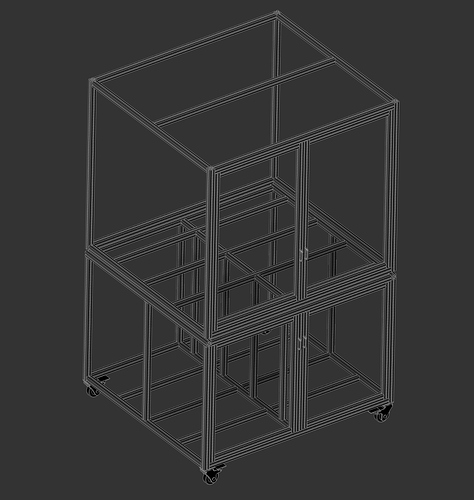

The horizontal slats will coincide with the Pro frame, I settled on 52"x58" inside diameter 48" high. This will enable me to use a 2.5 vac comfortably around the machine, which I did not allow for on my last enclosure. Alu-Poly panels with clear acrylic on the upper front doors and back panel. Top will sit on 3/4 ply with .125 stainless plate on top.

Sorry for the off topic question, but I’m new to 8020. I’ve seen it around but actually didn’t know that is what they call it and that it had such a huge fan base until I started reading this forum.

Why do you go with 8020 vs wood? Precision, lightweight, Cheaper, Comfort? Just wondering whether I should start leveraging it in my own builds?

Also, who do you typically buy it from?

Primarily it’s stiff, looks clean, and has attachments to go together nicely. Personally I like buying pre-cut and drilled pieces from Misumi. There are a lot of aluminum extrusion t-slot options available, some branded and some Chinese versions. For the most part they will all get the job done unless you are building something like motion components (CNC Mill or printer) and then you probably want to get the real deal.

McMaster-Carr, 8020.net, Ebay are some resources I’ve used.

There are also different ways to attach it together, corner cubes, you can drill it out and bolt directly through another piece, or you can just use plates on the outside surfaces. All depends on how much you want to spend, if you want to modify the extrusions, and the look you are going for. It is not going to be cheaper than wood.

This 80/20 Pro enclosure will probably cost around 4500+ including casters and hardware. Much easier to put together then wood, stronger, no warped pieces to deal with and is also easy to configure, add on to, and disassemble.

Things to consider the hardware and aluminum extrusions are very expensive, 30 day or more wait for your order to go through, and high shipping costs.

I recently over-built a very sturdy bottom cabinet out of 4x4’s with premium materials, with 3/4" plywood covered in white marker board Formica, and it was about half as expensive as the 80/20, 10 times more work and was very frustrating dealing with warped wood, trying to get things level and straight.

I will stick with the 80/20 from now on, very expensive, but it makes more sense to me. Can have this whole cabinet assembled in 10 hours solo. I spent about that much time just drilling pilot holes for all my lag bolts in the 4x4’s…

Dust and sound containment are a must for my situation so the expense is necessary.

Dang son, that setup is just WOW. Now I remember your earlier post with a screen mounted behind the enclosure, but 3 is going to look very pro. Do you find independent dust collection is necessary, or just how things have evolved? Making an assumption based on the multiple cyclones in your render.

