WillAdams

April 3, 2022, 2:27pm

1

These are usually used in routers for decorative effects in wood:

https://www.whitesiderouterbits.com/products/1570

but they are potentially useful for joinery:

Next up is more boxes, this time for magazine storage — for my part I just cut open Fed Ex boxes:

[WIN_20190912_14_02_59_Pro]

But they’re not always available in a suitable size for typical magazines.

There are a number of commercial options:

So there is certainly precedent for wooden boxes — we’ll try for an inexpensive material, since this is going to be a fairly large project (sorry Nomad owners) — Luan Plywood is available at most home centers, usually as underlayment, a bit of care…

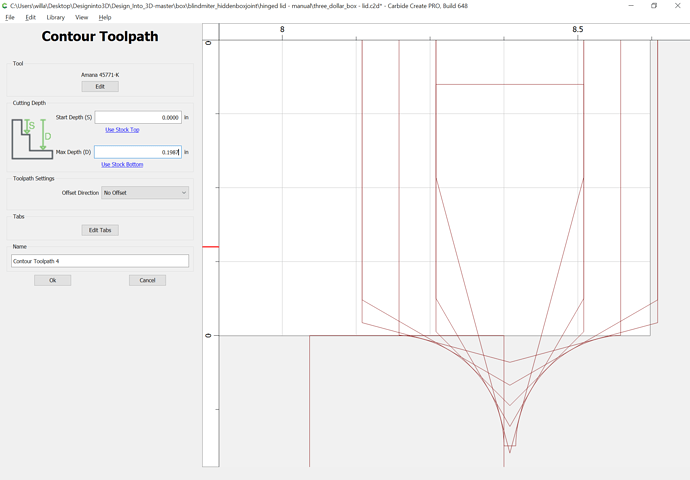

They are also useful for rounding off parts to allow rotary motion as for a hinged lid.

Unfortunately, Carbide Create does not support this endmill geometry — but using the new support for previewing a V endmill when used in a No Offset Contour toolpath, it should be possible to preview them w/ confidence by stacking a series of V endmill cuts.

2 Likes

WillAdams

April 3, 2022, 3:59pm

2

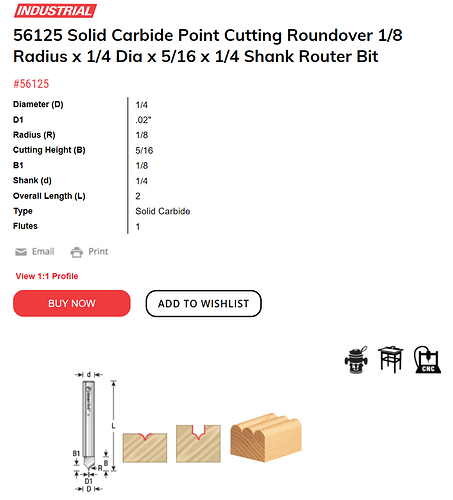

Another source for these is Amana:

Industrial Quality Router Bits, CNC Router Bits, Saw Blades, Shaper Cutters, Boring Bits & Planer and Jointer Knives by Amana Tool

which has the advantage of providing rather more detailed information, in particular the tip diameter:

which allows one to set up a tool w/o the need for a test cut.

I was looking at these the other day and with a simple properly spaced grid could make for a nice soft “pillowy” background effect. like a nice tray of milk buns or somehting

