Me too!!

“I guess I’m going to have to find a way to keep my Suckit down against the wood. .” That’s my take on it, but I’m certainly no expert.

“maybe add on a gate on the back side where the slot is for the bit to pass through” The latest Suckits have that.

“I guess I’ll have to find a small USB camera to tuck in there to watch what’s going on inside the Suckit.” Great idea - record the video for replay to see when things go good/bad?

“I am still going to finish and print the 4in dust shoe just because I have already started it.” Another good idea - “the proof is in the pudding”.

IMO, if you can keep the Suckit down against the workpiece, your dust collector should do a good job with either 2.5", 4", or 6" connections if you keep the other blast gates closed. Try it?

This 100+ MPH dust stream created by the blade is fairly low CFM. And any dust able to achieve and maintain that sort of velocity isn’t respirable (they’re larger chips that hit the floor fairly quickly). The finest stuff won’t get very far before the DC grabs it.

Forget most of the scare tactics of BP, in my opinion most everything was proven absolutely false once hobby shop owners were able to get inexpensive particle counters.

Keep in mind duty cycle with these.

Usually dust collectors have a higher duty cycle than shop vacs.

Don’t want to burn up a motor.

Those prints look awesome!

Was I completely off base in thinking a 4" tube from my dust collector to my router’s dust boot w/ an enlarged opening (and a higher volume of air being moved than a 2" opening w/ a 2.5" tube) would be beneficial in capturing more of the fine dust? Providing that the brush on said dust boot is in contact with my work piece.

Yup! A 1/8" kerf blade cutting 4" thick MDF at 100 IPM generates 50/(12X12X12) = 0.0289 CFM of sawdust and requires about 1.5 hp. That’s why vacuums, which offer hundreds of CFM (vs the thousands of dust collectors) are more than the adequate if dispersion of the dust/chips is properly controlled. Rather than use power to produce unnecessary airflow (analogous to current) at low pressure (analogous to voltage), vacuums use the power to produce higher pressures at reduced (but still overkill) airflows. That increased pressure is useful in overcoming the pressure drop in the ductwork. That’s part of the “magic” of Festool.

“And any dust able to achieve and maintain that sort of velocity isn’t respirable (they’re larger chips that hit the floor fairly quickly). The finest stuff won’t get very far before the DC grabs it.” If something isn’t used to block the dust/chips from the top of the sawblade in a table saw, a cloud of dust quickly appears near/around the operator. The dust collector can’t do anything about that. Gravity eventually causes the heavier particles to fall out of dust cloud but has negligible effect on the lightest (most harmful) ones.

“Forget most of the scare tactics of BP, in my opinion most everything was proven absolutely false once hobby shop owners were able to get inexpensive particle counters.” Got references?

Only if the dust is able to to achieve what I call escape velocity, quickly getting beyond the envelope of evacuation. The finest dust likes to meander, it doesn’t shoot in a straight line very long. Meanwhile, a 400-CFM hood is evacuating a 9’ sphere of air every single minute, or a sphere approx. 4.3’ every single second. So unless the respirable dust can make it past this point, it is likely going to get collected.

Even if some DOES briefly get beyond that point, make-up air will likely bring it back to the hood in short order.

I don’t have links for the Dylos particle counter buy threads, you can likely google them. They’re from some time ago, maybe 2008 I guess. If you go back to before this point in time on many of the woodworking forums, you can find lots of concerned woodworkers that were told their shops had never-settling fine dust that would eventually be their undoing. My recollection is that maybe eighty or so people got Dylos meters in the first go, and they all pretty much reported that the Dylos showed their shop air was cleaner than the air in the rest of their homes, or even outside.

Isn’t the 400 CFM hood in the saw’s cabinet (under the saw table)? How does that have any effect on the top of the saw table? ![]()

You only need bright lights (like sunshine) to see the dust cloud and how it disperses. Too bad you can’t see how much (and what types) of it gets inhaled by the operator and others in the shop. But at least they can sometimes smell it, cough it up, and/or have an allergic/toxic reaction to it later! ![]()

When the saw is cutting, dust is brought by the teeth to below the surface of the table. On many saws these days (my inexpensive Ryobi included) there is a shroud around the blade. Some dust is ultimately carried back out of the shroud and to the top of the saw again, but with the DC running that air is rather quickly evacuated to below the saw where the hose attaches.

A demonstration I’ve done for people in my own shop, when I still allowed visitors and they were here in the winter evening when it was dark, was to take a few passes on the edge of a board w/o the DC running. Then we’d turn off the lights and turn on the DC, and I’d hand them a flashlight. They could see the dust-laden air moving towards every opening on the table saw.

Even more spectacular, when I had it, was the drum sander. That was dust cloud creator, but the same result. The air around the tool was evacuated, carrying the dust with it.

That’s a good argument for HF Spindles instead of routers too! (Or purchase with credit cards that extend manufacturers’ warrantees.) ![]()

“Those prints look awesome!” Thanks, but tables are just standard Excel stuff and the chart came from Clear Vue. ![]()

very true. i’ve heard and experienced typical shop vacs to fail moreso than i’ve seen routers.

believe it to be due to the necessary upkeep nature of a shop vac. if it is run with a clogged hose, dirty filter, completely filled bags/canisters it’ll experience excessive strain on the system. non normal working conditions if you will. low duty cycle + long run time + one of the mentioned items above =

whereas a router tends to work at normal conditions most of the time and is easily visible if something is a miss.

oh, and i was referring to the 3d prints by @MadHatter. sorry for the confusion.

