Aha,

For belt stiffness you’re looking for the tension modulus, reported as extension for a given tension force

I found that after reading the excellent thread where the real janderson used some real equipment to measure some belt samples

In my simple deflection model for the Shapeoko (the spreadsheet I uploaded to the deflection backlash and vibration thread) I use a belt tension modulus for 9mm kevlar / steel cored belt of 0.019% extension per kg ‘force’. I apologise for this horrid muddled unit but I was converting back and forth to lbs force which our American friends seem determined to stick to ![]()

The Gates docs do, I think, walk through some calculation of belt stretch on the power (tension) side, you work out the belt distance under tension, not touching the pulley teeth, then apply the tension force and work out the extension, if you start with 0.002% per Newton that’s Kevlar / Steel GT2 9mm.

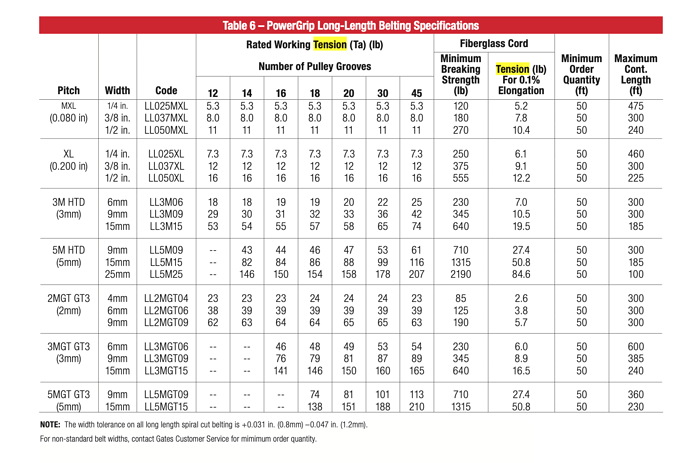

If we take the Gates sheet data, 5.7 lbs force for 0.1% extension, that’s

5.7 * 0.454 = 2.59 kg

2.59 * 9.8 = 25.4 N

0.1% / 25.4N → 0.0039% belt extension per N tension

Which is about right for the polyester core vs. Kevlar or steel core.

Does that help?