as requested on support…

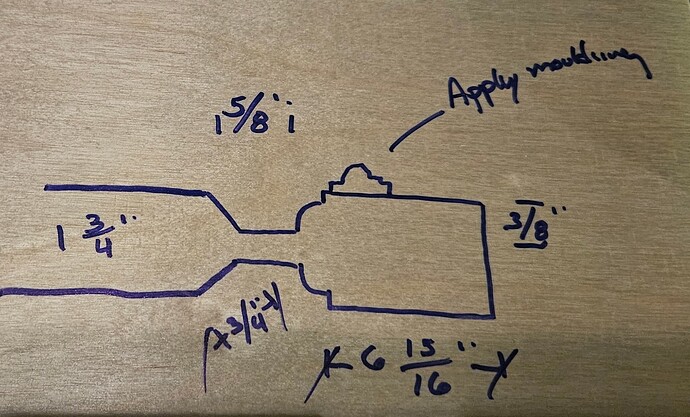

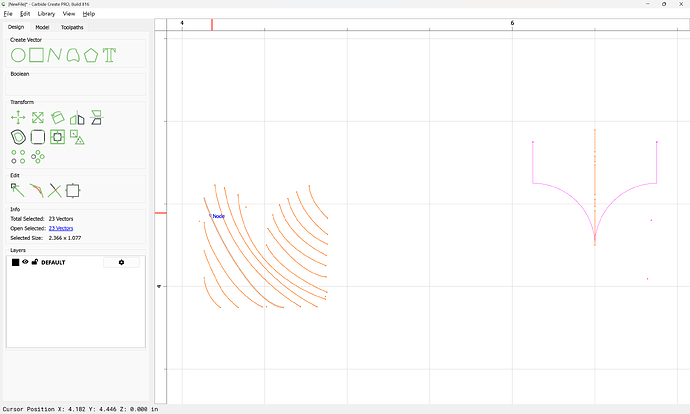

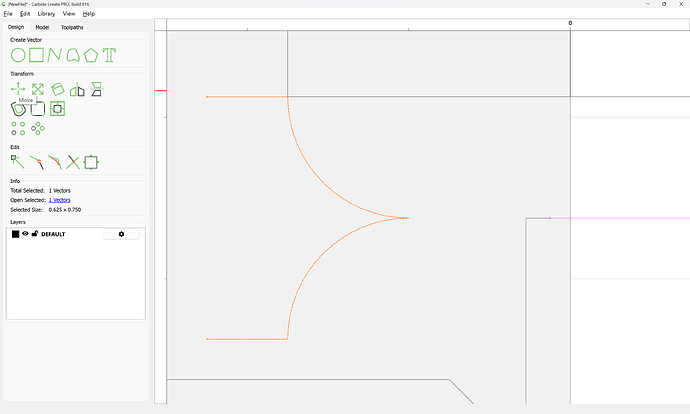

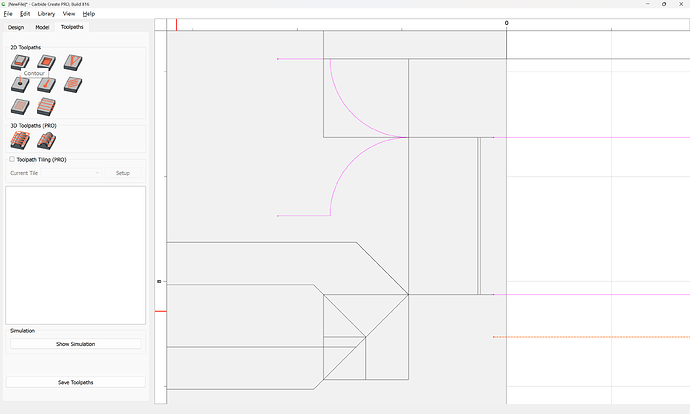

given the typical sketch:

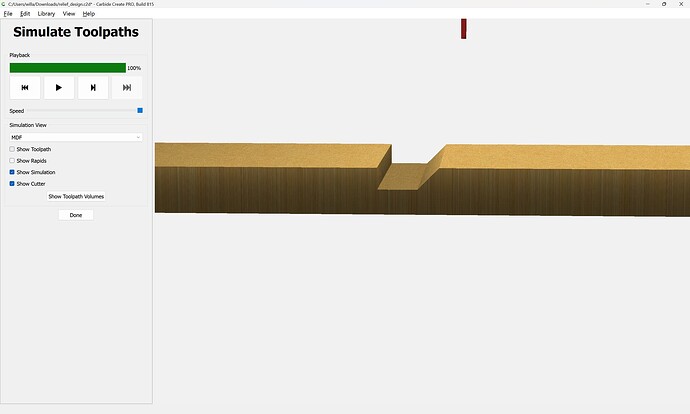

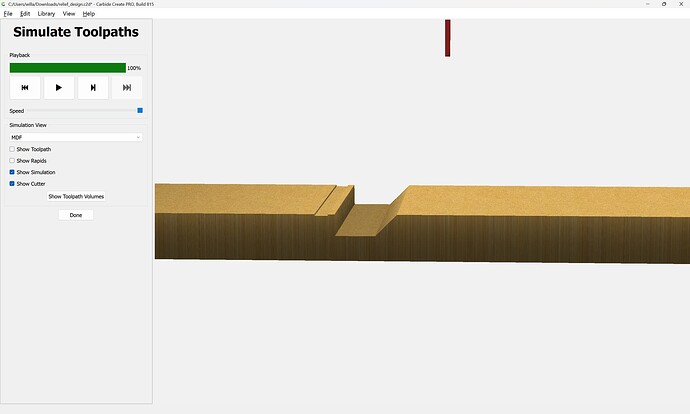

We need to work out how to cut that as a profile into a piece of suitable material (which is 1.75" thick).

This will require:

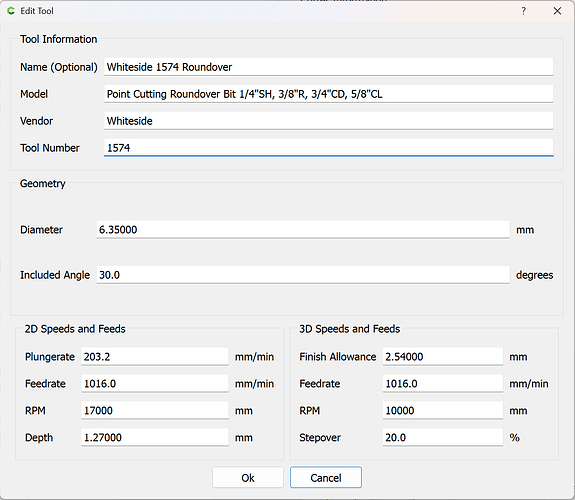

presumably a 1574 (folks w/ an ER-20 spindle should consider the 1580)

The other consideration is the size of the stock — I am going to assume that this is going to be cut into glued up MDF and that the length will be 4 ft — presumably the CNC is being used to avoid the expense of having a set of molding knives made, or doing multiple setups on a routing table or shaper (cue old joke about a shaper — it’ll make anything but money (due to the expense of tooling and the time and effort of setup/operation)) and only a short length is needed (perhaps it’s part of a door?) which avoids the need for tiling.

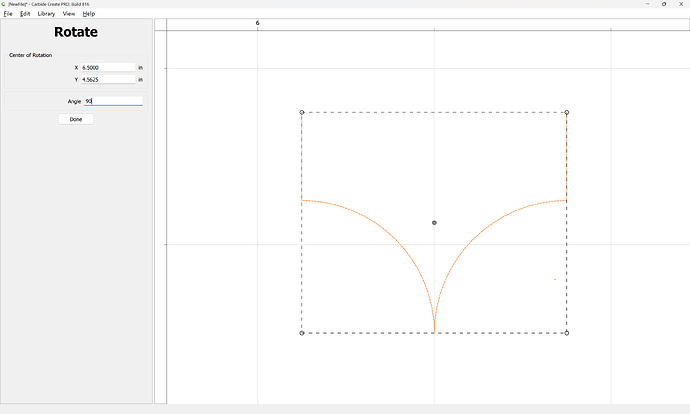

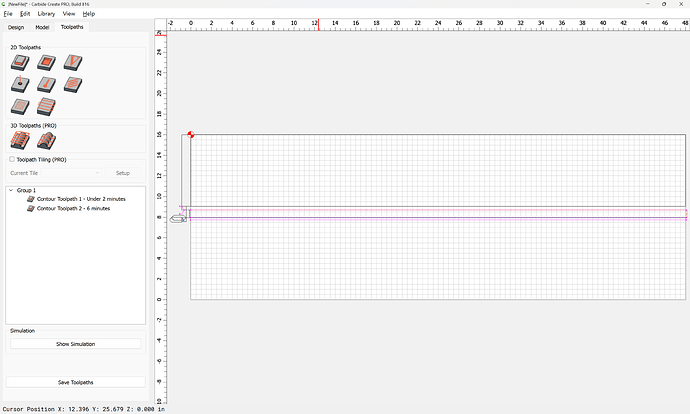

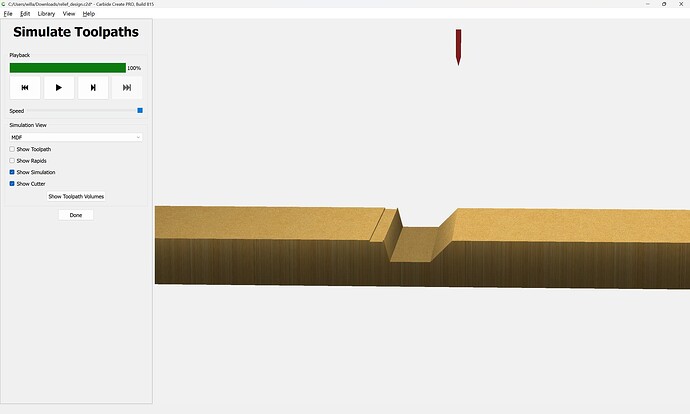

Since the piece is symmetrical top/bottom, the assumption is one will do only one side, then rotate it 180 degrees and cut the other, see:

