Hi Folks,

I’ve got an XXL and I’m working on a series of pieces with very dense diamond drag engraved lines (0.004 - 0.003 line separation). I understand the Shapeoko tolerance is around 0.005", but this isn’t an issue with absolute performance.

My first piece looked the best, with a few errors where the machine put the next line too far, but I’ve noticed that the errors seem to be getting worse with subsequent jobs. These are long jobs - 6-10 hours each, so it would make sense to me if there’s some kind of wear or loosening happening somewhere.

Here are some photos:

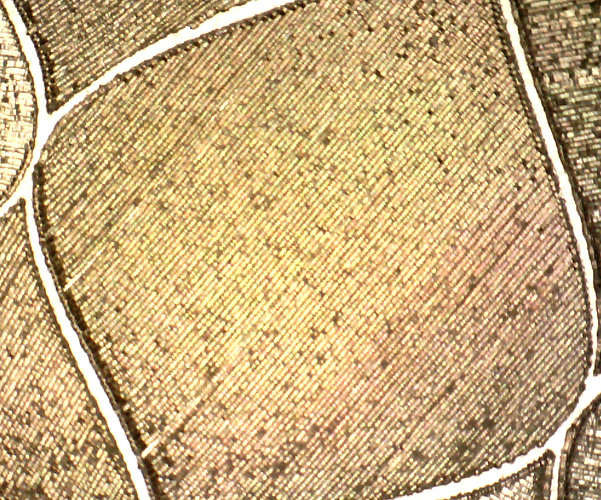

First job:

Magnification:

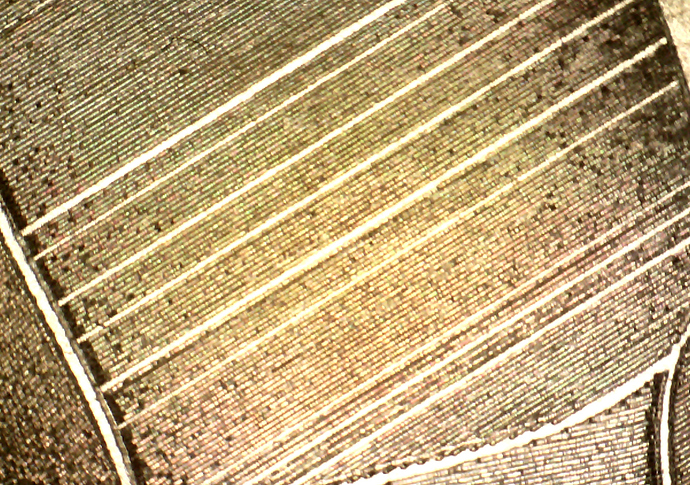

It still had some errors, not but many:

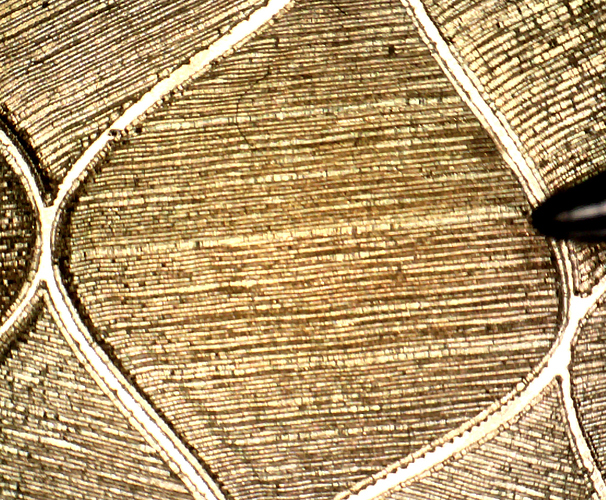

Then I did my second job, and there were more lines, plus in many of the shapes, the engravings look different (darker or lighter) on one half of the shape.

Magnification doesn’t reveal much. The pen tip here marks where it goes from light to dark, and there is a line there, but either side looks like of similar under the microscope lighting:

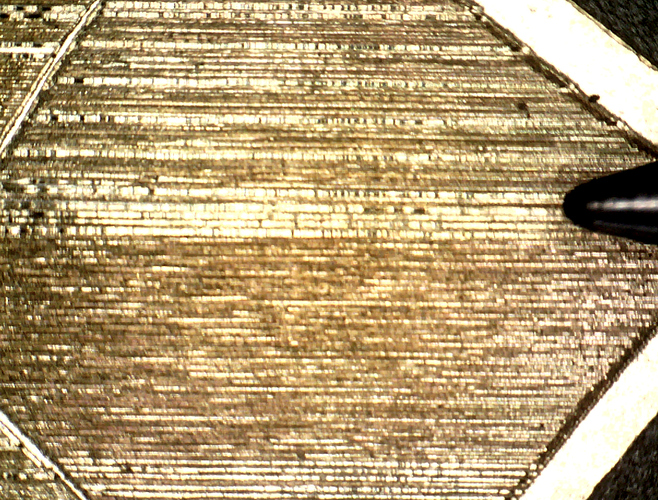

And the third job is worst yet, where almost every shape in it has half light and half dark lines:

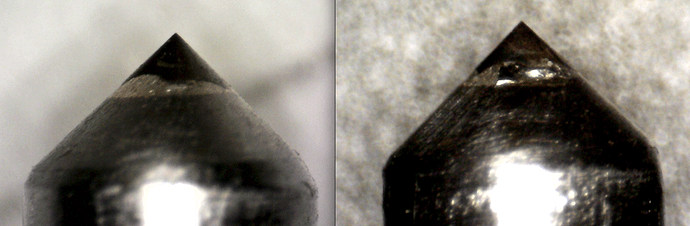

It’s not the bit that’s wearing. Here’s a picture of the diamond tip before and after - it’s pretty much unchanged:

Would appreciate any insight on what’s going on and what I can do to fix it.