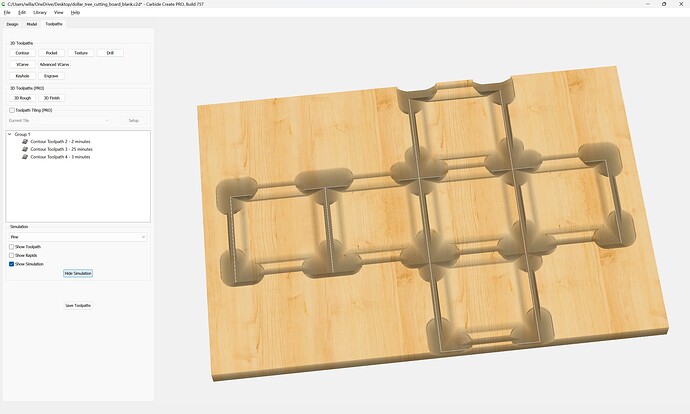

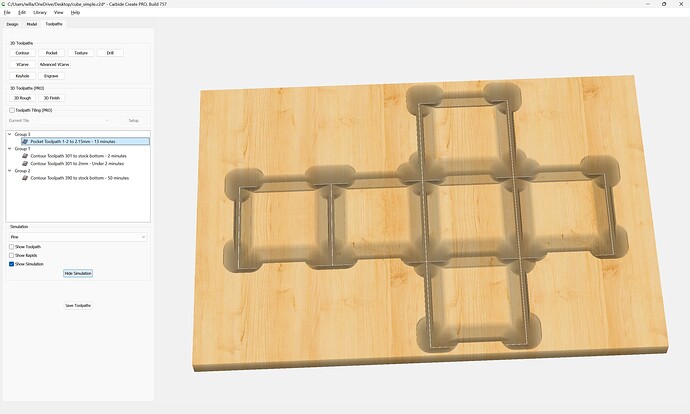

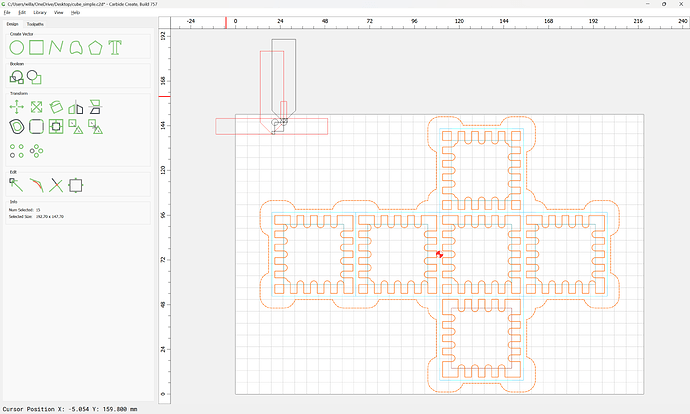

Revisiting this — the simplification is reducing the amount of geometry necessary by using a large endmill to cut the miter at the corners — the tradeoff is one can’t clamp at the corners, and more stock will be cut away at them.

Required tools:

- a small square endmill of a size which can cut completely through the stock

- a large V endmill which can cut significantly more than half-way through the stock

- a small/narrow V endmill which can be used to cut the V in-between the finger joints and the edges of the part

