This was a fun project. Something I’ve been meaning to do for quite a while. I’ll use some of them as prizes in an upcoming contest.

I have a 3" disk with a 1/2" shaft that I use all the time. It just barely fits in the sweepy, so I have to put the sweepy on, move it up, load the tool & slide the sweepy down. Tedious, but it works.

I thought a 2" disk with a 1/4" shaft would be much more practical, so I made some.

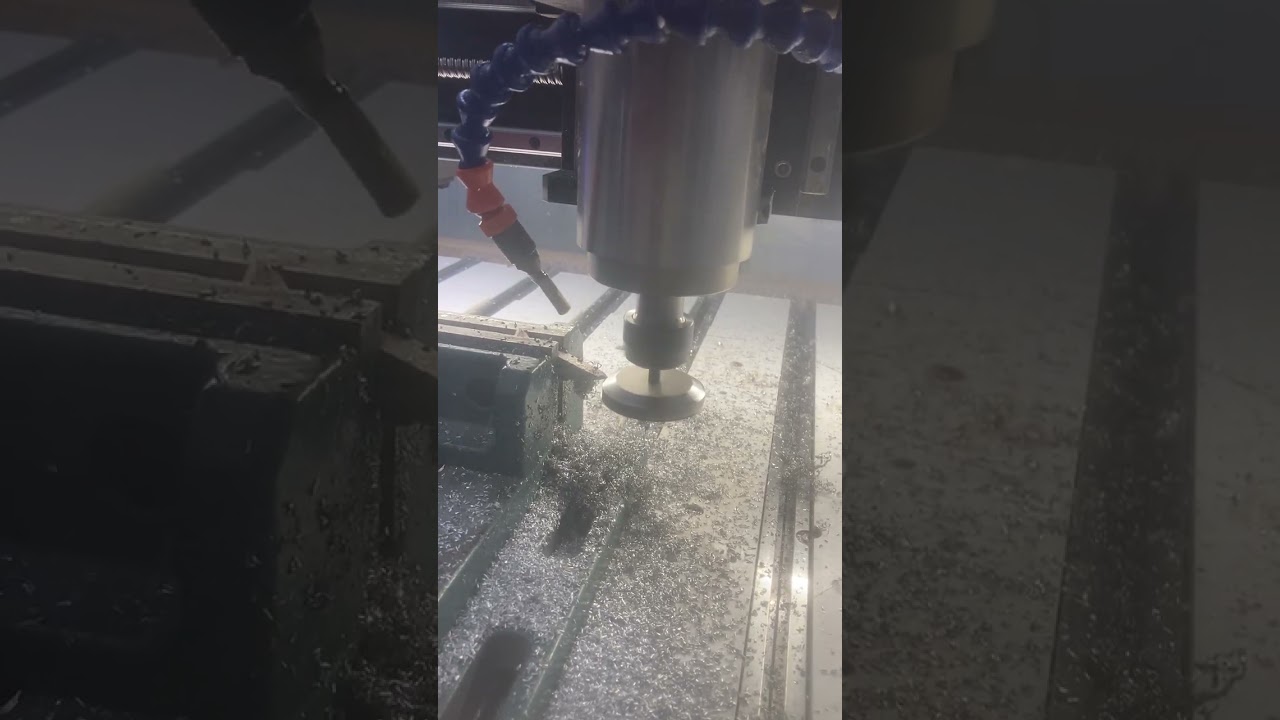

Several unique processes were used. I cut out the blanks from 3/8" 6061-t6 aluminum to 2.020"

I used hole-milling* to make the mounting holes and thermo-fitted them. I calculated the thermal expansion of the aluminum, which came out to 0.0015" for a 1/4" hole. So I cut the holes at 0.2485". Since my shapeoko HDM doesn’t have cutter compensation, I create a path starting at 0.2475 increasing 0.0005" with each pass and a optional stop between passes to measure. When it’s within tolerance I just stop the program.

I heated the blanks to 550° and inserted the shafts (hardened dowels) and let the aluminum cool.

The next fun part was turning the angle, OD, and face. I used my HDM like a lathe, repositioning a fly cutter bar for each cut.

*Hole milling can be done in Carbide Create with a contour path, inside offset. Set the plunge & cut feedrate the same, set the depth per cut greater than the max depth. Use ramping with an angle that results in the depth per cut you want. I used 1.5° to get about 0.010" depth of cut per revolution.

Keep an eye for a contest coming up soon to win one. They can be used with 2" self-adhesive sanding discs readily available. I recommend 40 or 60 grit.