Has anyone found a source for 15mm wide 2gt kevlar reinforced belts? All I have been able to find are the standard fiberglass ones. I have found steel core but I would prefer kevlar.

like these?

Do they ship outside Australia?

They have an email link on the website, would imagine that would do the trick.

Very close, but not 2GT standard. The 2GT has rectangular teeth where that one has round teeth.

Ali express has some 6mm and 10mm width, still looking for 15mm…

My understanding is Gates GT2 profile (our pulleys want 2mm pitch) is a rounded profile, see:

I was confused by the nomenclature and thought there was a typo somewhere. But, interestingly, both GT2 and 2GT exist, but GT2 is not 2GT. Though Gates make both. Confusing

(neither GT2 or 2GT have rectangular teeth though)

Yes, it is most irritating, almost deliberately confusing.

Gates had the GT2 belt line for light power transmission and precision drive. Within that they have 2mm, 3mm and 5mm tooth pitch belts, the 2mm being 2MGT and the 3mm being 3MGT

Gates then decided to upgrade the belt design and call the new one (with apparently the same tooth profile) GT3.

So the old belt was a 2MGT GT2 belt and now it’s a 2MGT GT3 belt.

Of course when I was ordering and using the big brother 3MGT belt that made it all the more joyful, especially as apparently none of the eBay or AliExpress sellers care about the difference and half the Gates resellers don’t seem to know either. For the Gates belts, just go by the part number.

As Will says the tooth profile is rounded, there are very good reasons for this. The Gates tooth profile is particularly clever as it both minimises sliding friction as the belt wraps into and out of the pulley and provides almost zero camming or ‘jacking out’ force on the teeth meaning that with even very low belt tension there is little risk of stretch induced tooth slip. (unlike a Philips head screw as previously discussed with Will ;- )

I happen to be looking for belts now, did you manage to find a seller that sold what you needed?

I found several, some in the UK, there were more Gates OEM distributors in mainland Europe, but I also bought a bunch of decent clones from AliExpress, what sorts of belts / pulleys are you after?

This is an excellent resource if you’ve not seen it

Hmm, I wasn’t able to find much that was reasonable. I’m looking for 2MGT or 3MGT belts, 9mm or 15mm diameter and pulleys for a 2:1 belt reduction. UK or mainland Europe is fine, I didn’t have luck with either. Even Aliexpress is full of HTD belts.

I’m upgrading my machine to servos and I think 3000 RPM is a bit much with 5mm ballscrews (15000mm/min).

I found a few places (like here) that had the belts but finding the pulleys is a massive pain in the butt.

5mm ballscrews? Do you have a spec for the max RPM on those screws over the distances you’re running? There’s normally a vendor spec for that, on the upside Nomad size is going to keep you well under a meter

As for the belts, the Gates guide shows you the torque and power they expect to transmit per unit belt. If you do the dynamics calculations for mass being accelerated (including rotating mass of ballscrew) you should be able to figure out the forces the belt needs to cope with. I think it’s unlikely that you’ll need 15mm width, if you do then I’d go from the 9mm 2MGT to the 15mm 3MGT as that is all round a much less stretchy and stronger belt (it’s what I have on my X axis now). Check the Gates guide to see how much more backlash there is on the 3MGT profile, then divide that down by the pitch on your ballscrew to see if you care.

I found that using larger pulleys helped me tension up a system with minimal backlash, you get higher belt velocity but for any given backlash in the belt system it is acting at a greater distance from the shaft so the rotational backlash is reduced. My initial attempt used small pulleys in the 20T to 40T range and I found I needed quite a bit of tension to get those backlash free, so I went larger. As the diameter increases the drive tension on the belt also reduces for the same drive force but calculating the belt extension for these short lengths resulted in “small number” for me.

You should design something that lets you put controlled tension in, either a dedicated tensioner or the motor mount should have a screw type tension adjuster ideally to let you dial it in consistently.

As for the pulleys, the OEM gates are good I have also used some from the eBay UK seller CNC Planet who is really helpful and sells good stuff. The ones currently on my machine are mostly Powge from AliExpress.

Belts, I got some of the real Gates belts from this seller in the UK, not the fastest but they’re the real thing and the Gates belts are good quality

https://buybearings.co.uk/product/gt3-168-2mgt-3-gates-powergrip-belt-2m-pitch-3mm-wide

I believe @jepho found another source of the OEM Gates belts as well.

