Thanks! Looking forward to folks trying this out — I think the larger tool simplifies things sufficiently that it should be straight-forward for folks to cut.

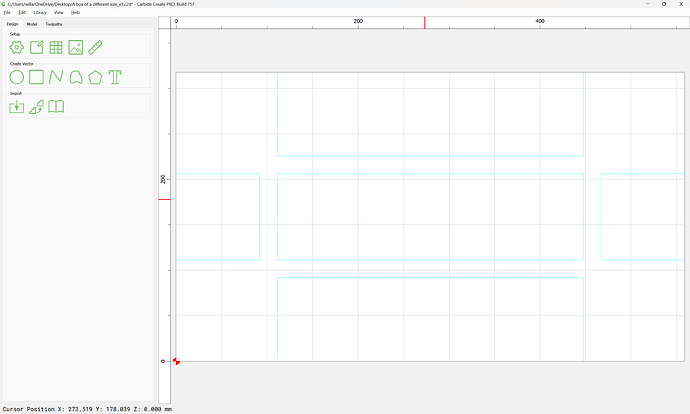

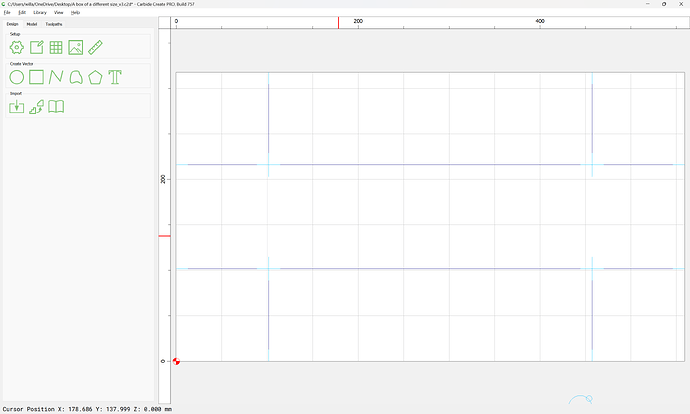

Adjust the inset geometry for the initial V carving to be at diameter:

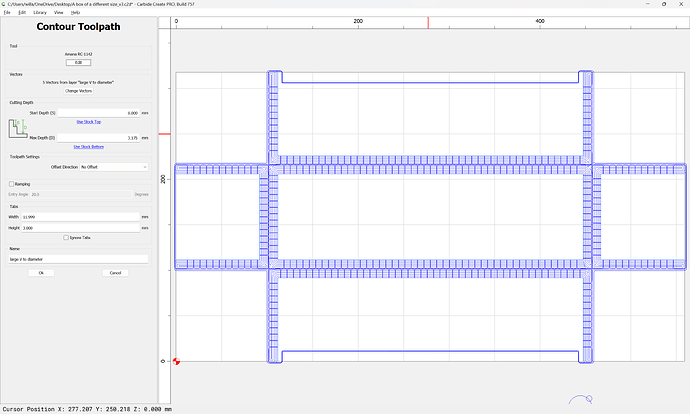

and the toolpath to match:

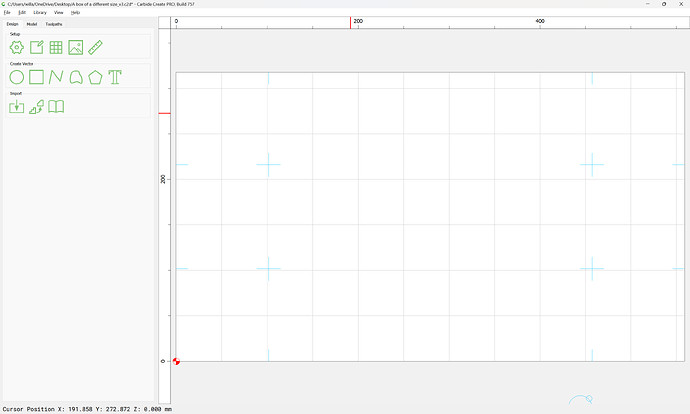

Adjust the open geometry for the full-depth V carving to project stock thickness from the corners:

