Hello I am working on what I should be expecting from a machine like the shapeoko five pro. I am working hard to learn, carbide create, and it’s coming along fairly well.

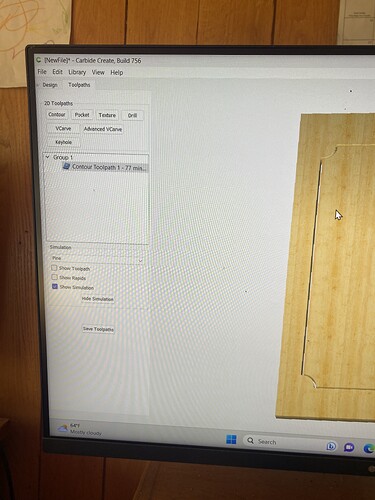

My question is does 77 minutes to cut a 18” x 18” square with filet corners out of 1 inch thick Pine seem about right or do I have Settings wrong and can speed that up?

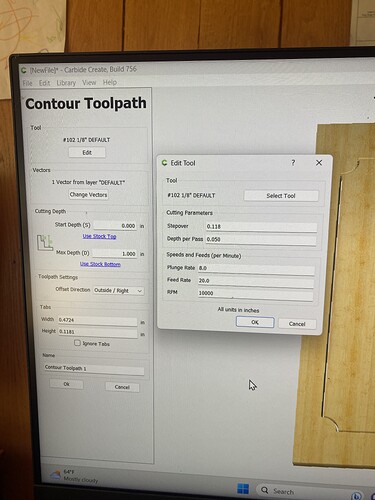

Below are the settings I have set I’m not 100% sure how to tell if it calculated the proper type of material or not.

do you need to use an 1/8" bit? 1" is pretty deep for one and the default settings are usually quite conservative which is reflecting in your estimated time. If you can up that to a 1/4" bit you can easily double your depth per cut as well as maybe up your feed rate to 80 ipm to start. With pine you might have some tear out as well so be prepared for that.

I’m having trouble understanding how the bigger bit can go quicker as it’s cutting twice the material out?

Oh my God the time dropped to 17 minutes with a quarter inch bit!!!

It’s more rigid and can move faster with less likelihood of breaking.

Also, the #102 1/8" DEFAULT tool is quite slow/conservative.

What material are you cutting?

Lastly, how deeply are you cutting? If deeper than the diameter of the endmill, add offset geometry and cut as a pocket down to tab height or the penultimate pass.

I still have not cut anything, because I don’t understand the program fully yet, but the woods I will be using as I live in the north east will be Pines Oaks, and Cherry mostly.

Do most people use the quarter inch bit for general material removal being faster?

And only use the smaller diameter bits for details?

exactly yeah, 1/4" bits are easily my most used bits.

but it all depends what you will be making

Thank you for the explanation @Dooryard

Knowledge is power!

everyone here is very helpful and friendly, I just happened to catch your question, try some stuff, ask questions, imo its the best way to learn. best of luck!

Okay, I got to a 78 min. toolpath by cutting around the perimeter of a 30" x 30" square to a depth of 0.625" using the #102 1/8" DEFAULT tool setting.

Changing that to Hardwood reduced it to 56 minutes, and Softwood 28 minutes.

I use a #102 quite a bit (well, a 1/8" downcut, c.f., the Amana #46200-K .125" 2 flute down-cut which we sell).

My suggestion is to not use the #102 1/8" DEFAULT feeds and speeds, experiment in some scrap at first, start w/ the larger 1/4" tool, and work your way down to 1/8" tooling once you have a feel for how a good cut sounds.

Also, avoid slotting.

Where possible avoid slotting and add geometry and cut as a pocket

and/or

and consider leaving a roughing clearance and taking a finishing pass.

This topic was automatically closed after 30 days. New replies are no longer allowed.