That’s what I intend to do from now on too. I can’t see how it would negatively impact blade life though. As I pointed out here, “a typical 10-inch combination blade for a table or miter saw has 40 teeth and spins at 3450 RPM. A 100 IPM feed rate produces a 100/3450/40 = 0.0007 IPT chipload.” So dust buildup in the gullets seems really unlikely. An added benefit is that the negative impact of an imperfectly aligned rip fence would be mitigated somewhat because less of the blade’s cross-section is involved in the cutting process.

P.S. I’ve learned that getting saw blades sharpened is quite cost effective.

I have never bothered to look into it with the life I’m getting out of cheap blades, but I am also far from a “fine” woodworker that runs $150+ saw blades. How much does it usually cost you?

Laguna charges $45 to sharpen their ~$200 carbide Resaw King Bandsaw blades. I’m not sure about any others, but I’ll ask around when I get the chance (if I remember).

Forrest charges $22-$37 to sharpen table saw blades, depends upon number of teeth. You also have to factor in round trip shipping.

They will also repair/replace teeth, additional cost.

IMO Forrest blades stay sharp longer and yield glue-ready, zero tear out cuts.

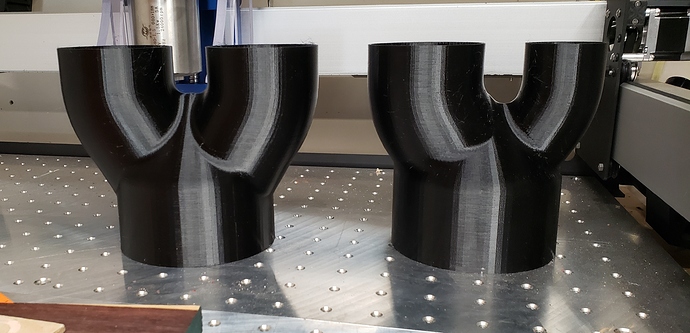

After 45 hours and 45 minutes, the 6in to two 4in adapter is done (on the left) and for comparison, the 6in to 4in and 2.5in adapter is on the right.

Everything fits just fine, so I’ll be putting it on thingiverse here with all of the other adapters I have.

EDIT: I just tried uploading them to Thingiverse, but it is not allowing me to upload them (it’s broken again/still).