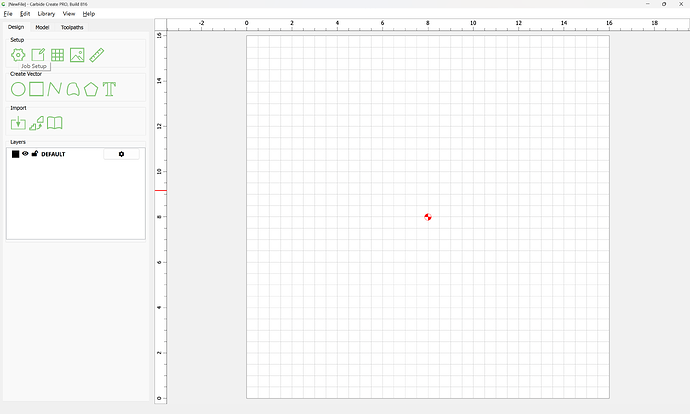

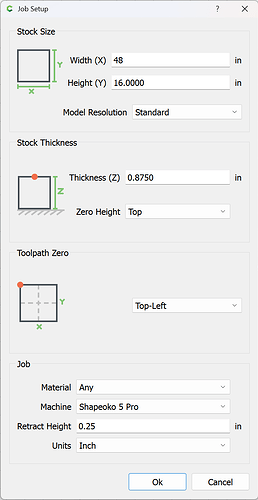

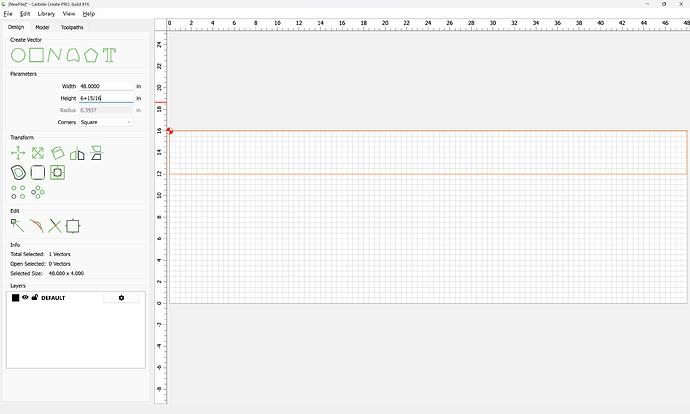

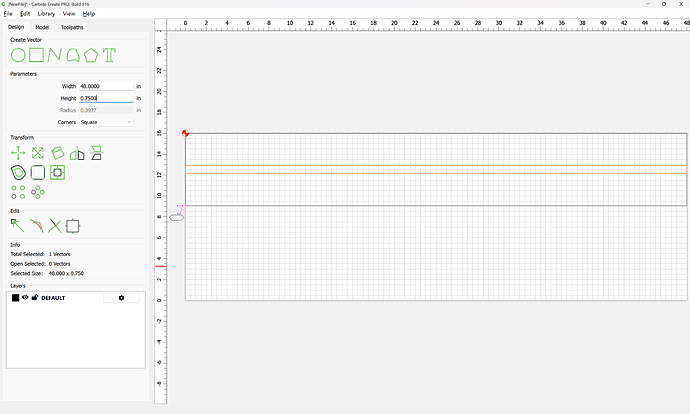

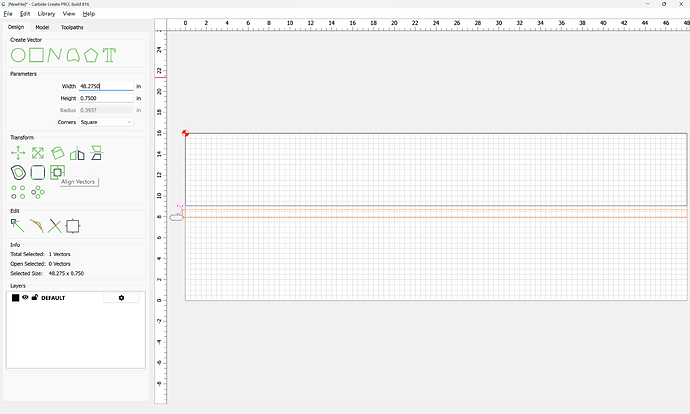

First, we set up the job:

for further details on this see:

https://carbide3d.com/hub/courses/create/job-setup/

Note the setting of the origin at the Top-Left — the assumption is the piece may be taller than the Y dimension specified — this will allow this to vary (the excess height just sticks out the front of the machine) and the origin is at the back left. Similarly, since the job will be flipped, we use half the thickness of the actual stock since we only cut half the design at a time.