To find the Gates resellers I ended up using the Gates part number, e.g. “Gates GT3 168 2MGT” and Googling for that turned up the resellers in my region.

Gates tech support in the US are really helpful, the UK support team took rather longer to respond to questions.

For Chinese import I have found that the Powge belts and pulleys from AliExpress are good quality, there is the “Powge Official Store”

https://powge.aliexpress.com/store/702327

and also the “Powge Transmission Parts Store”

https://powgebelt.aliexpress.com/store/528282

which both seem to sell the same parts, no idea what the difference is but I’ve purchased from both and been happy.

You might also spot the “Powge” logo on the belts on the Shapeoko Pro…

Regarding ballscrew rotation speed, they say <ballscrew diameter> x <RPM> shouldn’t exceed 70000 and that’s about it. So with a 1605 ballscrew, 4375 RPM is my limit.

And I agree that 9mm 2MGT is almost certainly enough but I have dreams of doing crazy things to my machine like sticking on an 80mm spindle with ATC in which case I might want a bit more stiffness in my belts. I couldn’t find backlash numbers in the guide you linked though?

I’ve been looking at giant pulleys out of necessity unfortunately, that’s a big part of the problem. My servo shafts are 14mm and the only pulleys that support bores that large are enormous. But on other hand, I don’t want too large a pulley on the ballscrew because that makes designing the axis as a whole a bit more painful.

I’ve seen a lot of stuff on this forum about tension so I’m very aware of the need. My plan at the moment is to add an idler on top of a stiff spring that can be adjusted by one grub screw and locked into place with another. That should allow me to apply a reasonably precise but consistent force to the belt.

Thanks for the supplier recommendations! I’d looked at POWGE in the past but couldn’t find what I needed from them. I was looking at the 3GT section which looks pretty empty but the 2GT section is apparently pretty full! The others look good too. I like the eBay seller but the problem with most of the European sellers is that they take so long to ship that I may as well just order from China…

You can get pulley bar stock…

Online Product Catalog – Timing Belt Pulleys – Bar Stock | Pfeifer Industries

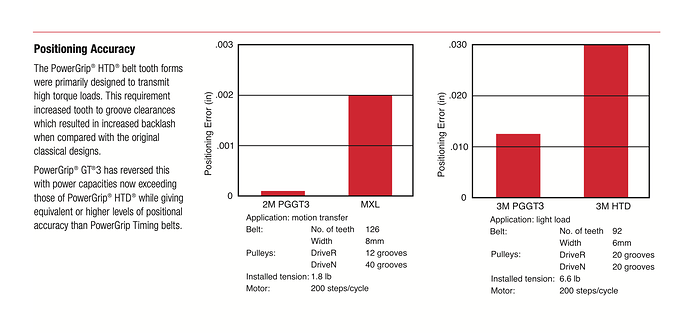

Here’s the backlash chart

Beware! - the vertical axis on the right hand chart is wrong, it should read 0.001, 0.002, 0.003

I would not expect belt backlash to be an issue for you, assuming it’s tensioned well (meaning consistently not necessarily uber tight and fracturing ballscrew shafts).

If you see the 0.0025mm backlash * 2 for 3MGT on a, say, 40mm diameter pulley, that’s 0.015 degrees on your ballscrew which would come out at 0.0002mm on a 5mm pitch ballscrew, measuring that will require some care to measure at all…

The belt tension extension during acceleration is worth calculating though as this could be a non-negligible number with those beefy servo motors.

I tried a few tensioner pulley options on mine before looking at a bunch of the CNC builder forums and seeing that everyone else just uses slots for the motor position and a screw to push the motor out to get tension with fewer components. If you build your own tensioner you need to be careful to ensure that it’s not going to deflect when it’s on the drive tension side of the belt vs. the slack side and create backlash that way.

I can get bar stock but I don’t have a lathe so I’m not confident about boring the inner diameter. Concentricity on the pulleys is important because if they’re a little bit eccentric, the effective diameter is constantly changing as they spin. Plus, you need to hold a tight tolerance on the hole to get a decent fit on the shaft.

Ahhhh, right. There’s going to be a slack and not-slack side…

In that case yeah, I think I’ll see if I can build a slider into my motor mount and adjust it with a grub screw.

