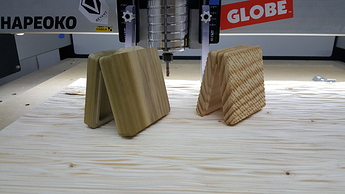

I hope this reply doesnt come off as pure boasting, and thank you for noticing. I am very proud of what you just pointed out and that most pieces coming off my Shapeoko require very little to no clean up. I use a short bristle craft brush and a Narex marking knife to clean up any fuzzies left behind. I have worked on my tool paths and feeds and speeds in earnest to get poplar and other softer woods coming off the machine with little to no clean up. I always thought it wouldn’t do me any good to give myself a bunch of hands-on clean up work by being impatient and cutting corners with my tool paths. Eventually my plan is to have 2 to 4 machines going at all times, and in that situation having to clean up each piece for more than a minute or two will add up quickly and I’ll fall behind with all the other work I do prepping stock, framing, and finishing. Now that my bragging session is over I would like to personally thank you @Julien and @gmack and everyone else who has chimed in to the constant feed and speed discussions around here. As a total newbie just over a year ago, you guys shared the knowledge that made good results possible, so thank you!

Looks like you stay busy - nice work! I too am trying to minimize sanding / cleaning especially on this mahogany that I got, it was some old T & G paneling in some exec’s office, it’s got nail holes in it, but that adds character. It likes to tear easily, but I think I’m zeroing in on the proper F & S. It also breaks pretty easy on very slim lines.

So that waterways sign you carved the flat bottom with a v bit, or v carved the water with the v bit and then pocketed with a endmill?

Thank you! I used the advanced vcarve toolpath with the clearance tool option selected. Bits used were a 60 degree vbit with a sharp point/no flat tip and a 1/32" 4 flute upcut bit for the pocket clearing. If you haven’t tried that new feature of CC yet, I encourage you to try it out. I have had a lot of fun playing with it. The more detailed the design the more manual cleaning has to be done in the few spots that the vbit is used to clear out a “flat” spot. I need to try running a bit with a small flat tip to lessen that clean up time.

Very nice work! Are you located in Knoxville? I am in Cleveland and just setup my Shapeoko XXL so am learning as I go. This is some beautiful work!

Annette

Thanks for posting some of your work. I just got my Shapeoko a few weeks ago and looking for ideas and inspiration all the time. You mention a “flat bottom Vcarving feature in Carbide Create”. I am not seeing such a feature. Are you using Carbide Create Pro maybe? Thank you.

See:

Thanks for the quick reply. I have now loaded the latest beta and will be giving it a shot.

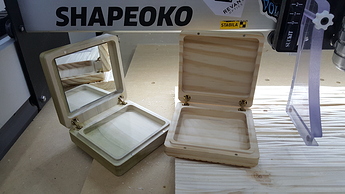

Very nice! I was looking at those hinges, how would you rate them? Wondering how they hold up to the weight of the lid.

These particular barrel hinges are from amazon and of questionable quality (low quality brass and casting/machining of moving parts). The lid on the poplar box is too heavy with the mirror for the hinge to actually hold itself in position reliably. They function well on the pine box as far as holding whatever position you open it to, but the box is so light it feels cheap. And the hinges do make some noise when operating which also leads to a feeling of cheapness. I think it would be worth a couple phone calls to local hardware stores to try and find something of higher quality. Or order online from an actual hardware dealer and not amazon.

I bought a set of these hinges recently. I did not use them yet but they are well made and sturdy, brushed Stainless steel. One problem is I can not find any latches that match.

There are some vendors listed at:

Usually an Ace or True Value hardware will have at least some solid brass hardware — also Rockler or Woodcraft will have a nice selection if you have one locally — I buy a fair bit of hardware from Lee Valley:

https://www.leevalley.com/en-us/hardware

For inexpensive stuff in suitable quantities I’ve had good luck purchasing from D. Lawless:

You can see a selection of different hardware on:

Looking into beginning to make some of my own though.

@WillAdams In the comments under that lumberjocks posting you mention the vinegar steel wool ebonizing, How did you like the final look of that (and the process) and did you ever end up “fuming” anything you have made? I have been curious to try that out as I love the look.

I really liked the ebonized look, except I found it difficult to get down into the open grain of the wood — my solution then was to use shoe polish, but subsequently spraying that with laquer resulted in a more delicate finish than I prefer.

In retrospect a better solution would have been to follow up the ebonizing solution with a dark stain which would get into the open pores.

I need to make a new case, but still deciding about materials and so forth — it’s also a bit challenging since I want it to accommodate all the possible variations I can put together now:

- 56" bow made from A-handle and #1 limbs

- 60" bow made from B-handle and #1 limbs

- 60" bow made from A-handle and #3 limbs

- 64" bow made from B-handle and #3 limbs

(and my cheaping out and not being able to justify buying Macassar Ebony for the case when it was recently on sale at Woodcraft — probably I’ll use bamboo flooring as a more affordable/sustainable option)

That does sound like quite the design challenge. Please keep us posted! I have spent afternoons playing with other coloring/finishing methods but I keep coming back to “custom” stain mixes and properly applied polys and lacquers due to my comfort/experience and ease of applying them.

Finishing is quite the art/science — I tend to stick to the traditional stuff (ebonizing, walnut oil, bee’s wax, spray lacquer) — there was a nice writeup I found on the basic principles which I came across ages ago which I’ve always regretted not capturing into the wiki.

I really want to try some walnut oil (off to amazon I go). From the pictures I have seen, it looks like it leaves a beautiful finish if the project is sanded well enough. (I guess that applies to any finish, really)

Edit: trying to avoid unnecessary “Bumps”. I love Mirka Abranet products for sanding bare wood up to high grit levels. Kinda pricy, but they last a long time and allow good removal of the dust as you work.

Actually, I just use walnut oil from the grocery store. For sanding I have a micro-mesh pack (which I need to supplement with a second which I can dedicate to wood).

I have been meaning to try the Mahoney’s product though, and there’s a “Walrus Oil” finish I’ve been curious about as well.

Looks like some pretty well trained monkeys. Great work.

Great links Will thank you! I was all oh wow im getting some Bruso stainless steel parts, then I saw the price and said nawww… 175 for a single 5 inch hinge!