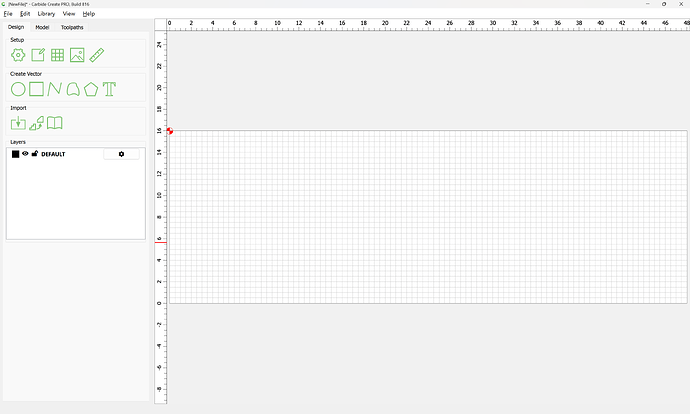

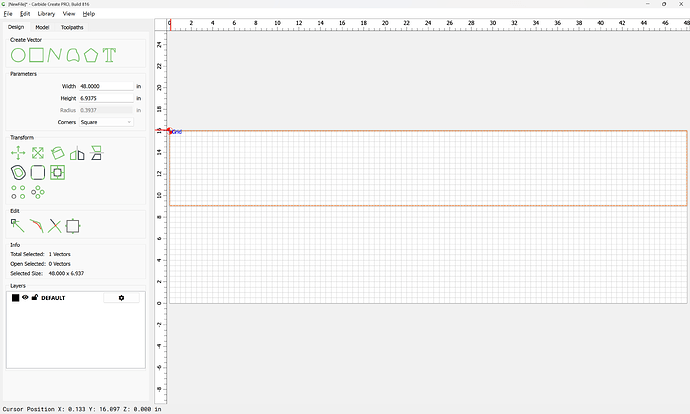

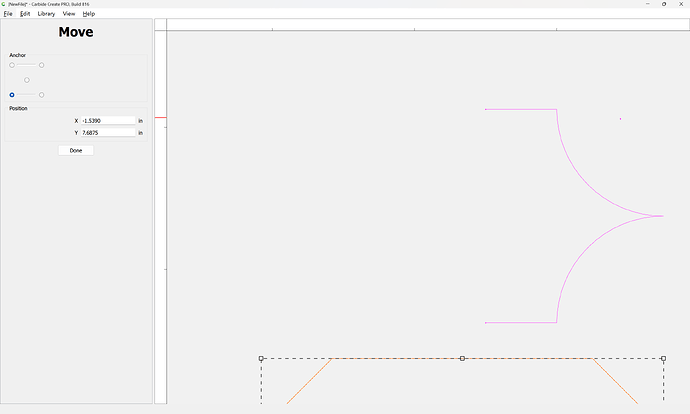

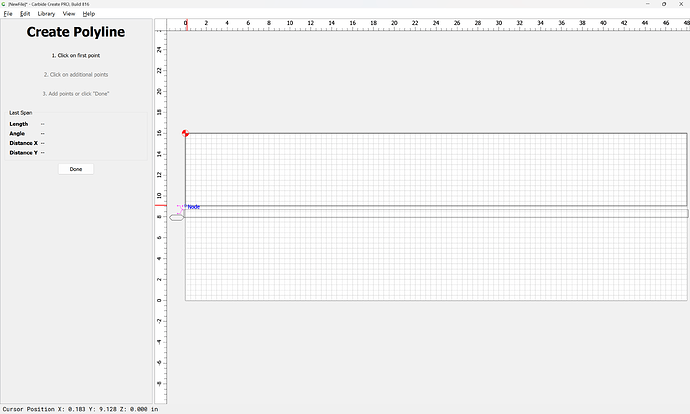

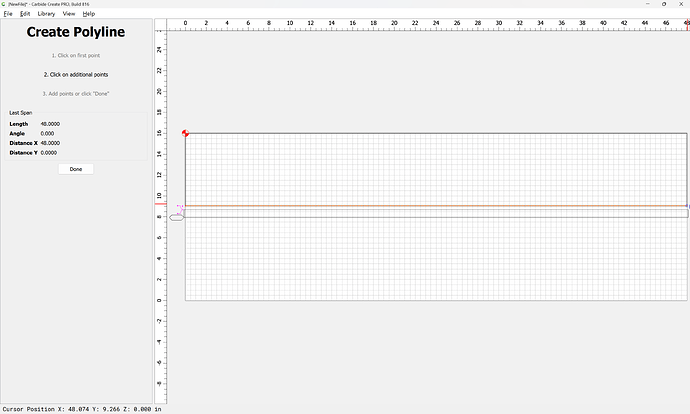

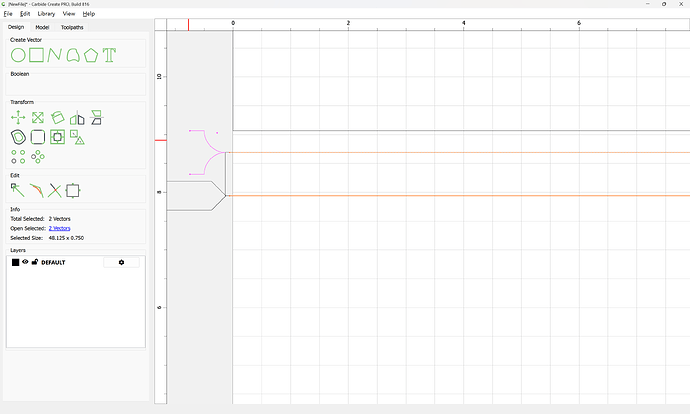

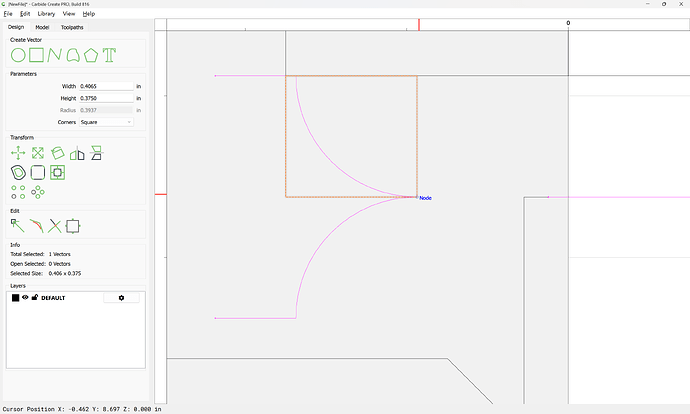

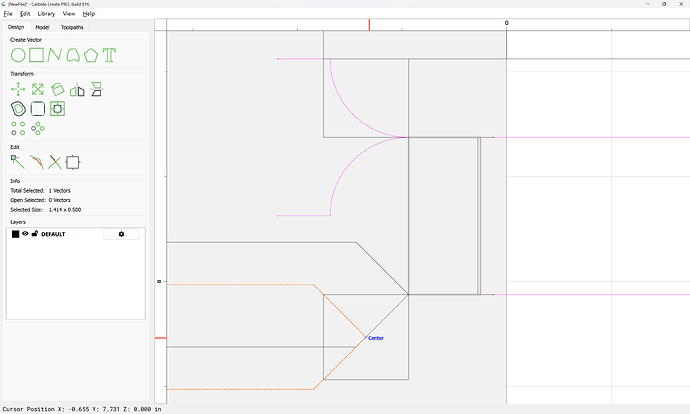

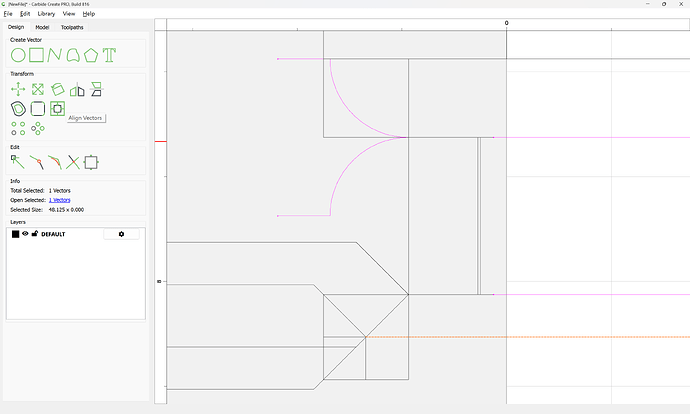

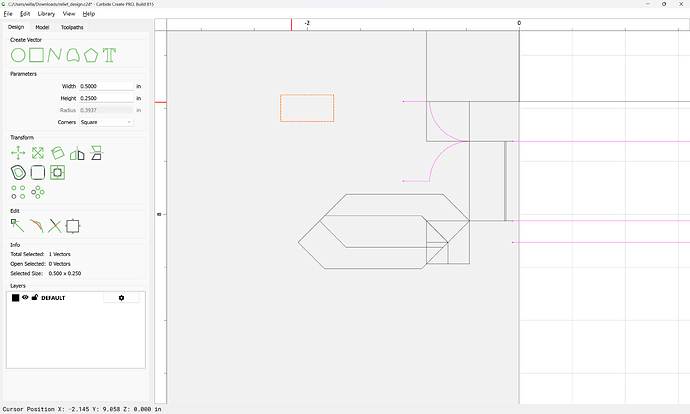

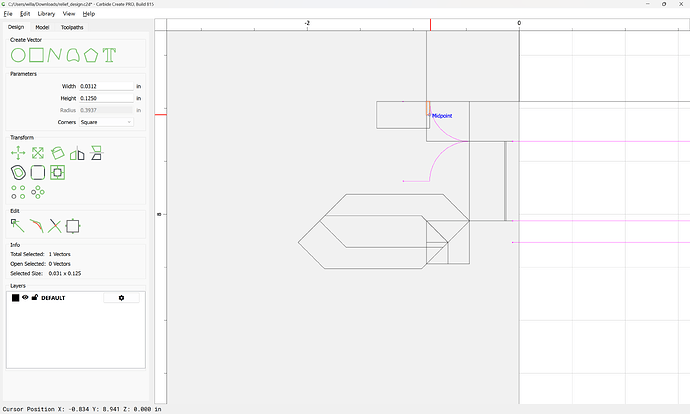

Then we draw up the design in profile to get the spacing/depths:

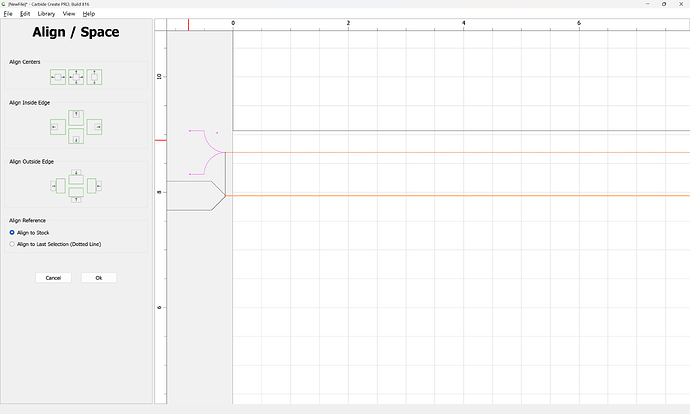

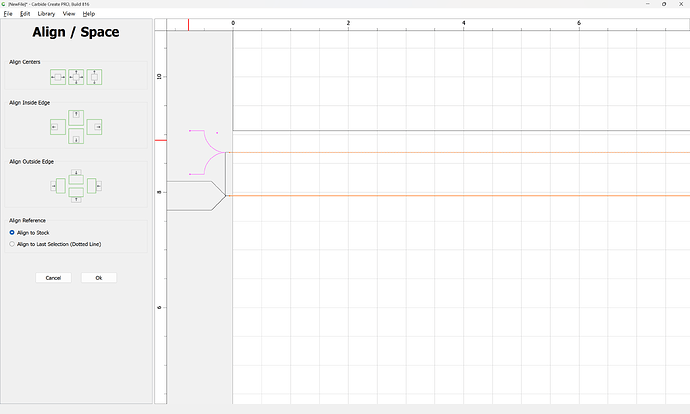

and if need be, reposition it:

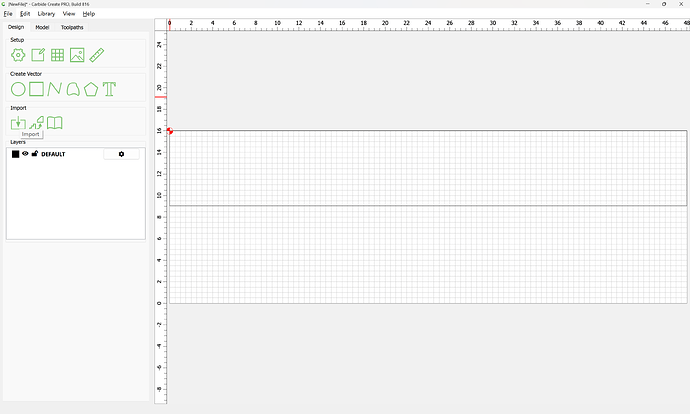

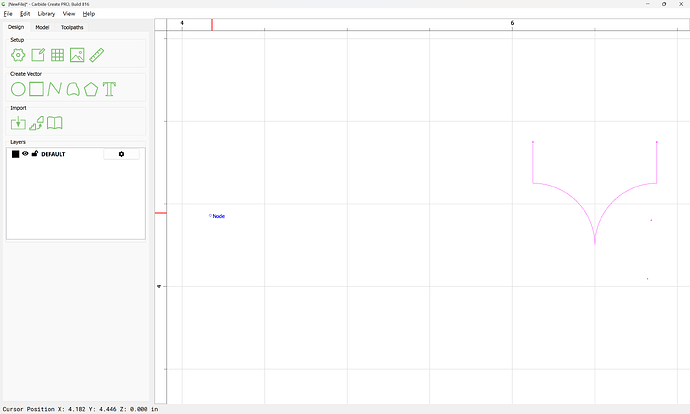

The 1574 has a DXF profile available:

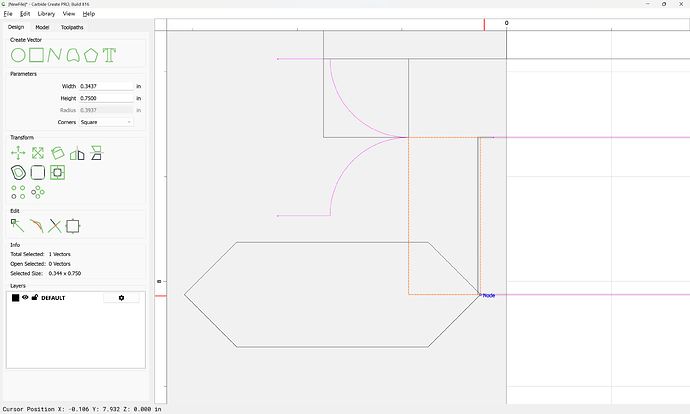

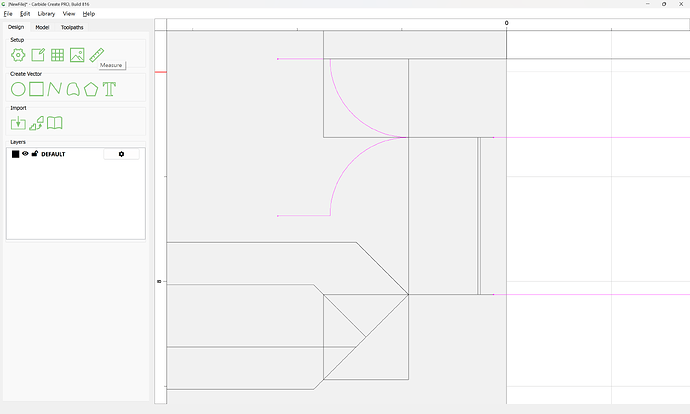

which we import:

Deleting what is not needed:

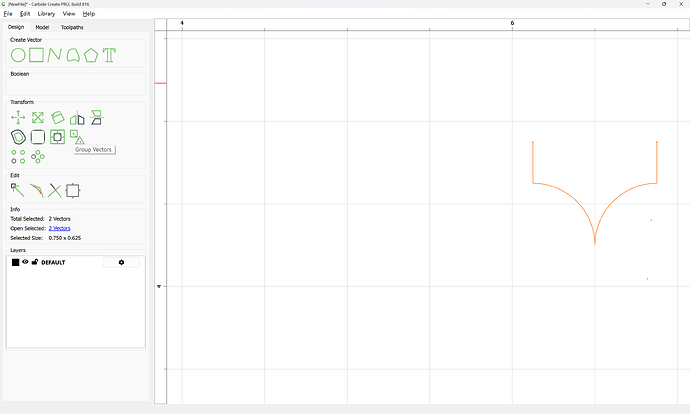

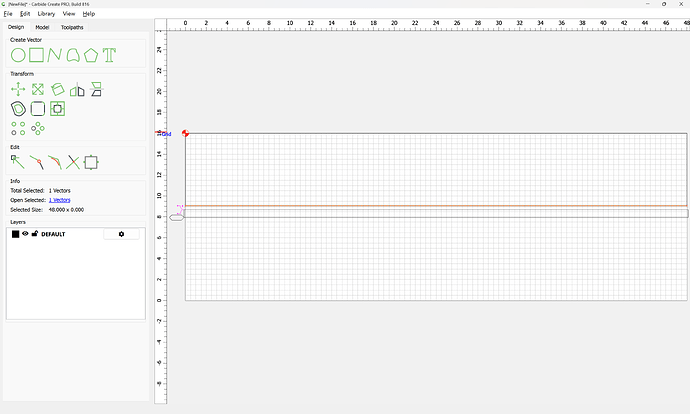

grouping what is left:

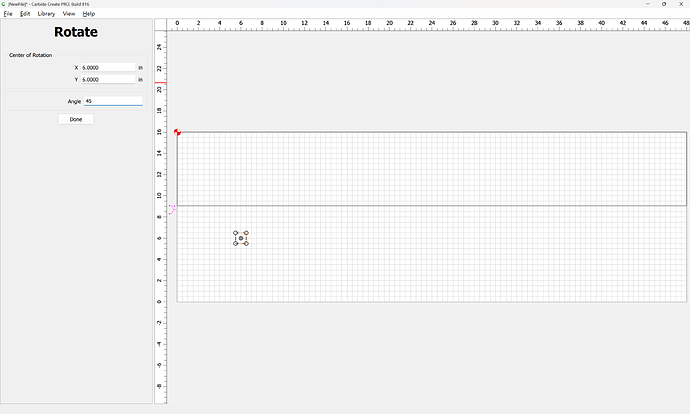

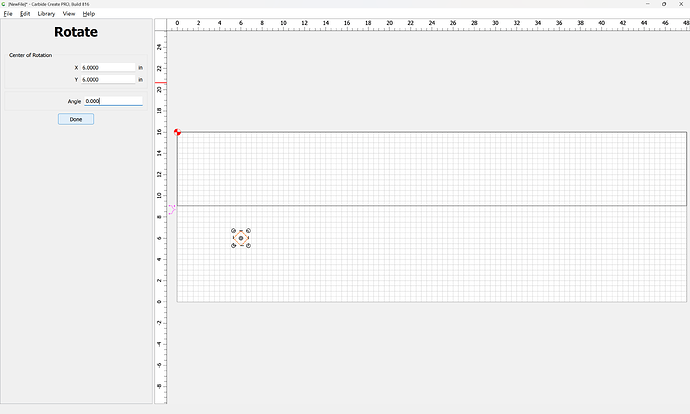

and then rotating it and positioning

it relative to the stock:

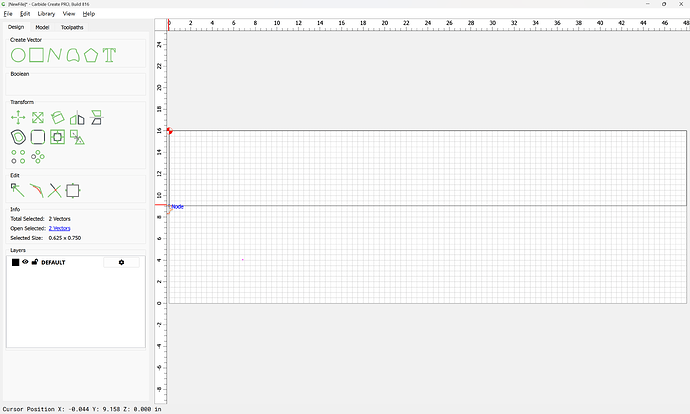

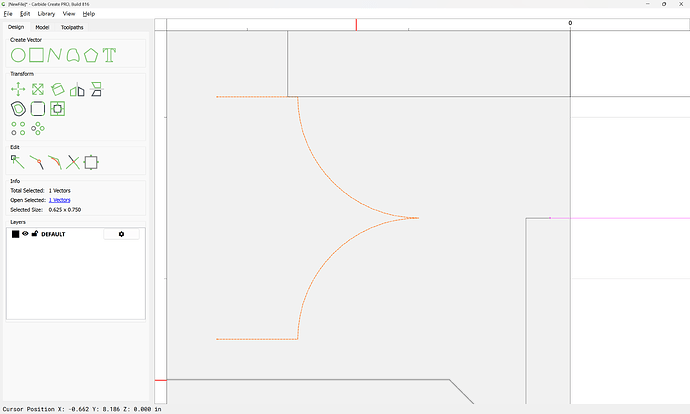

and nudging it out of the way to the left:

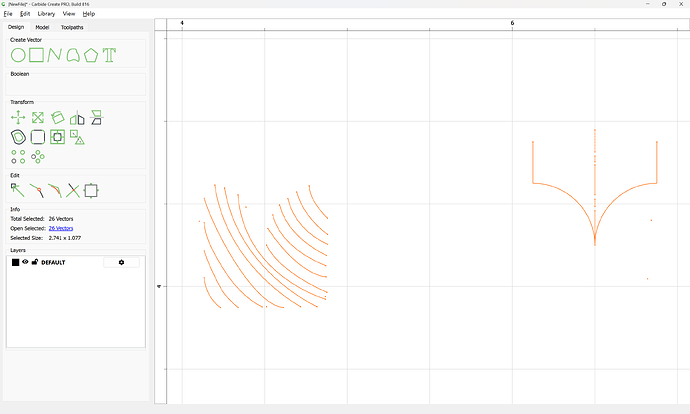

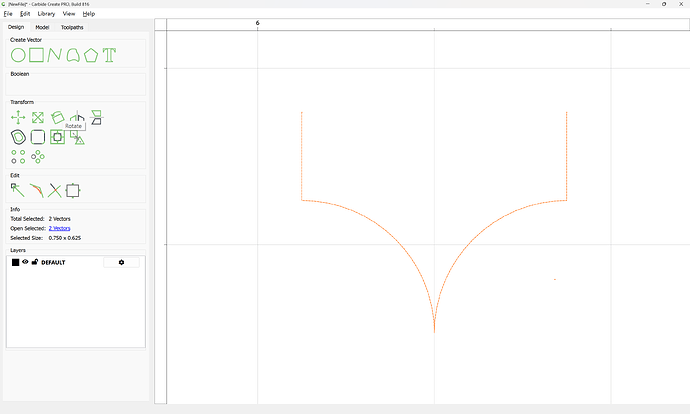

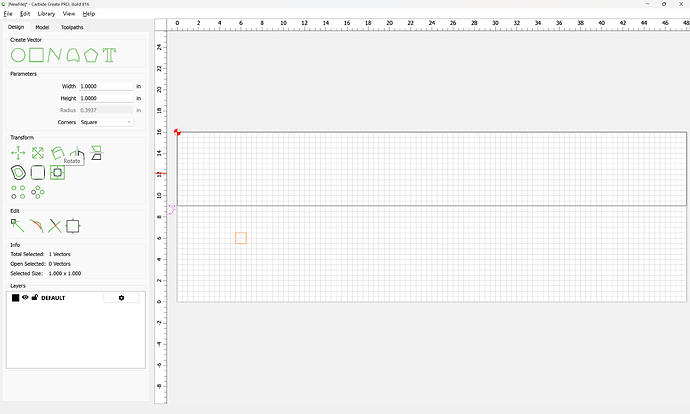

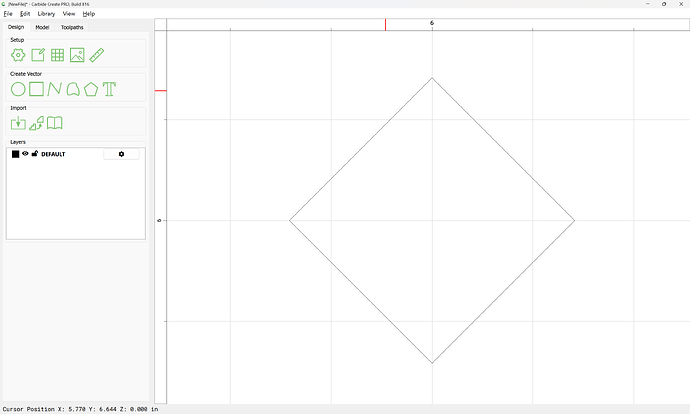

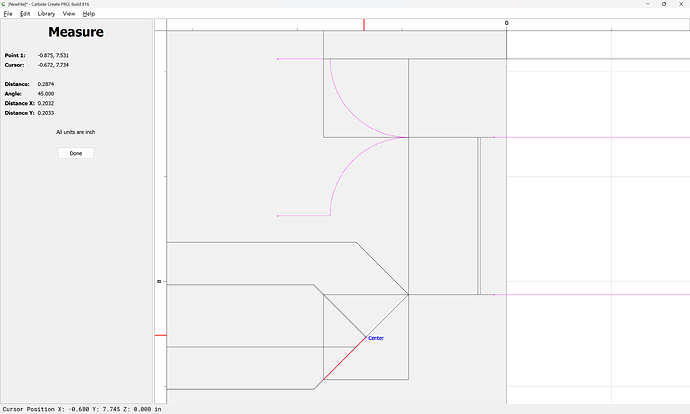

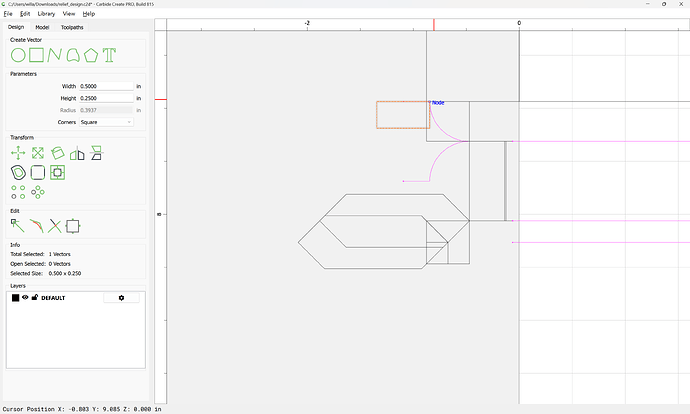

The angle looks to be 45 degrees, so will be cut with a #301 (or other 90 degree tool), so we draw one up:

Done

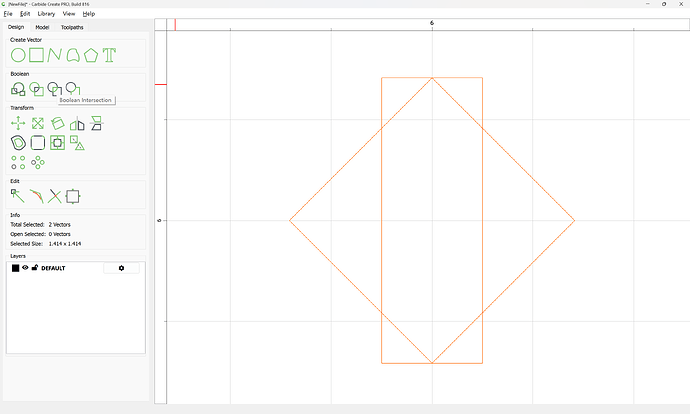

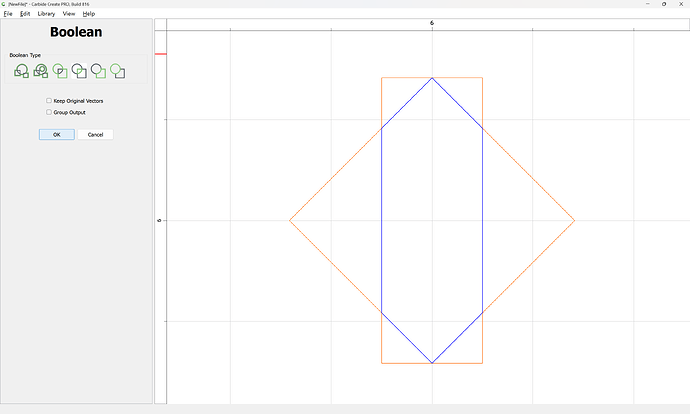

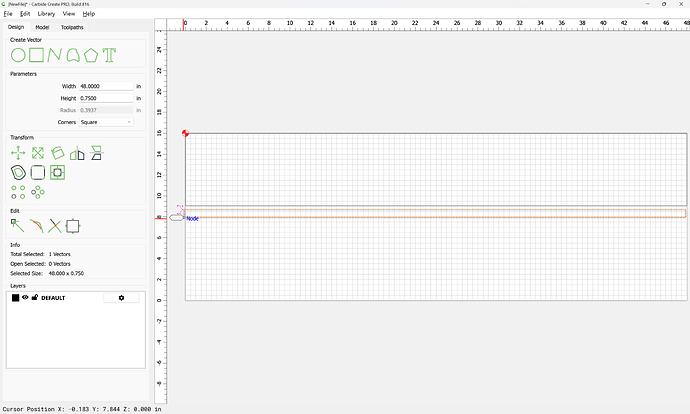

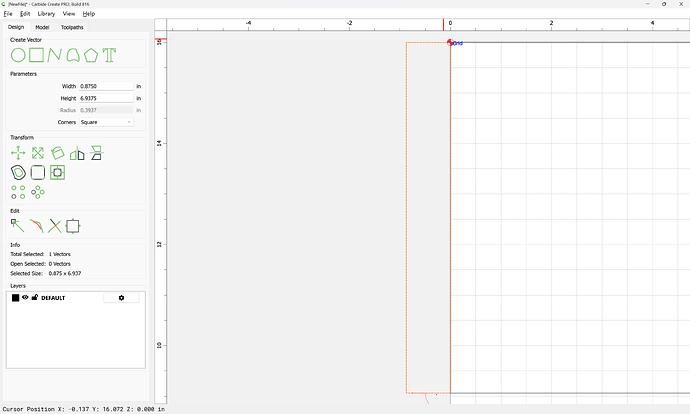

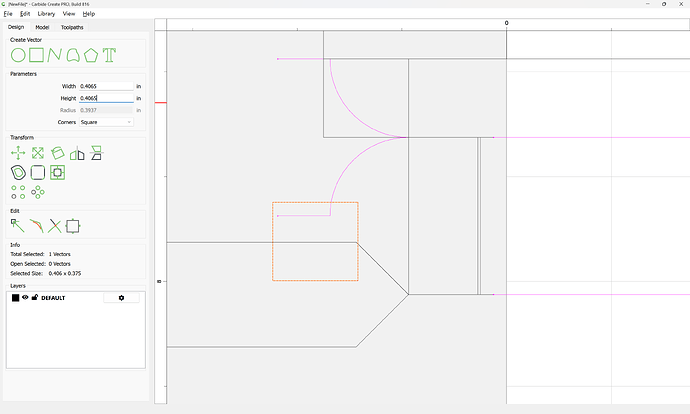

then draw in a rectangle:

and do Boolean Intersection:

OK

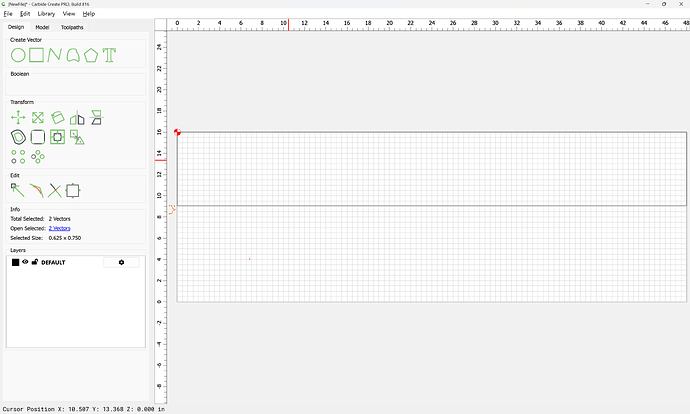

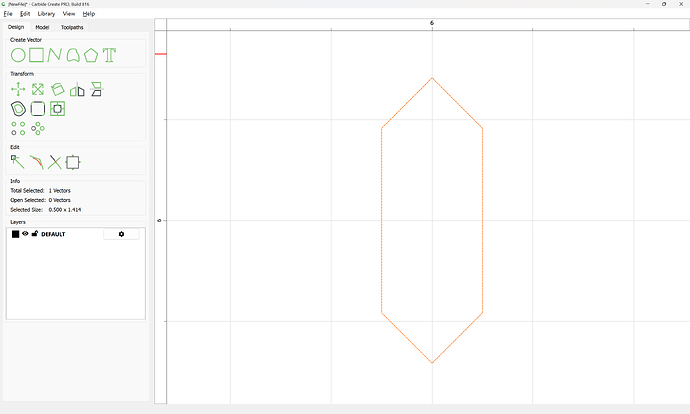

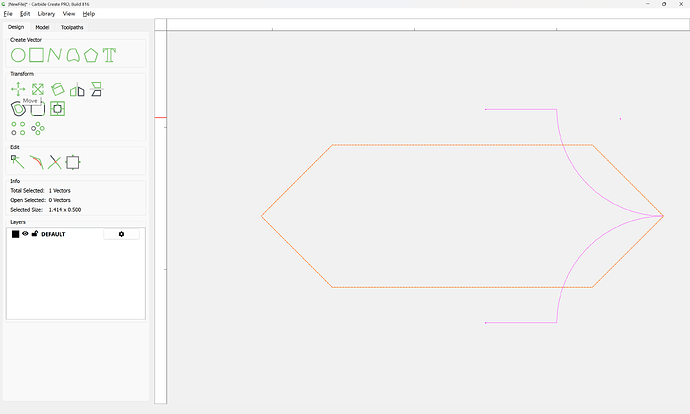

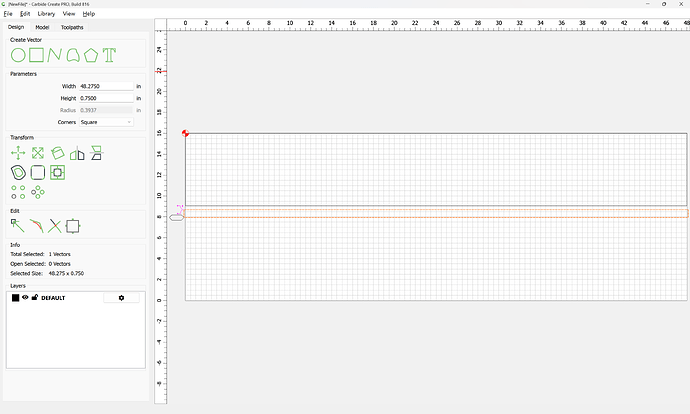

and similarly rotate and drag it into position:

It will be rotated 3/4" from the other tool:

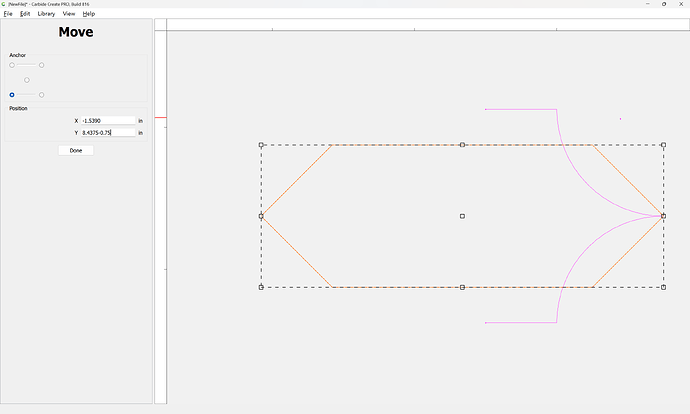

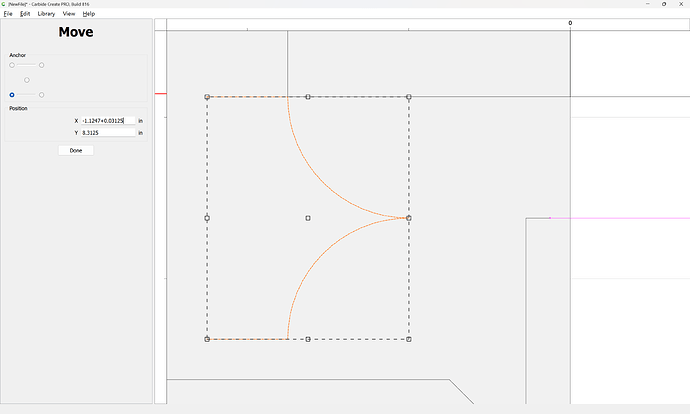

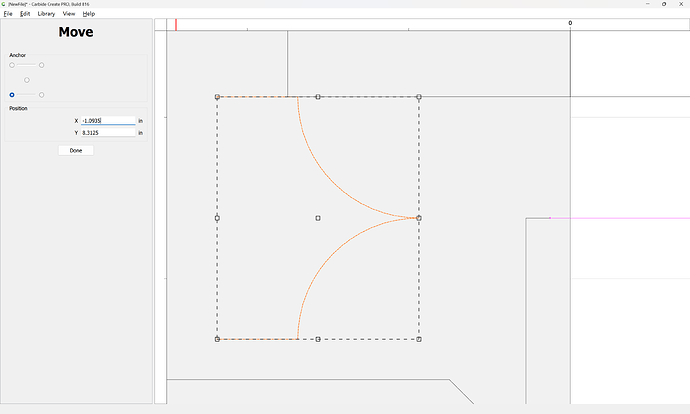

so using the Move command to re-position it:

Done

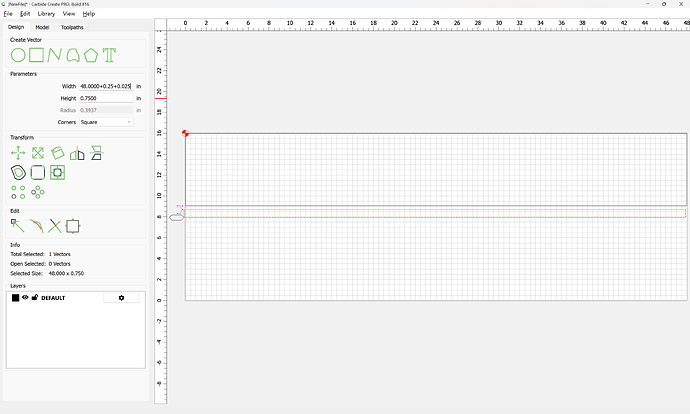

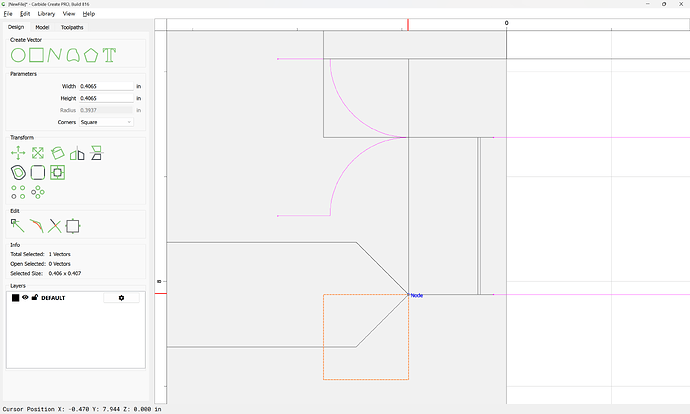

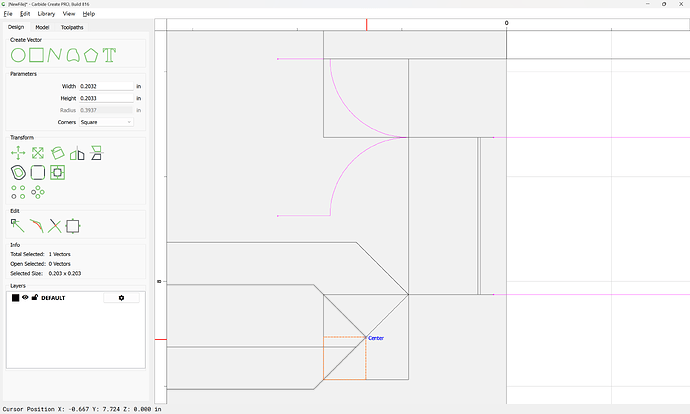

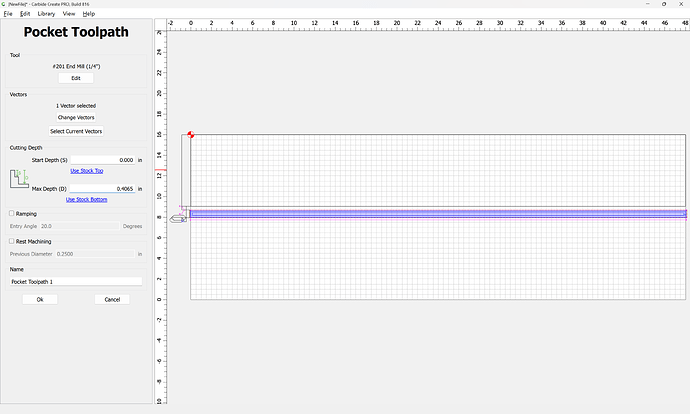

There will need to be a 3/4" high rectangle for a pocket in-between these twain:

which will need to be wider by at least tool diameter plus 10%:

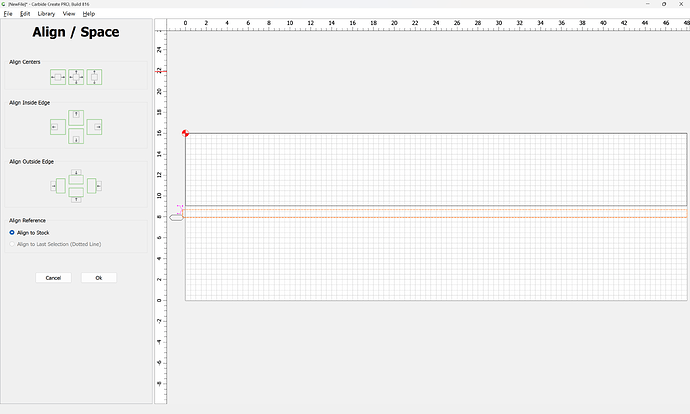

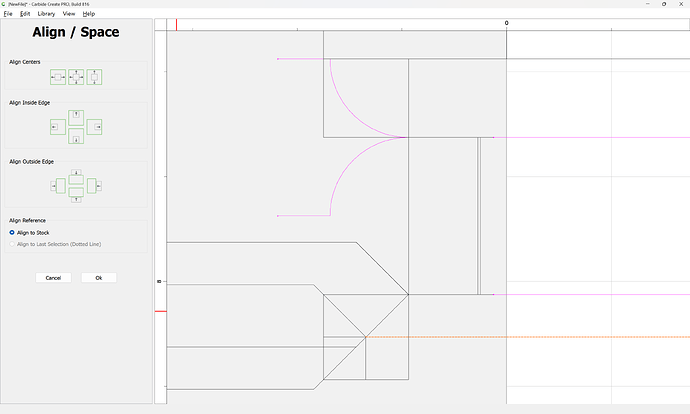

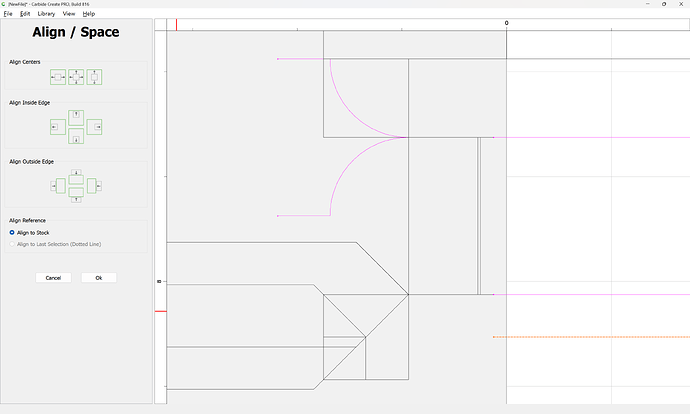

which should then be centered on the stock:

OK

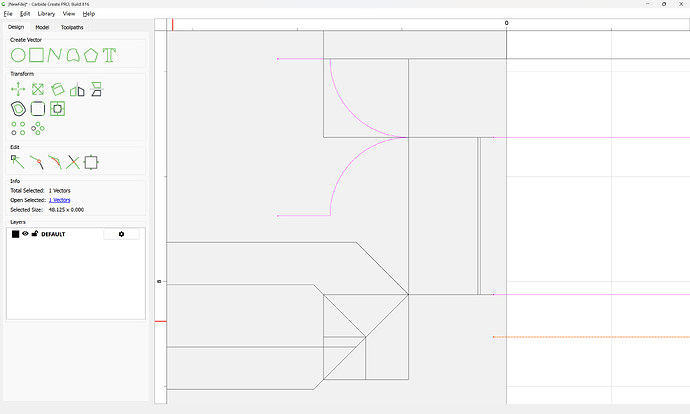

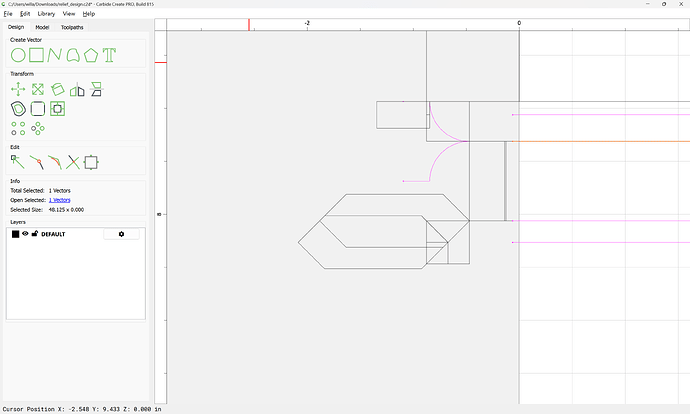

Similarly, there will need to be a pair of lines which are just a bit wider than the stock (or the rectangle may be duplicated and edited to create two separate lines)

