Re-worked this w/ the lid integrated w/ a hinge:

and the lid made to work using roundover tooling:

Needs a 15.5" long by 3.5" wide by 0.25" thick piece of stock.

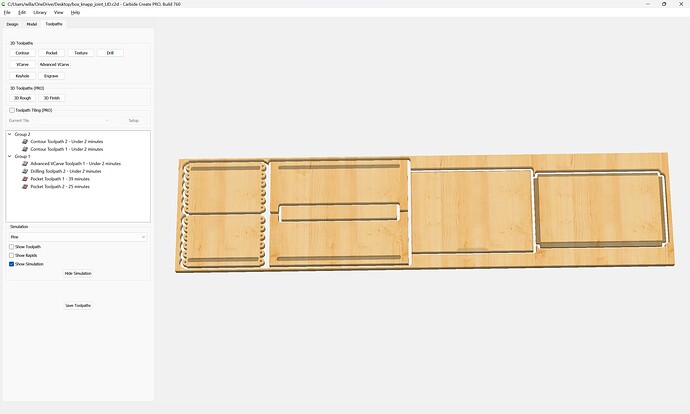

Getting ready to cut now:

New version w/ pocket clearing first disabled so as to save on a tool change:

box_knapp_joint_LID.c2d (592 KB)