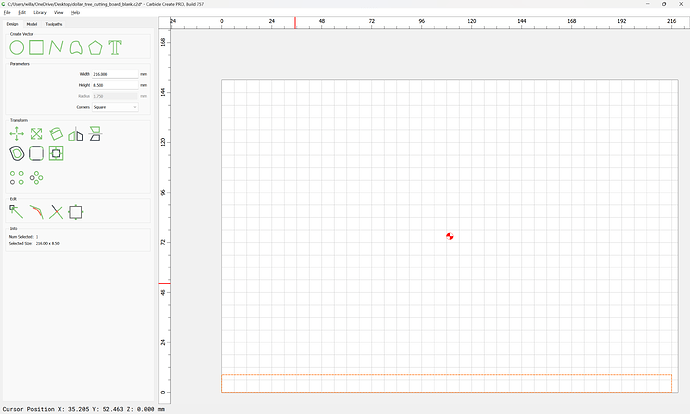

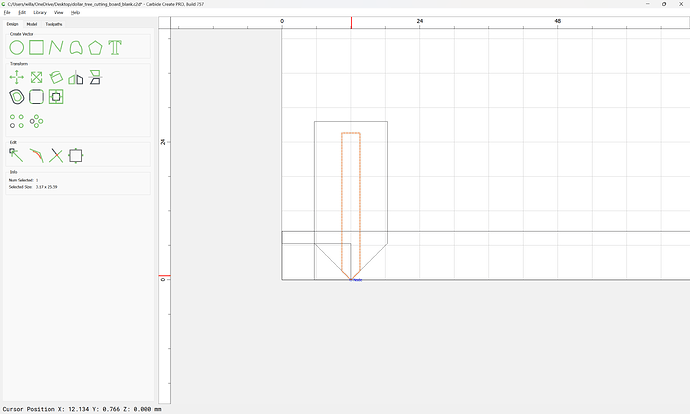

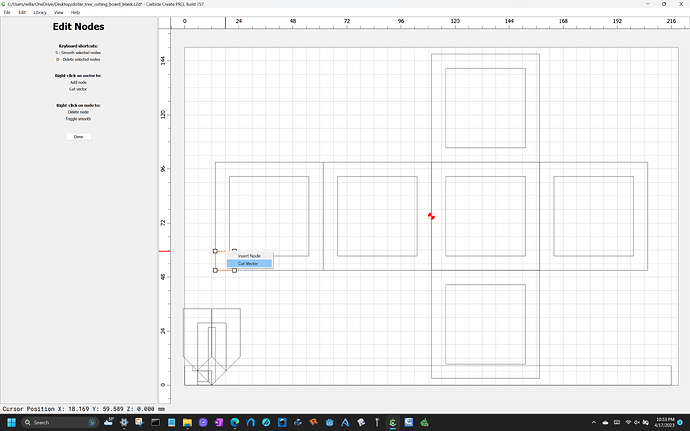

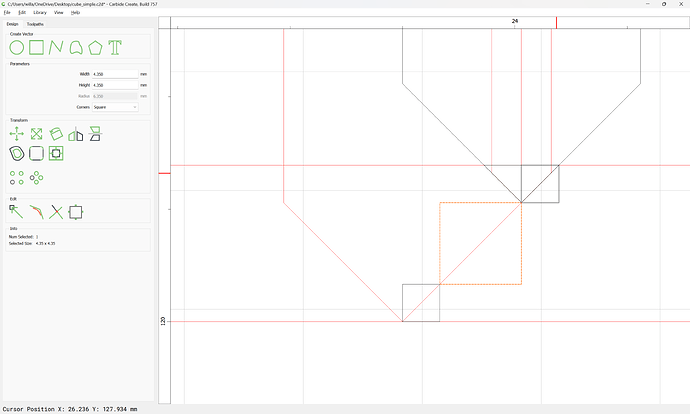

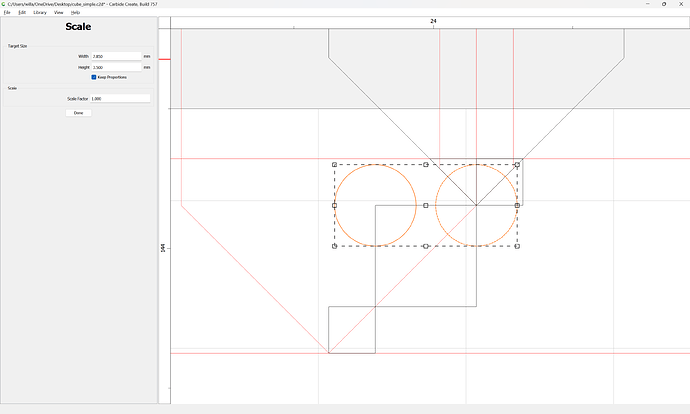

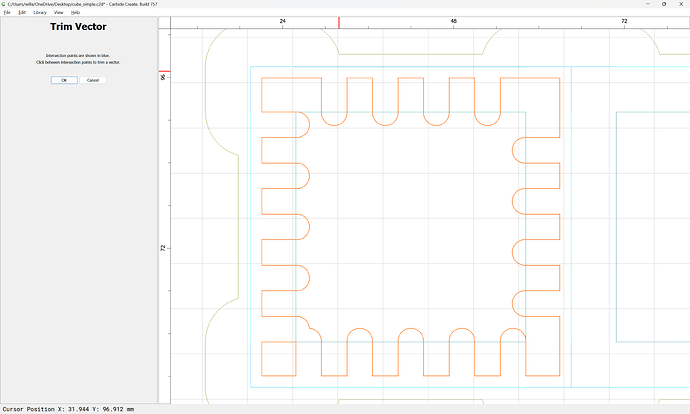

Start by drawing things up in profile:

(stock thickness is 8.5mm)

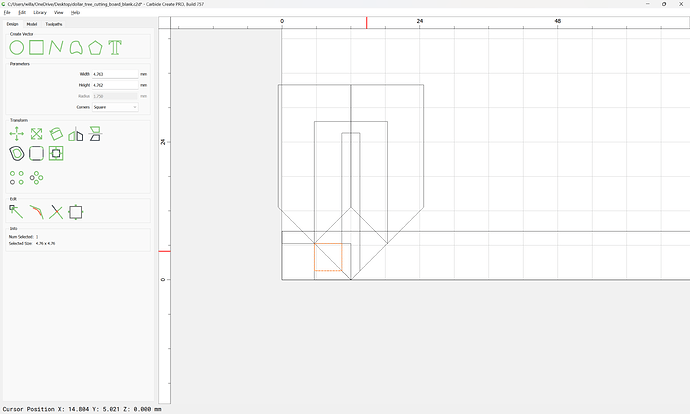

The larger tool is a #301 (or 301e for Essential):

(which has a cutting diameter of 1/2")

Though a tool such as:

might simplify things even further or perhaps yield a better result, but I don’t know if it’s $131.04 better.

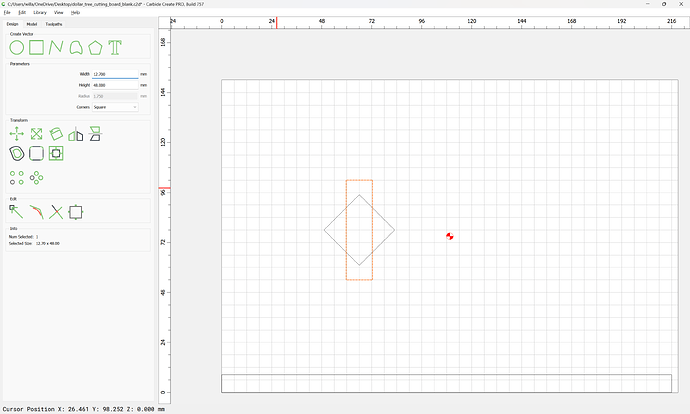

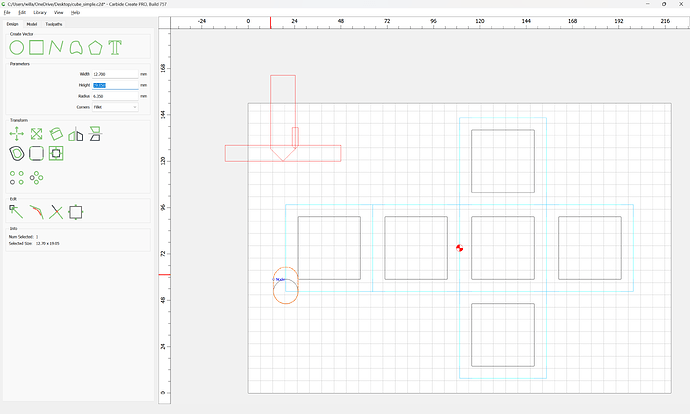

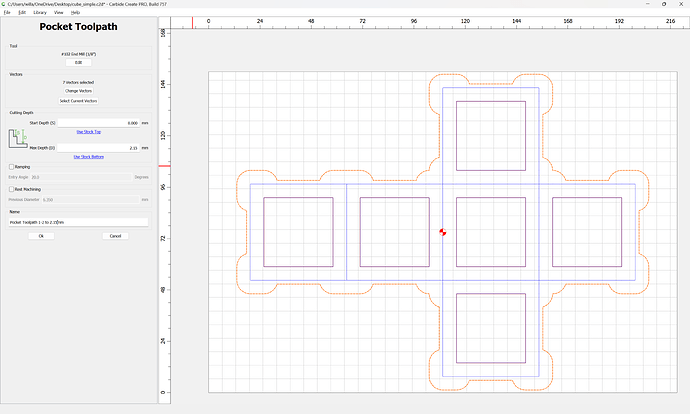