Done

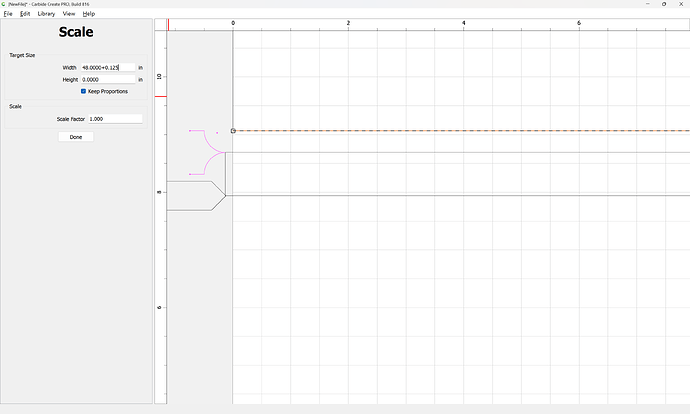

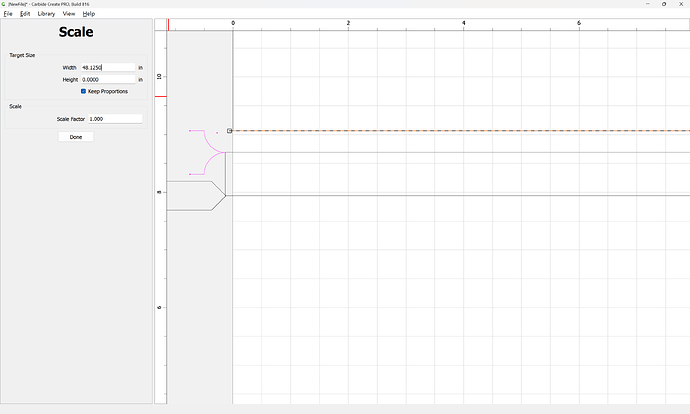

Scale

Done

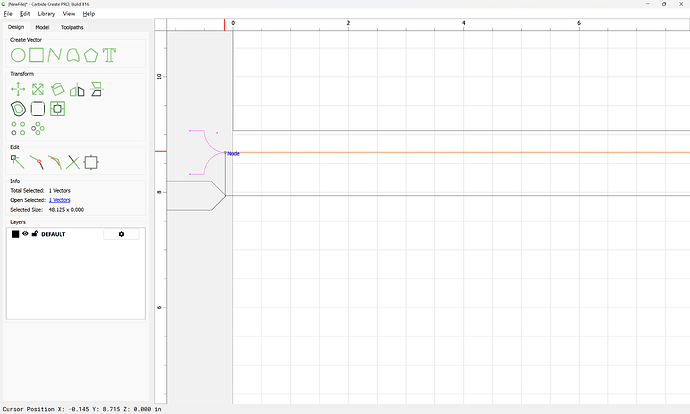

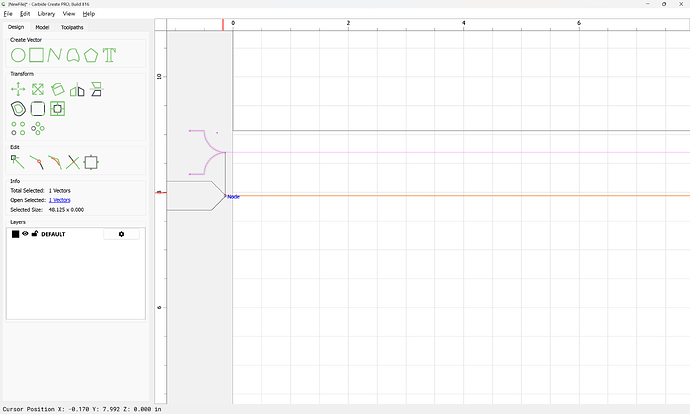

Again, drag these into alignment with their tool proxies:

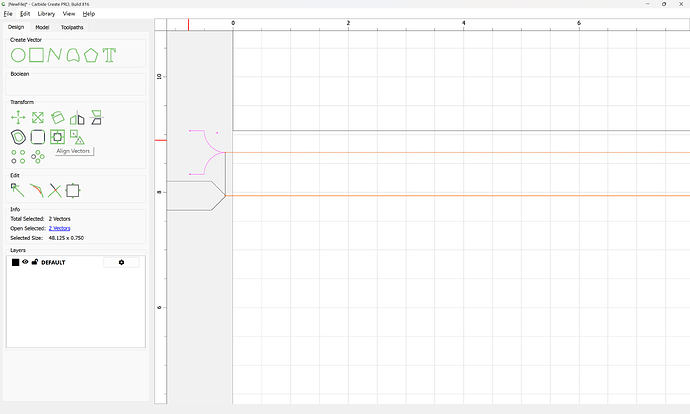

and align to stock:

Ok

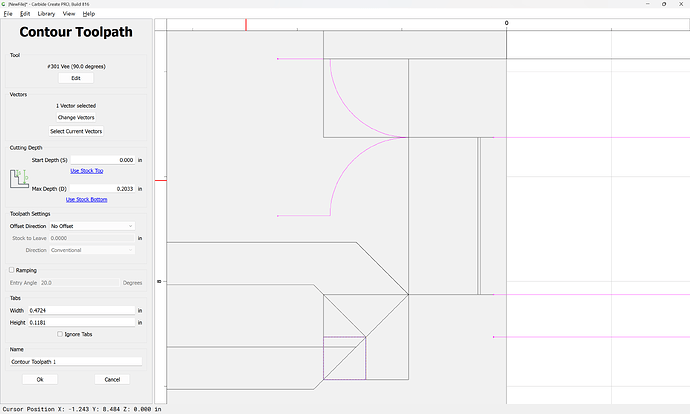

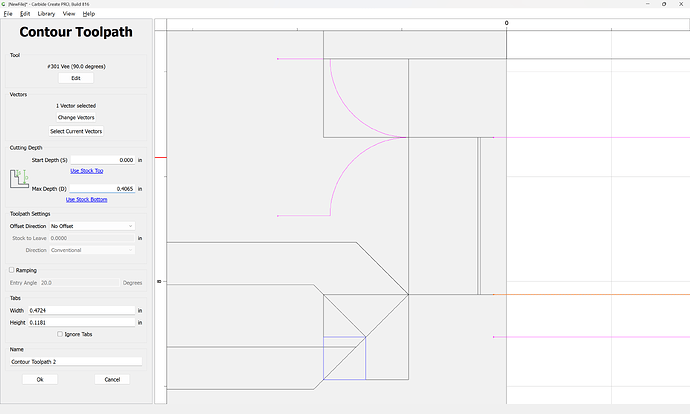

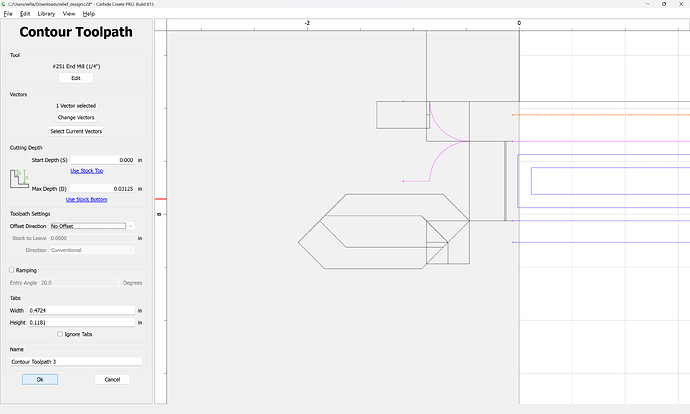

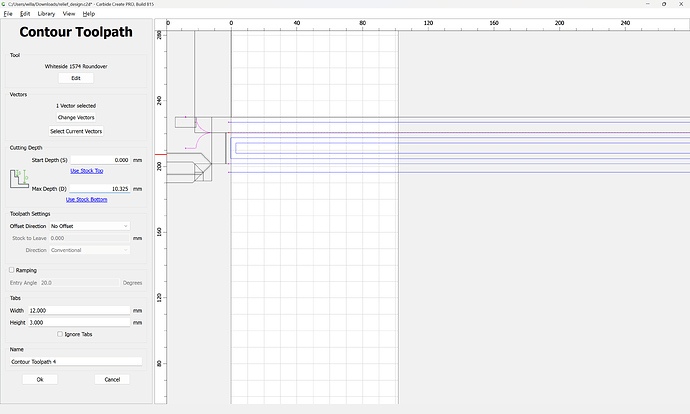

At this point it is simply a matter of assigning toolpaths, which is pretty obvious, and if desired, adding a set of V toolpaths to approximate the roundover cut.

Note that the #301 is too small to make this cut in on pass, so either a larger tool will need to be used, or multiple passes will be made.