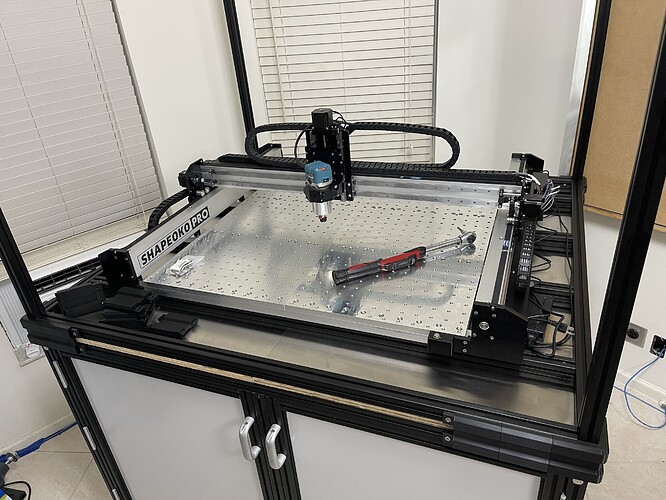

Each machine gets a Cyclone and a Rigid 200 CFM shop vac and one of my 3d printed hose sets. Also a network of air blast hookups, and water cooling for spindles. Rear monitors on all enclosures running on mounted Microsoft Surface Pro 7 i5 8gb tablets. with tech keys key pads.I am making progress daily should have things assembled and ready to start using in a few months. Need some large metric measuring devices to plot out the bolt hole spacing on the Pro frame, is holding up my design. Might have to get inventive with a 6 inch caliper and some tape ha ha…

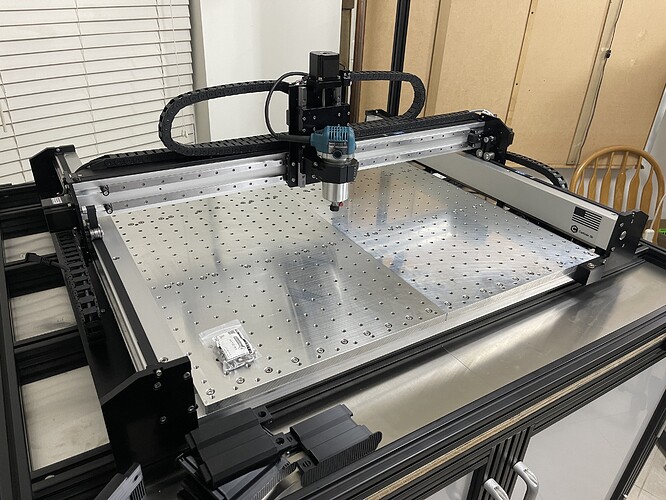

80/20 has finally delivered my extrusion. Using 20 gauge brushed 304 on 3/4 Red Oak ply for a deck surface.

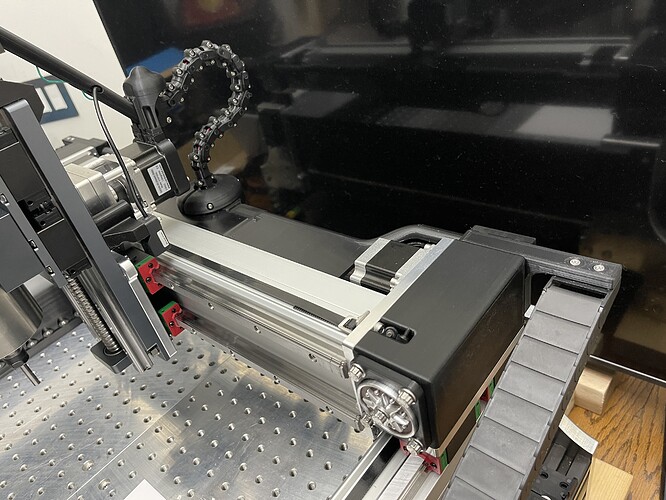

I definitely need to design some pulley covers and wire covers for the Pro before I enclose the machine. I am also considering upgrading the y rails and carriages on this machine to Hiwin HG15 and design some thicker mounting plates. My X rail is smooth and perfect but my Y rails on the Pro are all screwed up. I can feel the carriage bearings bumping vertically as it moves in a certain area on the rail but not others. I can’t feel any warp in the rail channel though.

My eyecrometer is poor… did you go HG15 on your SO3, what is making you lean towards the bump in size?

Awesome work as always, Max!

Yes the S3 has 15’s they are very nice. Was thinking the Pro would benefit from the upgrade…

Are those the stock linear bearing blocks on your Shapeoko? Mine are all black, have no lubrication port, and increasingly binding up after doing some simple MDF and wood parts (with dust collection). I am wondering if Carbide3D changed them to resolve that issue, and just sent support an email.

Edit: never mind, I see your reply that you are just considering to upgrade to Hiwin HG15s and it is not a Shapeoko Pro.