2 Likes

WillAdams

April 3, 2022, 5:23pm

4

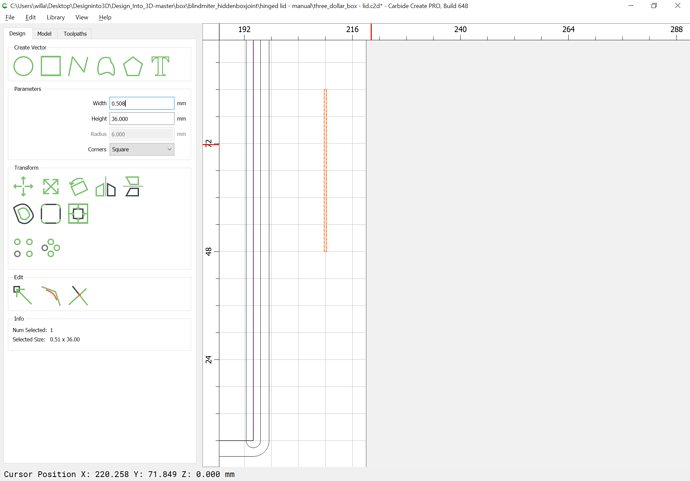

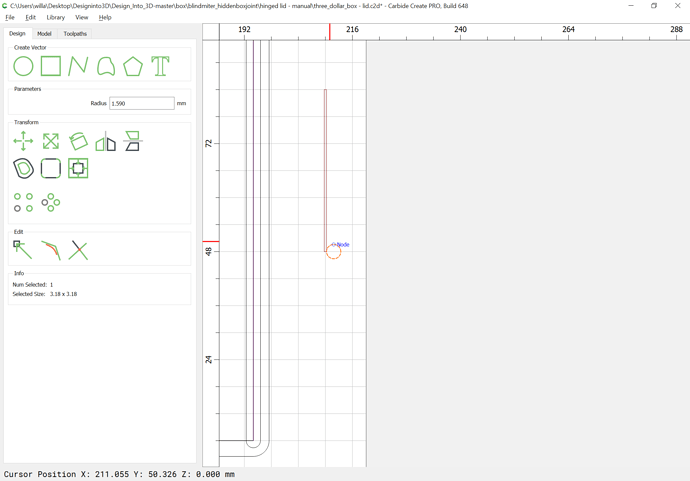

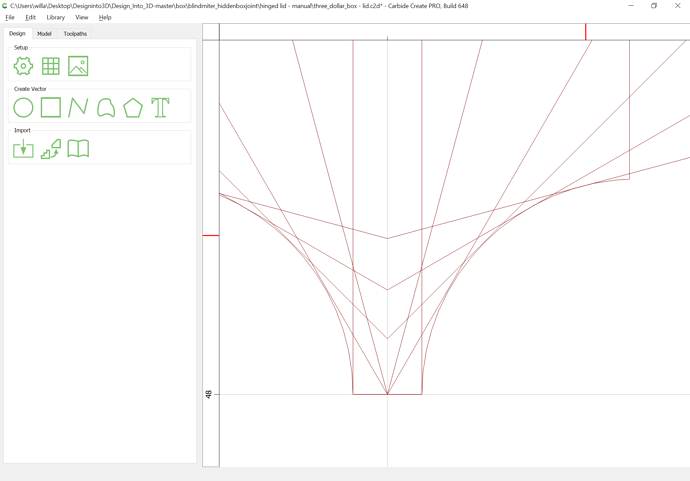

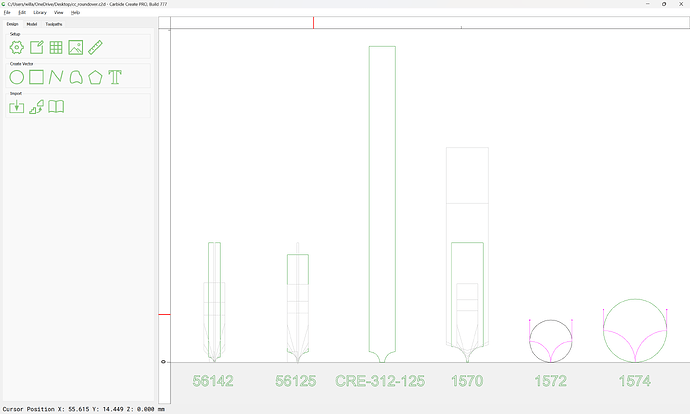

To get a preview of how the tool will cut, draw up such a tool in profile (or import the DXFs):

The tool drawn above is:

With a profile in place, it is simply a matter of matching up various V endmills at appropriate depths:

(depicted are 30, 60, 90, 120, and 150 degrees)

This also brings up the fact that one could make such cuts using a series of V endmill and then sand to the desired profile.

