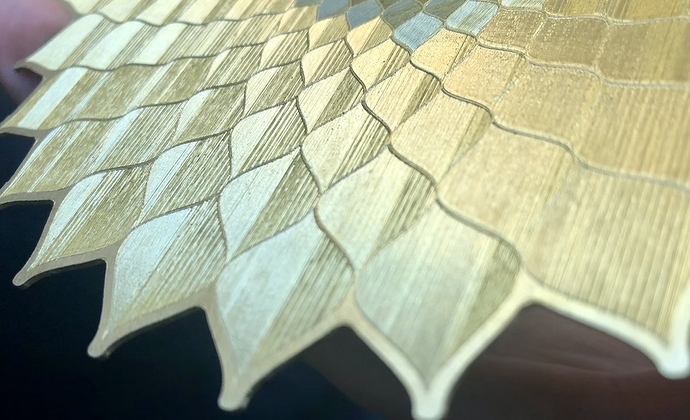

1: Right is bottom

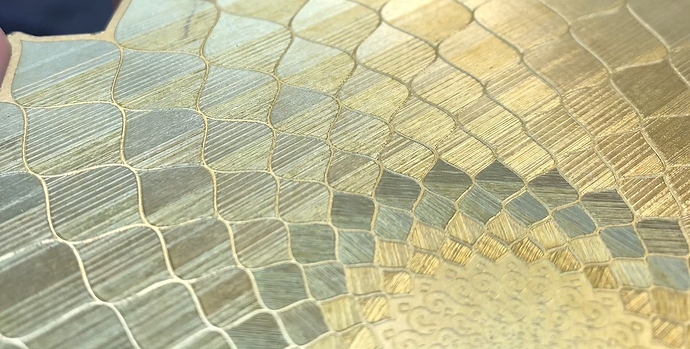

2: Not sure

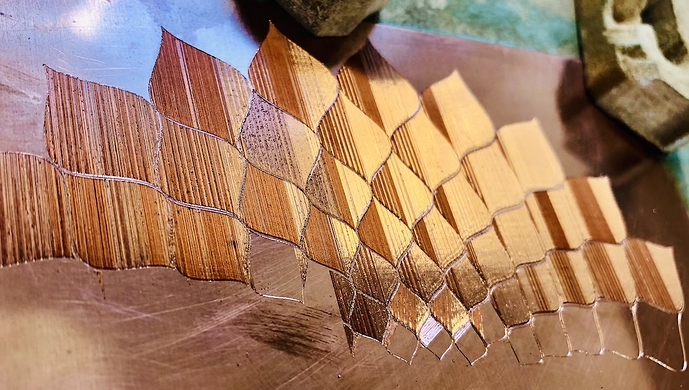

3: Left is bottom.

Again, hard to explain the bottom of these shapes usually being the dull part with a flat spot on the wheel.

Can you tell me a little something about your spindle/router? Brand-name, model?

It’s the Makita that Carbide3D sells.

Could you inspect the different surface finishes with a microscope as well? That could be quite revealing.

I did. Pictures in the first thread. I couldn’t discern anything from them.

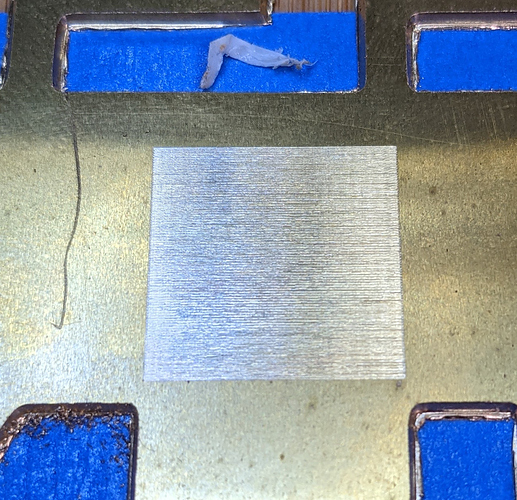

The intention here is to see if small deviations in the depth of cut lead to the effect you’re seeing.