They’re not super beefy, I bought them mainly for precision. Rated torque is 1.27Nm, peak torque is 4.45Nm. Looks like the smallest pulley I’ll be able to stick on it is ~30mm diameter, so peak force exerted on the belt would be about 300N? I don’t see any numbers for belt stiffness though…

Hmm, it looks like 2GT belts might not make a lot of sense for a CNC. The rated torque for a 45-tooth 6mm-wide 2MGT sprocket at 1000 RPM is 1.58Nm. 9mm is 1.64x that, so 2.59Nm.

However a 3MGT sprocket with the same parameters save for 30 teeth (matching diameter) is 2.44Nm for 6mm or 4Nm for 9mm. That’s 1.54x the torque in the exact same size.

But that brings the original problem back: it’s nigh on impossible to find a 3GT pulley with a 14mm bore…

If only I could just use the regular 5M profile pulleys. I can get those anywhere.

Aha,

For belt stiffness you’re looking for the tension modulus, reported as extension for a given tension force

I found that after reading the excellent thread where the real janderson used some real equipment to measure some belt samples

In my simple deflection model for the Shapeoko (the spreadsheet I uploaded to the deflection backlash and vibration thread) I use a belt tension modulus for 9mm kevlar / steel cored belt of 0.019% extension per kg ‘force’. I apologise for this horrid muddled unit but I was converting back and forth to lbs force which our American friends seem determined to stick to ![]()

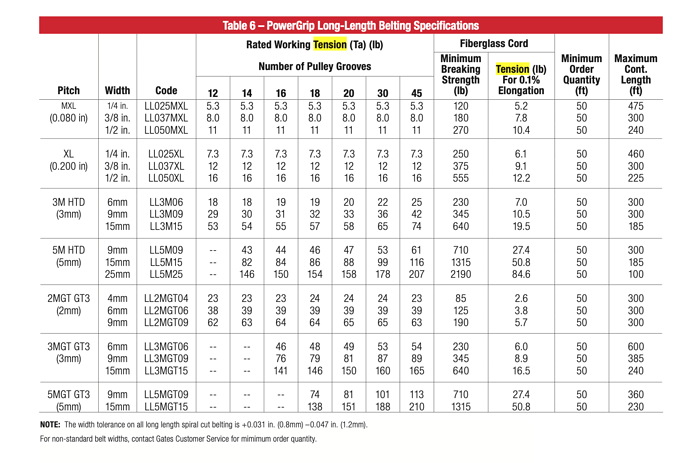

The Gates docs do, I think, walk through some calculation of belt stretch on the power (tension) side, you work out the belt distance under tension, not touching the pulley teeth, then apply the tension force and work out the extension, if you start with 0.002% per Newton that’s Kevlar / Steel GT2 9mm.

If we take the Gates sheet data, 5.7 lbs force for 0.1% extension, that’s

5.7 * 0.454 = 2.59 kg

2.59 * 9.8 = 25.4 N

0.1% / 25.4N → 0.0039% belt extension per N tension

Which is about right for the polyester core vs. Kevlar or steel core.

Does that help?

So if my numbers are right:

- 45-tooth 2MGT sprocket = 90mm circumference = 29mm diameter = 14.5mm radius

- 4.45Nm x 14.5mm radius = 307N = 69lbf

- From your sheet

- 45-tooth 9mm 2MGT sprocket has a working tension of 63lbf, a breaking strength of 190lbf and a modulus of 5.7lbf per 0.1% elongation

- 69lbf/5.7lbf = 12.1, 12.1 * 0.1% = 1.21% elongation

- The belts I’m looking at are around 180mm long, the section under tension being around half that at 90mm, so the amount of stretch I’m looking at is 1.21% of 90mm = 1.089mm

- 1.089mm is 0.00605 of a rotation of a 90-tooth sprocket (this would be on the ballscrew for the 2:1 reduction)

- 0.00605 of a rotation of a 5mm-pitch ballscrew is 0.03mm

So with the 9mm 2MGT belts I’m looking at ~30µm of peak stretch-induced imprecision for my application.

With 9mm 3MGT belts, I’d reduce the belt-induced imprecision to about 20µm, with 15mm 3MGT belts, to 10µm, with 9mm 5MGT belts to 6.24µm and with 15mm 5MGT belts to 3.36µm.

In the thread you linked there’s talk of much better performing steel-cored belts and talk elsewhere about Kevlar/aramid but Gates doesn’t seem to manufacture steel/kevlar-core GT3 belts, so how does one obtain them?

Bringing us back to the original topic of the thread