WillAdams

April 4, 2022, 3:36am

5

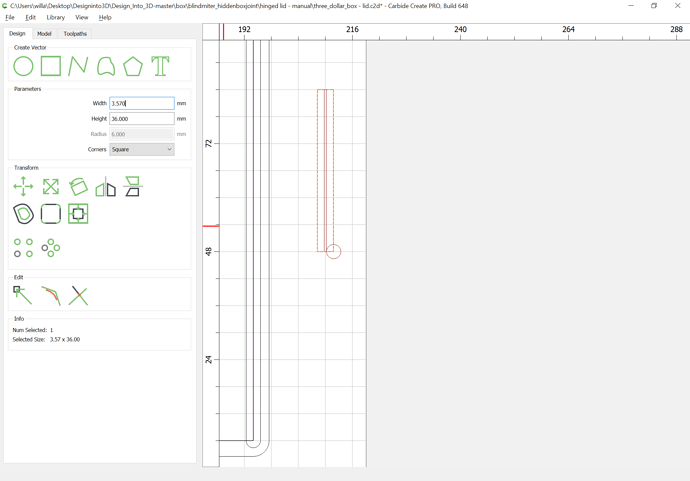

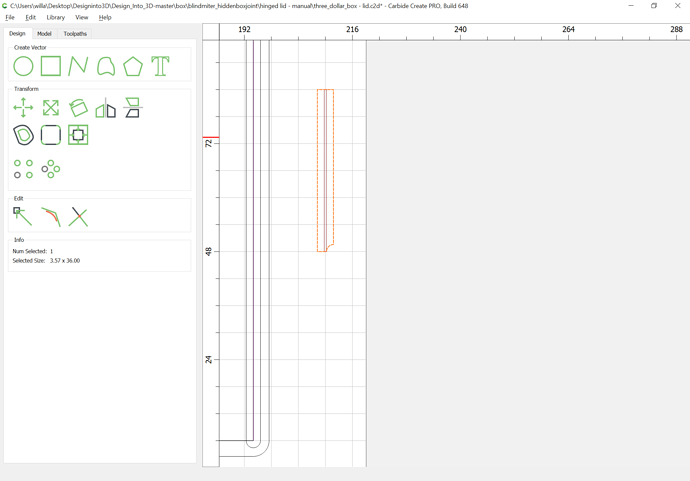

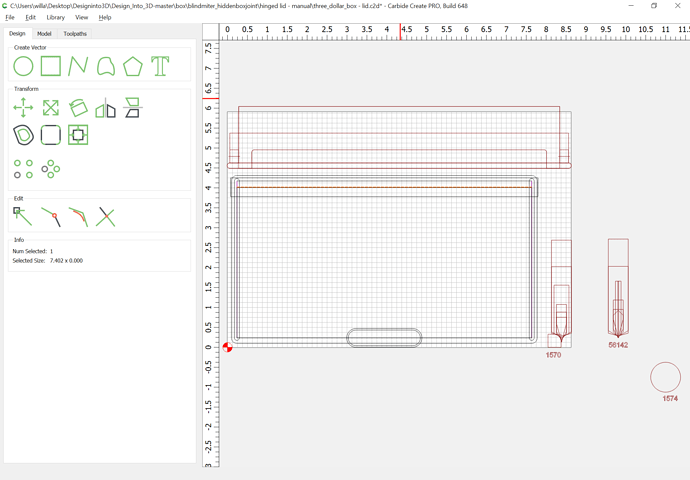

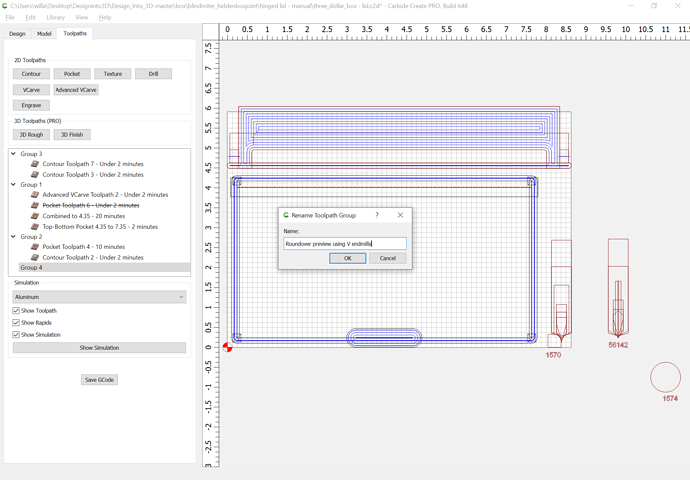

Once the geometry which we wish to use is drawn up:

we position various V endmills relative to it:

and then draw the line for the contour toolpaths:

and create a group for the V endmill toolpaths:

and then assign the various V endmill toolpaths cutting to the appropriate depths:

until one arrives at:

1 Like

WillAdams

April 29, 2022, 2:22am

6

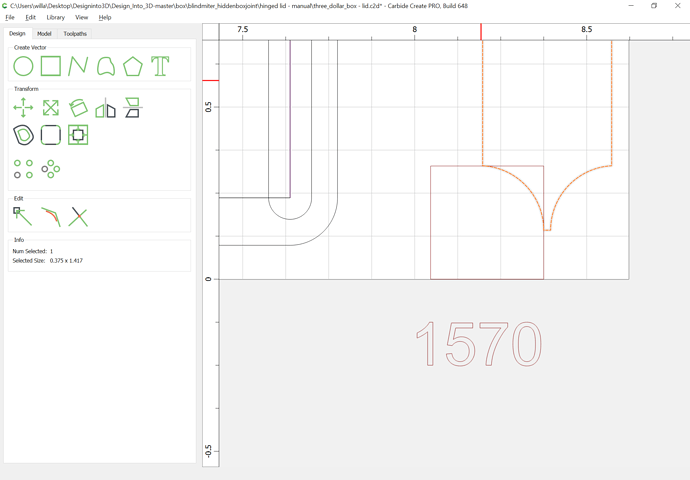

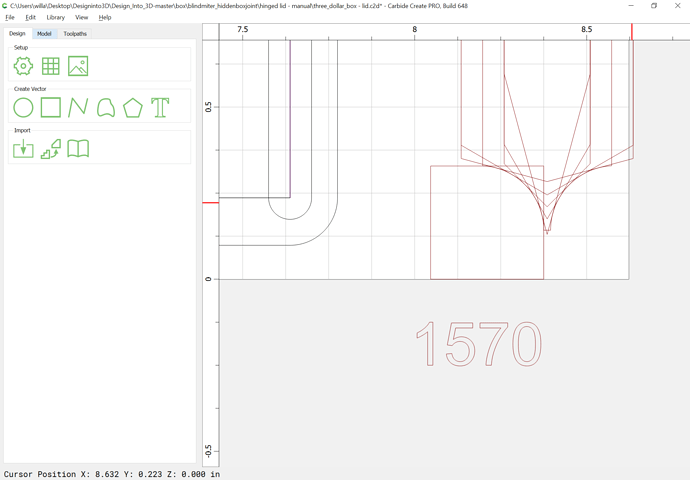

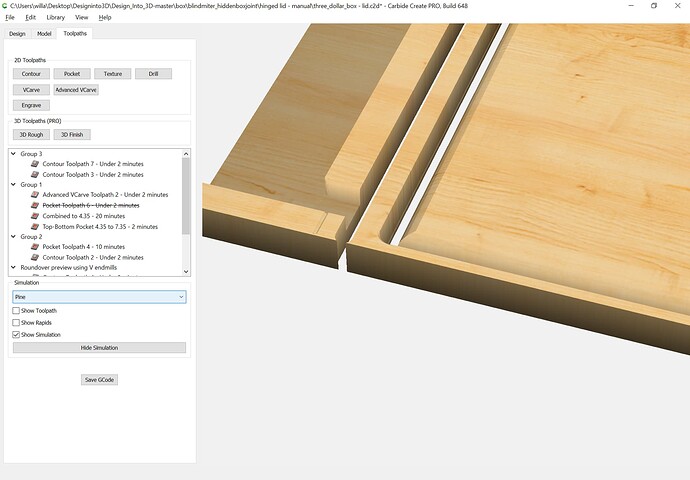

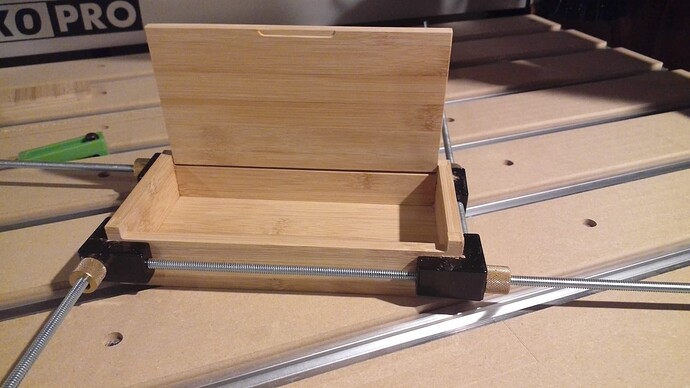

Here’s a lid which uses this technique:

three_dollar_box - lid - offset roundover.c2d (501.2 KB)

which can be used on:

Revisiting

for a hinged design — first, verify the concept by designing and cutting a prototype in Carbide Create, then going back and updating the 3D modeling.

First consideration is size — want it to use 3 bamboo cutting boards:

top

bottom

sides and front and back

[image]

1 Like

WillAdams

April 29, 2022, 11:51am

7

2 posts were merged into an existing topic: Clamps and clamping techniques

WillAdams

April 29, 2022, 12:21pm

8

The fit and appearance of the lid w/ the roundover tooling is much better:

system

May 3, 2022, 2:27pm

9

This topic was automatically closed after 30 days. New replies are no longer allowed.

system

June 13, 2024, 11:40am

11

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.

WillAdams

June 28, 2024, 2:02am

12

Here is a set of roundover tools:

cc_roundover.c2d (240 KB)

1 Like