Wouldn’t it be nice if that was sufficient!

“On many saws these days (my inexpensive Ryobi included) there is a shroud around the blade.” Safely is their primary intended purpose (though most users remove them), but they also somewhat control dust dispersion above the workpiece. Here’s a video on how to get it to do a better job, or buy a SharkGuard. More to the point here is - lower the Suckit brushes to the workpiece!

“They could see the dust-laden air moving towards every opening on the table saw.” I’ve blocked all of the unnecessary/counterproductive openings in my table saw and bandsaw cabinets. That improved dust collection considerably.

“Even more spectacular, when I had it, was the drum sander. That was dust cloud creator, but the same result. The air around the tool was evacuated, carrying the dust with it.” The higher airflows that dust collectors provide can help control dust cloud generation/dispersion when more efficient and effective techniques can’t be employed.

Your partial quote of my message misrepresents what I said.

I’m not here to argue with anyone.

Sorry if I misinterpreted and misrepresented what you said. I have no interest in arguing either - just trying to understand! ![]()

Like climate change, there’s arguments on both sides of that issue. Here’s one and here’s the other (which is likely significantly more scientific and credible IMO). I wonder how occupational health standards in other countries compare (hint-hint! @Julien,@others) For me it’s a no-brainer when unnecessary exposure to potential health risks is involved. I also don’t like waking up in the middle of the night coughing stuff up after a day at the shop.

I’m not trying to argue with you, but this really is a potentially serious health issue that people should know about.

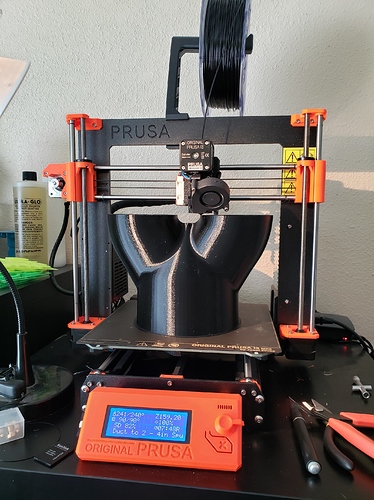

Here is the 6in to 4in Y adapter after approximately 38 hours of printing. Only 8-ish hours to go. Then I’ll print the 4in dust shoe. Once I get a functional design, it’ll get posted to thingiverse with all my other stuff.

I started the first print of this Wednesday evening (I believe) using a partial roll of black PETG filament. It ran out Thursday morning, and before I could tell my son to use the partial roll of white PETG setting out, he had already replaced the black PETG with black PLA. I couldn’t fault him - I have never used PETG for such a long print and I have told him to just replace the roll with the same color if it ever runs out when I am at work. So I waited until new rolls were delivered Friday before starting it again. On the upside, he now knows to look at the roll and see what the material is before replacing it.

So cool to see useful things printed instead of Cos play (yikes), dragons and Star Wars crap!

Hope the PLA substitution didn’t result in too big of a mess.

Yeah, I print a lot of crap, but I occasionally print functional stuff as well.

When I called my son and asked if the filament ran out, he hold me that it did about 30 minutes before I called. He told me what he did, and I told him about what was going on and told him to just hit the reset button and I’d deal with it when I got home. The PLA was printing just fine on the PETG. The hot end temp was above the print range for the PLA, but it was printing fine. You could barely tell where the line was between them.

Then I gave it a little flex, and the PLA ring at the top popped right off.

I normally print with Hatchbox / AMZ3D PLA filament interchangeably (they come from the same factory), but this is eSUN PETG. I am using eSUN because when I first went to buy PETG on Amazon, there was only eSUN available. And now I use it because it is a known quantity and it prints fine.

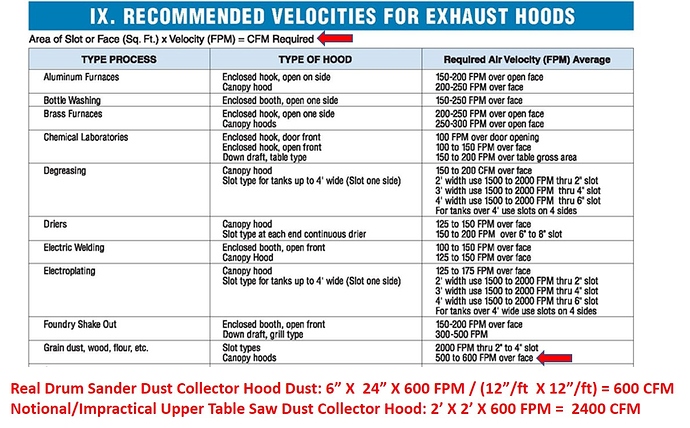

One of the more valuable links provided at Bill Pentz’s awesome and informative website is this one. It shows that, even if a 2’ X 2’ hood over the table saw could be oriented to effectively capture the dust produced above the table, it would take about 2400 CFM to do so. That’s the total capacity of our shop’s 7.5 HP dust collector. In contrast, a drum sander only requires about 600 CFM.

But, I’m now questioning the wisdom of having the height of the table saw blade set so that the blade’s upper gullets clear the top of the workpiece “to clear sawdust from the gullets”!

I run my table saw blade super low (only half the tooth height protruding above the workpiece) as to cut down on the amount of dust that gets shot over the top of the workpiece right into my chest and face. It helps considerably, but I am sure it contributes to me replacing them more often.