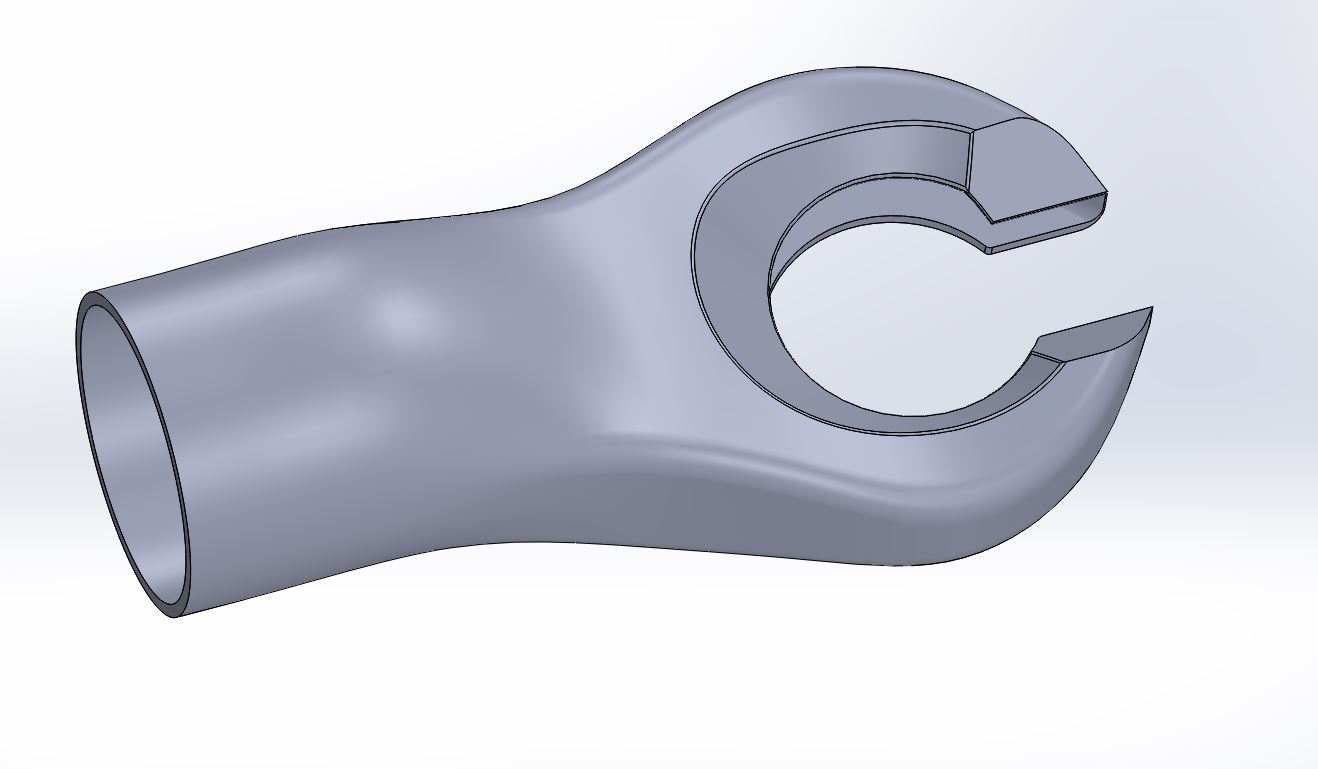

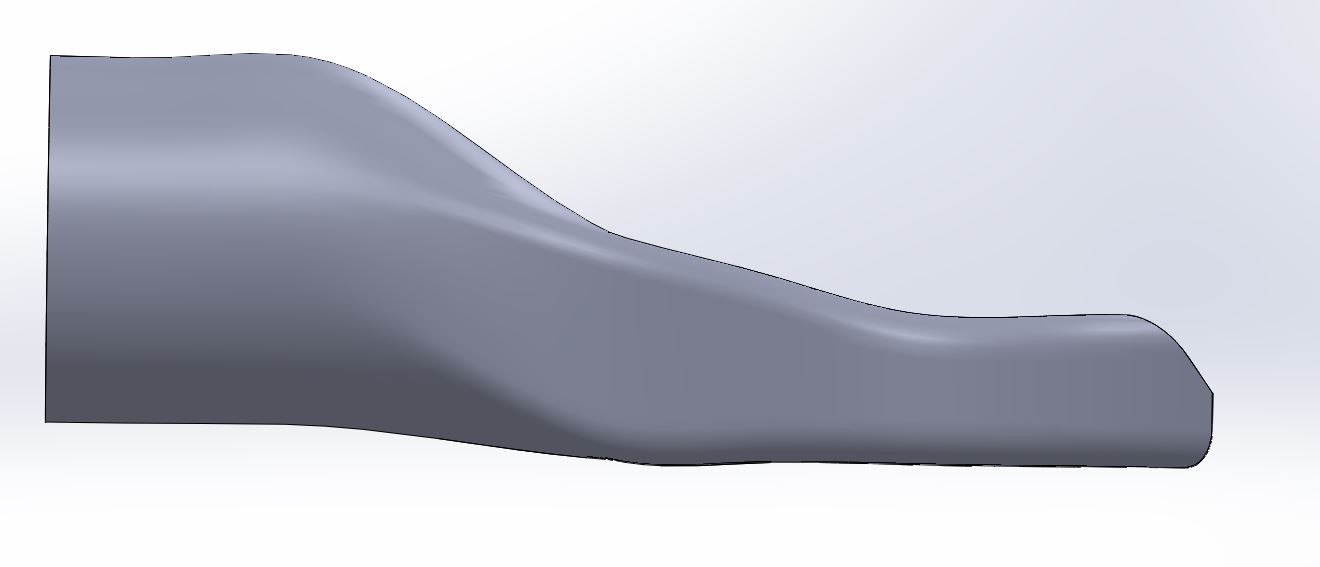

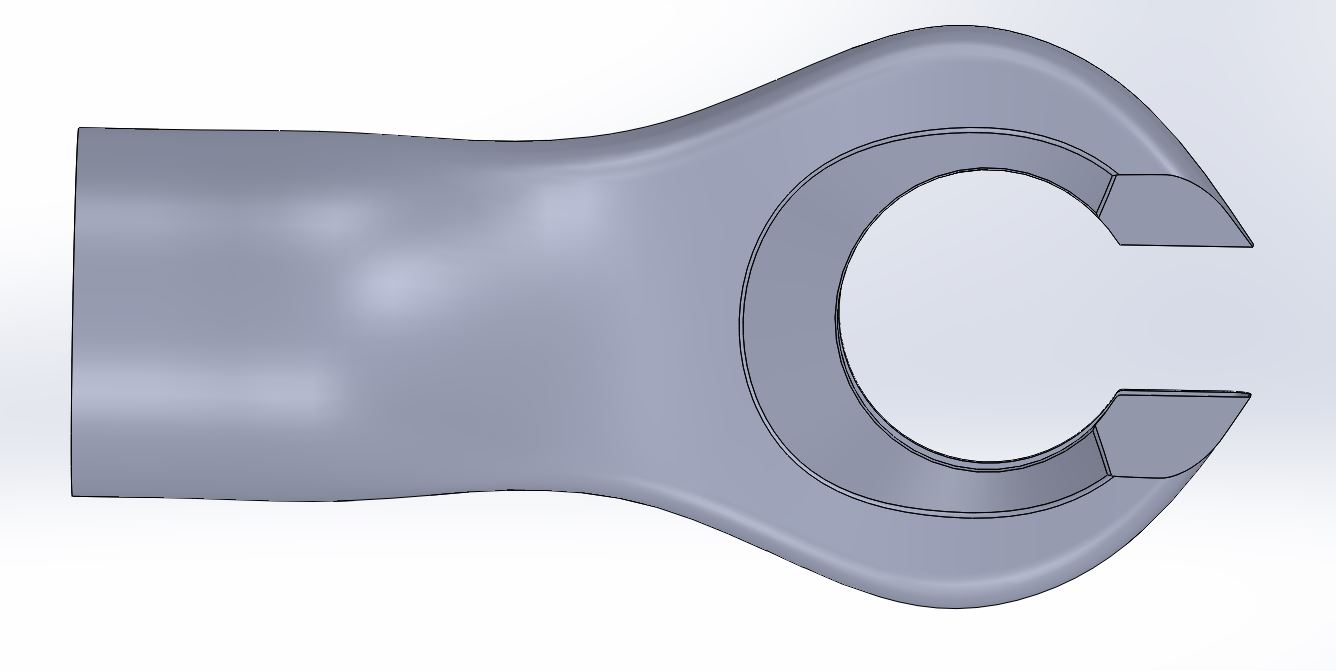

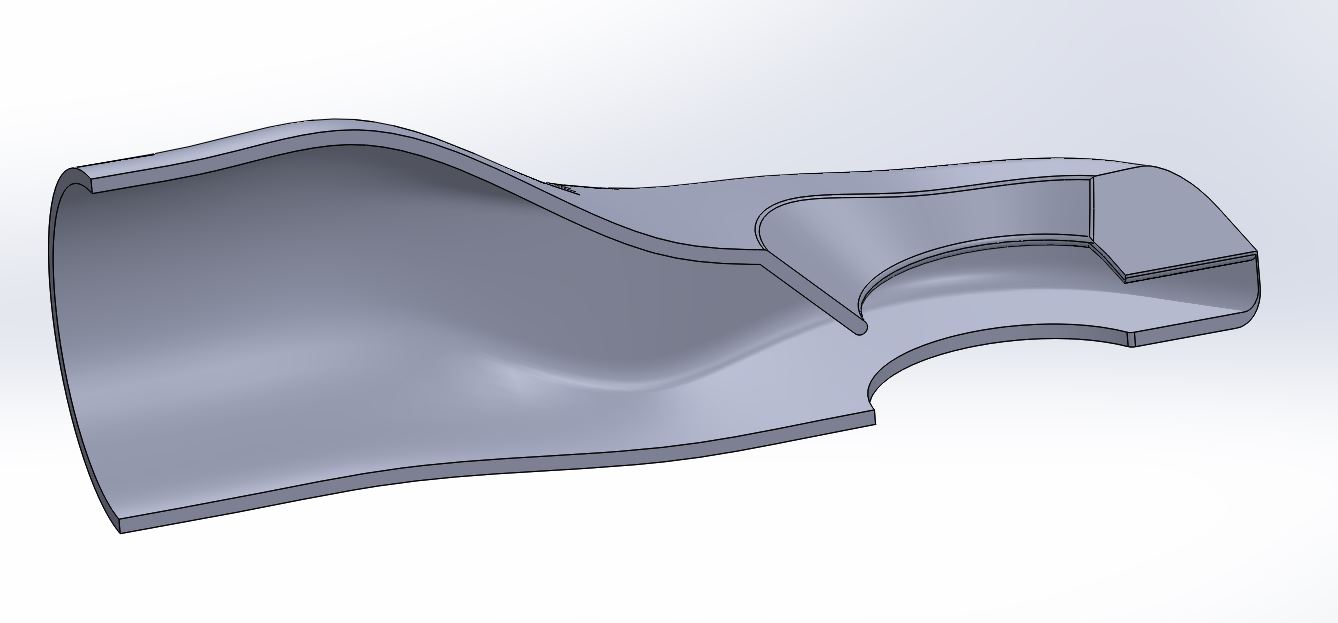

Also, since I can’t seem to stop designing things (whether they are actually needed or not) here is something that will allow me to watch as very small engravings are cut while still sucking up the dust (hopefully). It is made to fit on a 2.5in flex hose. I have the hose end sitting 0.2in higher than the cut out area so that there is room for the flex hose and hose clamp and still allow the flat part to sit on the work piece.

I’ve heard that they do a really good job too!

Awesome! Let us know how they work!

The only valid arguments on climate change are the ones which show that it is happening.

All the arguments against are specious, seizing upon tiny inconsistencies in the data / modeling which has continually improved, and become more accurate as our understanding becomes better.

It comes down to 3 basic facts:

- CO2 is a greenhouse gas — this has been known since the 18th century and can be demonstrated by experiment quite easily

- burning fossil fuels releases CO which bonds with oxygen to make CO2 — anyone who doesn’t believe that is invited to test their disbelief by idling a vehicle in an enclosed garage

- the added CO2 results in the planet either absorbing the CO2 in unanticipated ways (the ocean in particular has absorbed a lot more than early climate models predicted), or heating the planet

Unless one can come up with a plain and logical explanation for what the CO2 is doing which will not ultimately result in the planet increasing its absorption of solar energy or what said energy is doing besides heating up the planet, one doesn’t have a valid argument against the brutal reality of climate change.

Yup! Yet nonsensical arguments against it persist nevertheless (and even seem to be gaining traction!) I guess that’s what happens when facts no longer matter! ![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.