I tested this some time ago but can try again once I get my CAD machine fixed (I broke the partition somehow.)

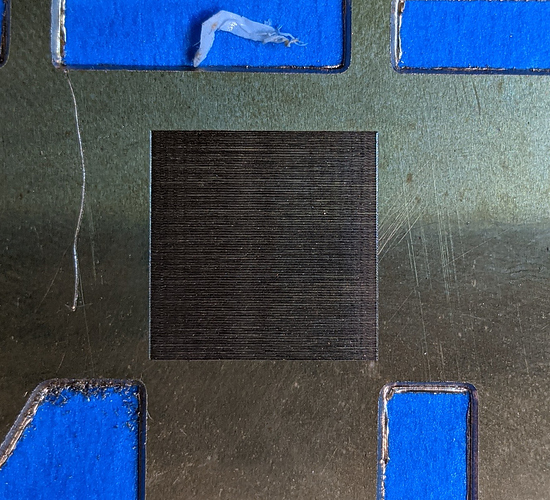

Is every line parallel and the same distance from its neighbour? It’s hard to see in the pictures but the patter does not appear to be regularly spaced.

There’s some wobble in the lines if you look at the microscope photos in the first thread, but not a ton. The earlier jobs that didn’t have this problem don’t seem to be any straighter.

One possibility is that the metal is beings scribed for some cuts, but deformed for others. So cutting a V shape into a flat surface gives one result. Scribing a V next to another V bends the metal on the existing V since it’s very thin, especially at the top. Or putting a V between two V’s bends both sides. Each then produces a different reflections.

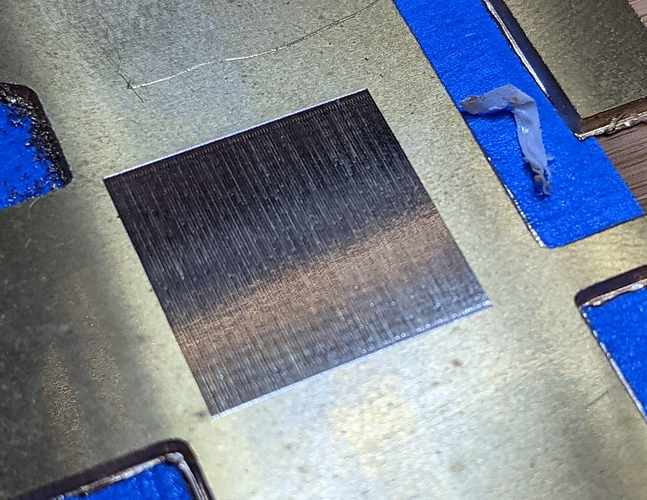

Interesting theory. I considered something like this, but still not sure why it would suddenly start happening… Maybe my pitch is too tight. These are around 3 thou between the center of each line. Once I fix my CAD machine I’ll try running some different pitches. The weird thing is I ran a piece with a bunch of different test pitches and none of them had this issue. See image:

I might have missed it in this thread or the earlier one, but can you confirm you are using a spring-loaded diamond-drag bit ? 99.99% sure you do, but still asking.

That’s right. I’ve tried a new bit too. Spacing is 0.003.

Could the tip of the DDB not be perfectly circular? Maybe it has facets, and as it drags back and forth, it is rotating in the spring loaded body and creating the different scratch geometries? Maybe put a sharpie mark on the shaft of the bit itself and see if it is rotating.

Already tried this with a piece of tap. Couldn’t see any rotation happening.

would you mind sharing a tiny sample of your G-code (that would for example be limited to a single “leaf”), for me to run that and see what happens?

To be honest not sure how to do this. The gcode file is 200k+ lines and the leaves aren’t done sequentially - it jumps between them.

In your CAM, does the DDB move in a raster pattern between left and right, or always in the same direction?

Usually the same direction but I think I’ve seen it go the other way too. I already checked to see if the dull spots were created by it traveling in a different direction from the bright spots, but that doesn’t seem to be the case.