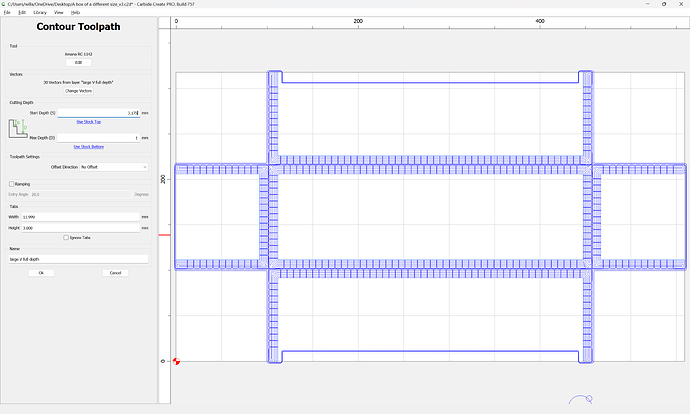

and adjust the toolpaths to match:

(a further optimization would be to determine how low the tool can be lowered before coming into contact with the sides of the channel)

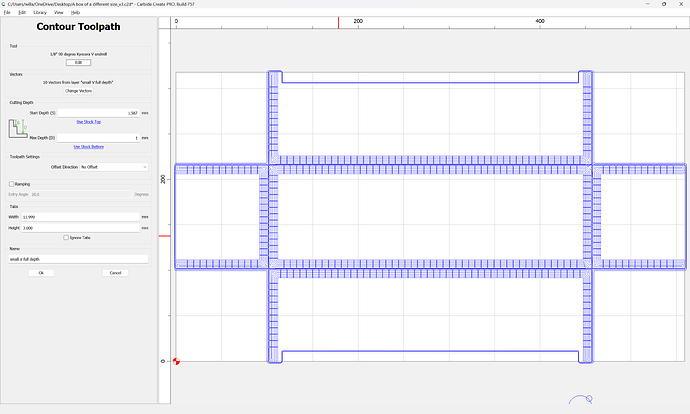

For the small V to full depth geometry, it should reduce time to only cut in-between the full-depth V passes w/ the large tool:

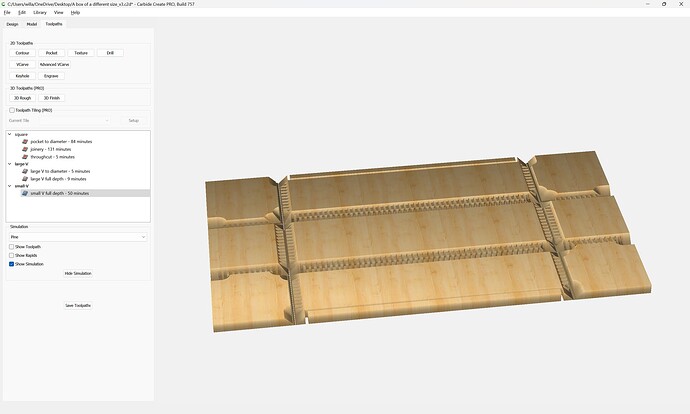

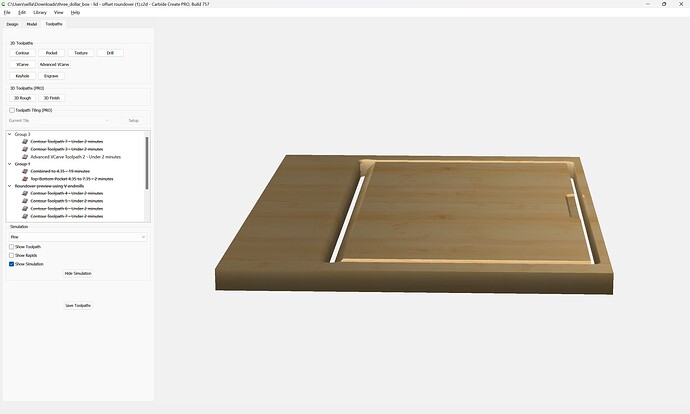

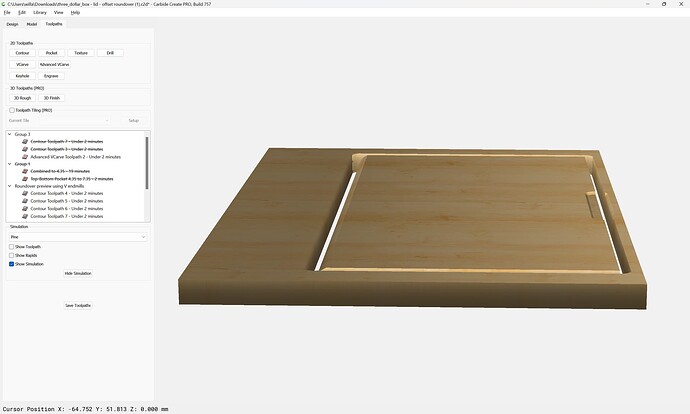

which all previews as expected:

and the box should be done:

A box of a different size_v3.c2d (212 KB)

Note that for such joinery, esp. if cut in that orientation it may be necessary to calibrate for belt stretch:

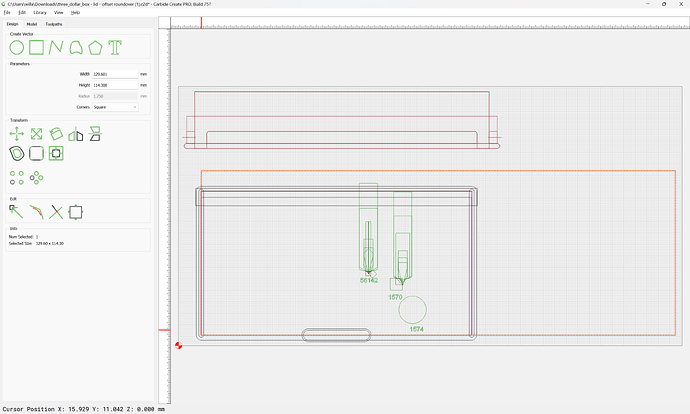

Last is the lid:

which we will do in a modified version of the previous file.

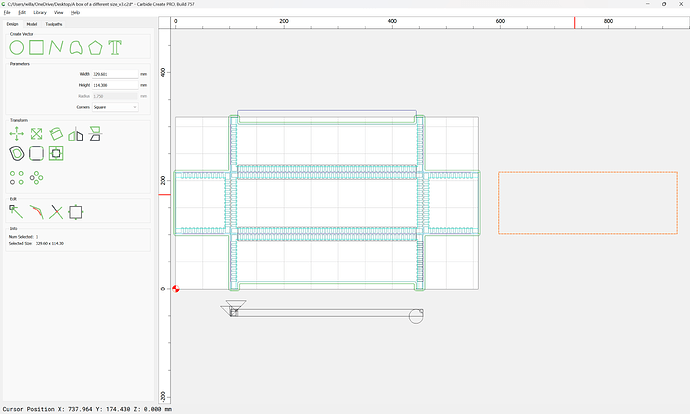

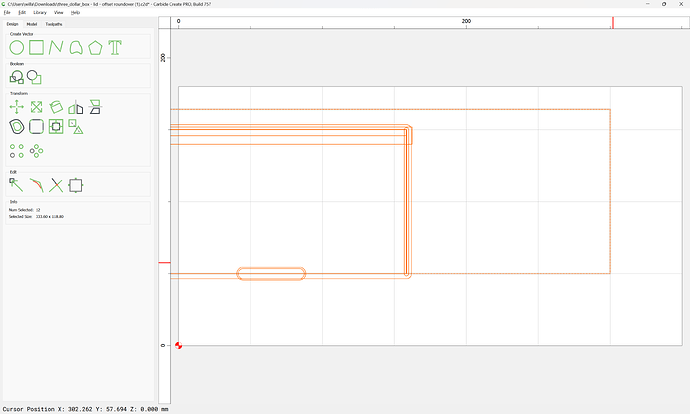

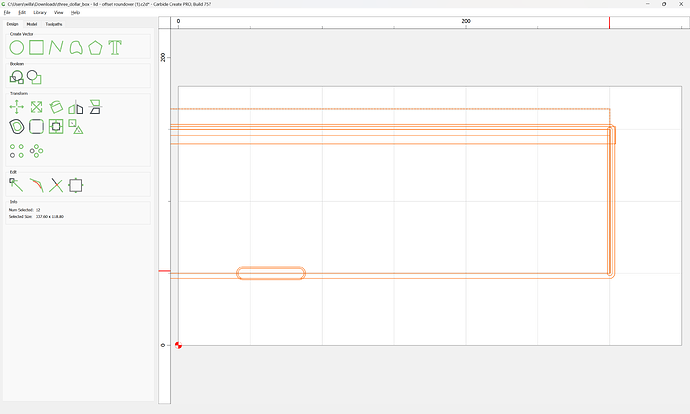

As opened, the file in question is ready for cutting:

as discussed at the previous link:

roundover tooling cannot be directly previewed in the current version of Carbide Create, but can be approximated with several V endmill passes:

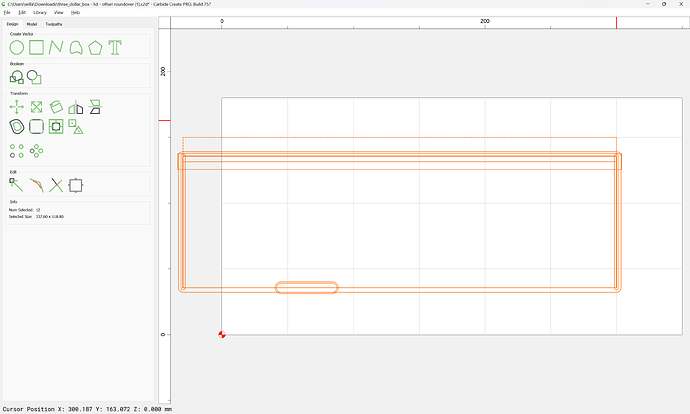

Modifying this file requires changing X and Y to match the dimensions of:

which brings up an interesting way to change the dimensions of a file (using this technique to change the balance of the files for the box is left as an exercise for the reader).

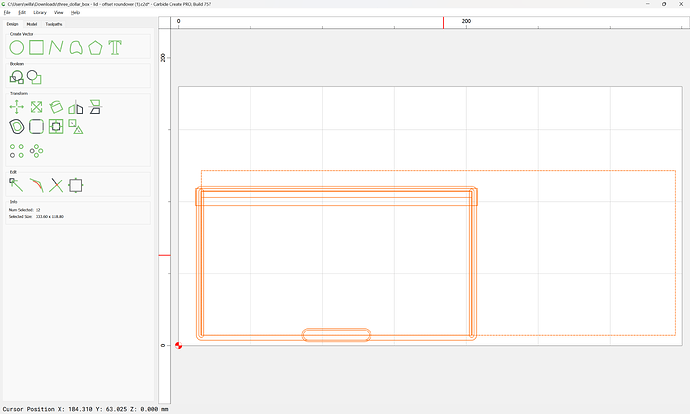

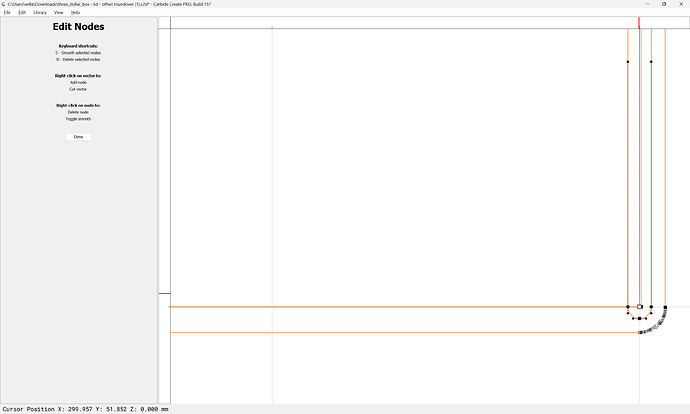

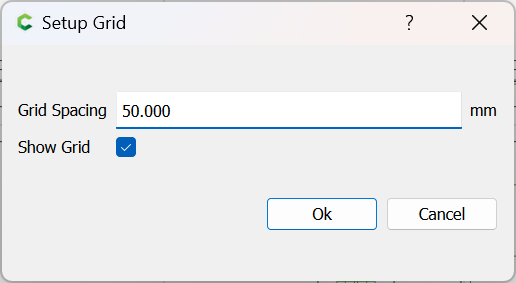

First, set the grid spacing to a very coarse dimension:

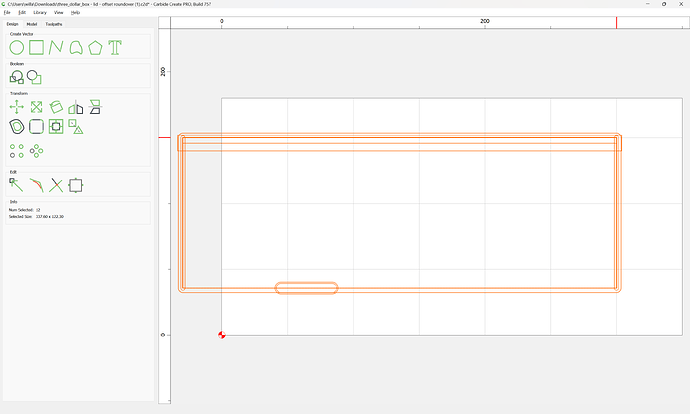

Then select all the elements which one wishes to adjust, including an element which is the desired dimension:

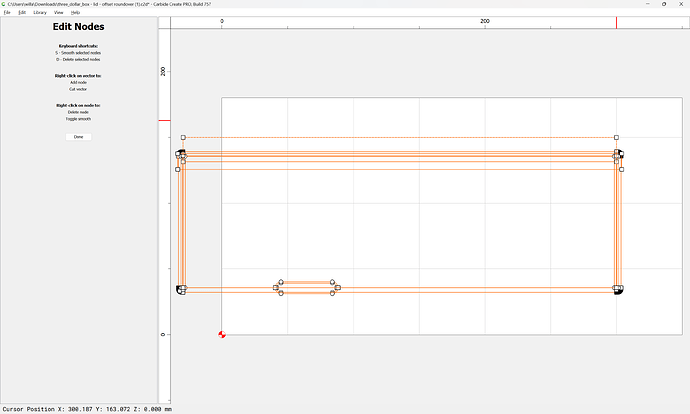

then drag it until one point is at a grid intersection:

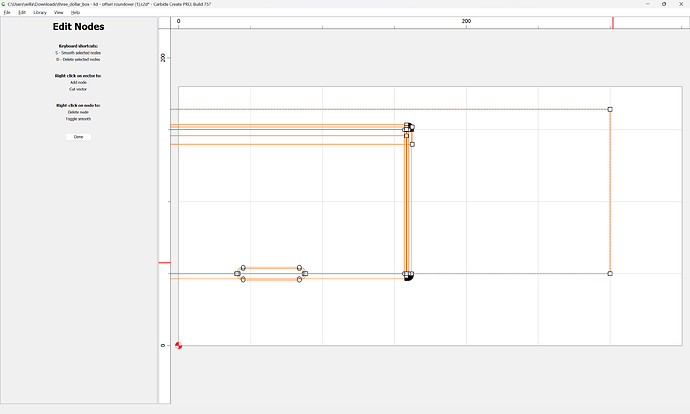

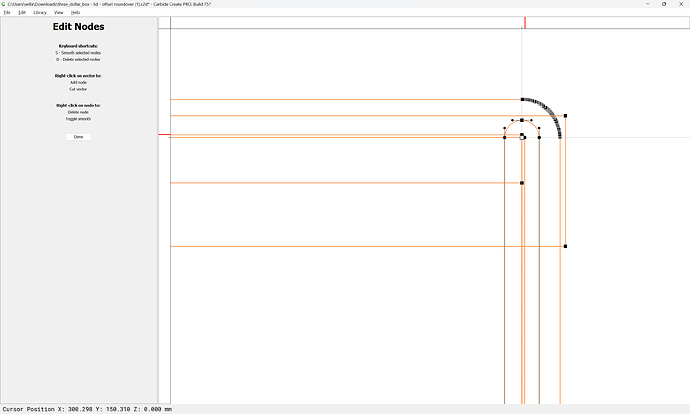

Go into Node Edit mode:

Select one entire edge of the design which includes the point which one wants to move to the desired dimension:

begin dragging to the grid intersection:

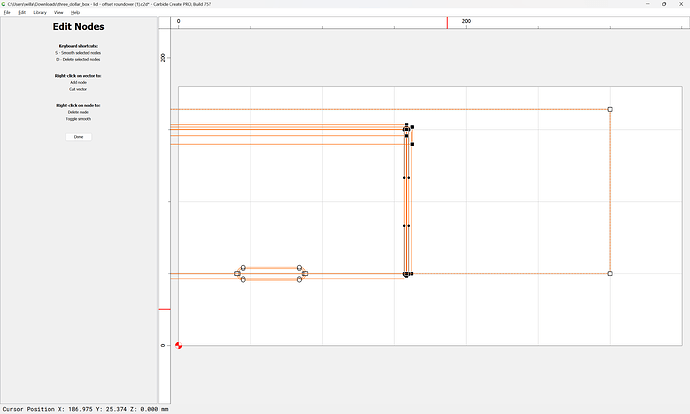

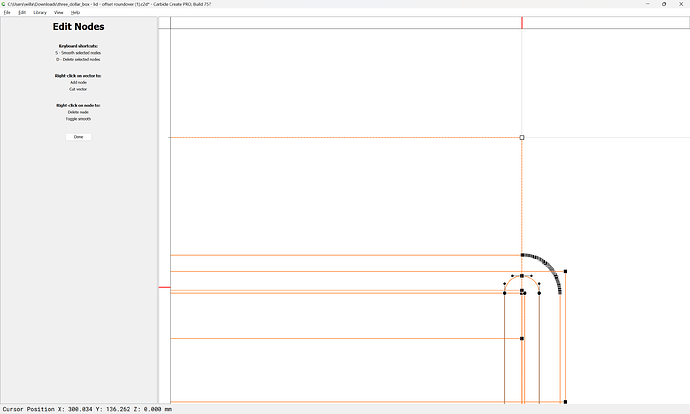

Done

repeat for the other edge:

Done

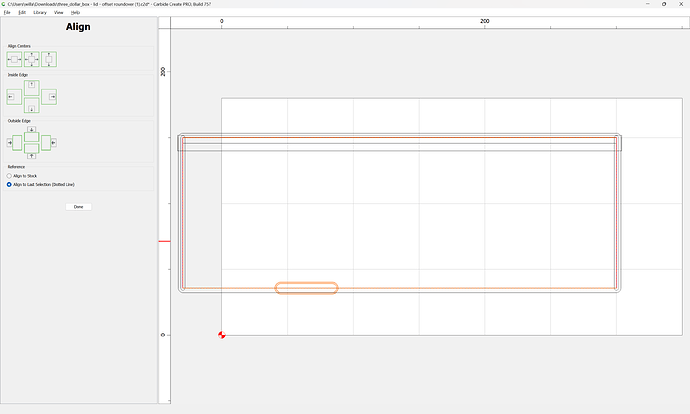

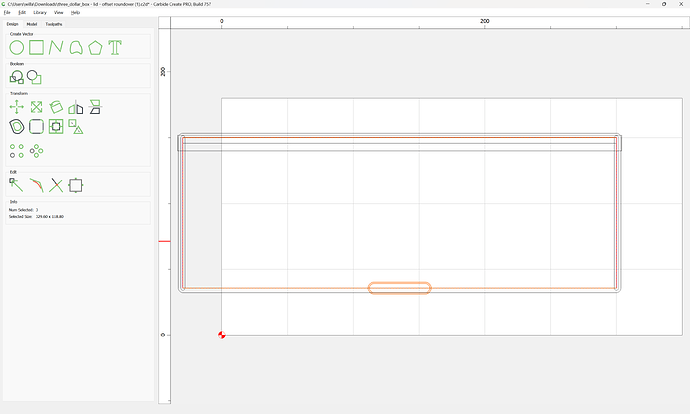

Select any elements which need to be adjusted and align as necessary:

Note that the thickness will need to be adjusted, and the 1572 tool defined, and the fixture similarly adjusted (didn’t think to include it in the selection, mea culpa).

As I follow along with this build on my computer I can’t help but being impressed on the creative nature of the joinery design. I would have never thought to use Linear Array in the box joint design. My approach would have probably been with a single element design then Duplicate and Align. Great tutorial with many lessons learned.

I wish I could take credit for it — a number of folks have done this sort of joinery before I finally settled upon it:

I’ve got an idea for a perfect joint, but I’m still working on the math for it — if anyone has any books on conic sections to recommend, I’d be grateful.

This topic was automatically closed after 30 days. New replies are no longer allowed.