Hey guys, I’ve been working on an officially-sanctioned-but-still-unofficial dust management device for the Nomad. Previously I’d designed something that would take a vacuum hose and basically clamp it to the spindle, which was good enough to capture the airborne nasties that would escape from cutting MDF and stuff, but didn’t have a brush. Enough people sounded like they really wanted that extra option so I threw a concept together.

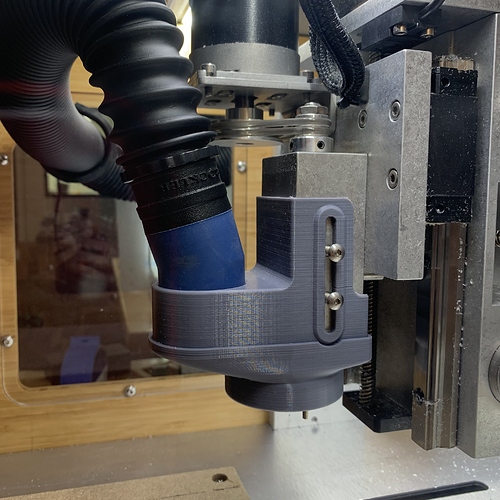

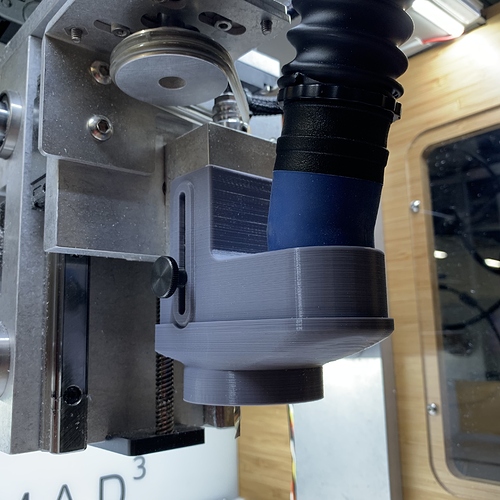

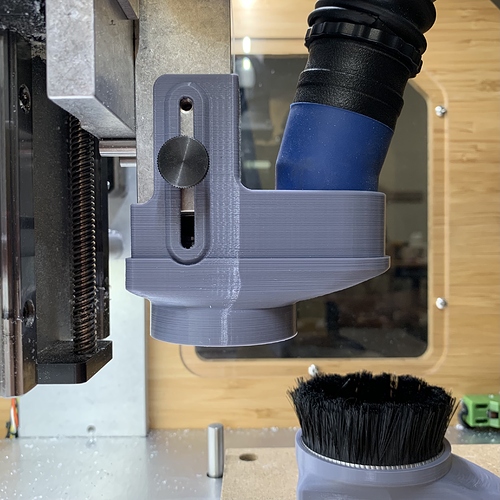

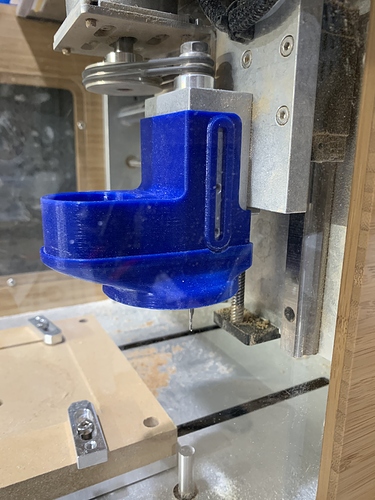

This is a two-part dust shoe that works just like Sweepy. On one side I use some oversize M4 hardware (anything longer than 1cm should be able to bottom out in the hole) for the base piece to slide on.

On the other side I use 1 or 2 M4 thumbscrews to lock the shoe at a fixed height.

WARNING: Officially, I must dissuade you from adjusting the dust boot while the machine is in motion. If you put the thumbscrews on the left side like I have here, you can get a nasty friction burn if your fingers touch the spindle pulley… I have them on the left so I can easily access them while the spindle is in the “home” position to the right. It’s a personal choice.

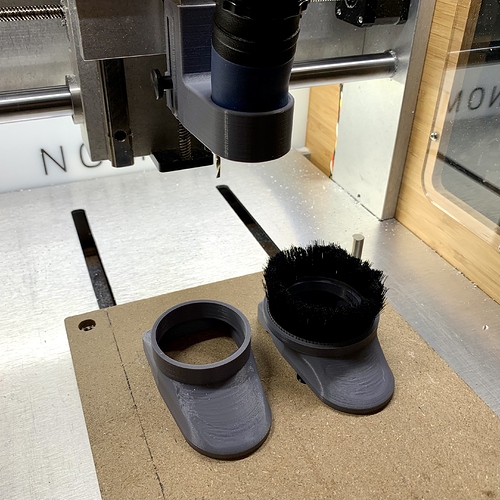

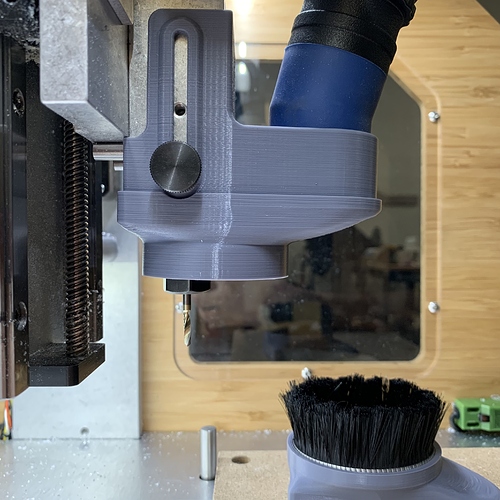

There are two variants of the shoe bottom, one with just a narrower ring when you don’t want a brush in the way. Should fit flexible strip brushes you can find on McMaster, or the brush rings in the Sweepy 65.

This is designed specifically for the Rockler Dust Right FlexiPort Power Tool Hose Kit, which is the softest, most flexible hose I have ever seen. I made a little printable clip you can use to route the hose out of the enclosure. Cutting a hole in the side window is optional. You could also use a Forstner bit to make a hole in the side panel.

At the highest position, it should put the bottom of the dust shoe above the collet so you can mill with a fairly short tool without fear of collision.

Provided below are STL files for all components + Fusion file for the mounting base so you can tweak the vac port size (ex. shrinking to 35/36mm for Festool hose). Consider this shared under CC BY-NC-SA 4.0. Your mileage may vary, no support will be provided.

Files hosted on my site because forum limit is only 4 MB

You will need to provide:

4 - 1/4" (6.35mm) x 1/16" round disc magnets

2 - M4 screws > 10mm in length

1 or 2 - M4 thumbscrews < 10mm in length (ex. https://www.mcmaster.com/92581A230/ )

1 - Brush strip

3D Printing Comments:

You may be able to get away without support if you’re smart about it. Otherwise I’d suggest limiting support to “Touching Buildplate Only” and for areas steeper than 80 degrees. I print all components in their normal orientation (on the dust boot, the bristled part faces downward) to minimize the need for support.

If your printer tends to over-extrude or have elephant foot-ing, you may need to lightly sand areas of interference with the spindle block.

You may also want to use a 1/4" endmill to ream the magnet pockets to ensure the press in smoothly. Use CA glue to lock them in, and a piece of plastic to press them flush.

Recommend a wall thickness of 3 layers (1.2mm w/ 0.4mm nozzle).