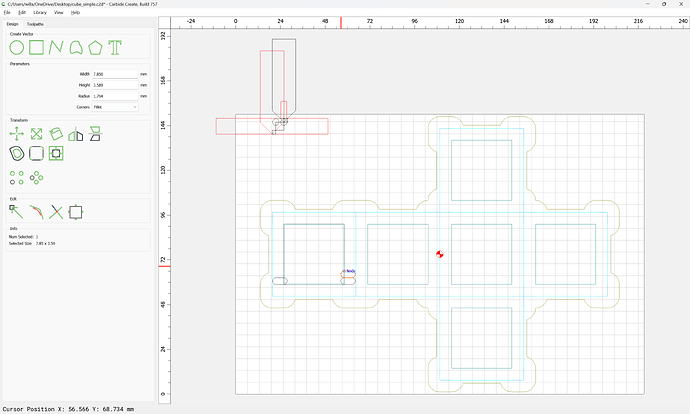

Zooming in after arranging the profile of the tool we see that we will need to cut

2.15mm deep to meet up with where the V endmill stops cutting the miter.

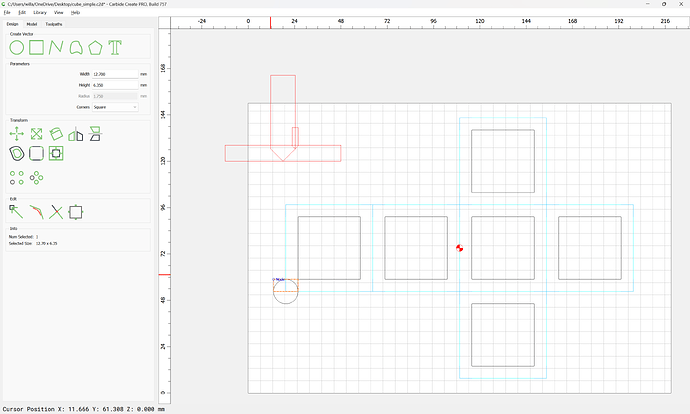

Measuring the tool we get half its diameter as the distance where that will be inset:

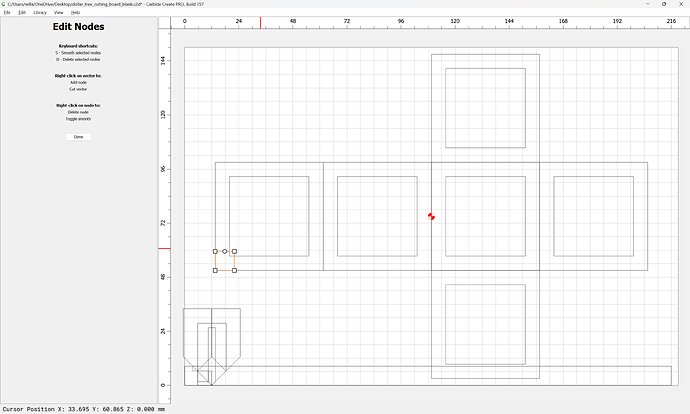

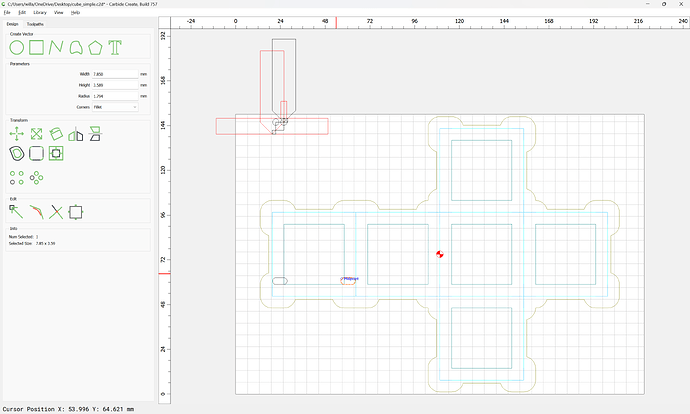

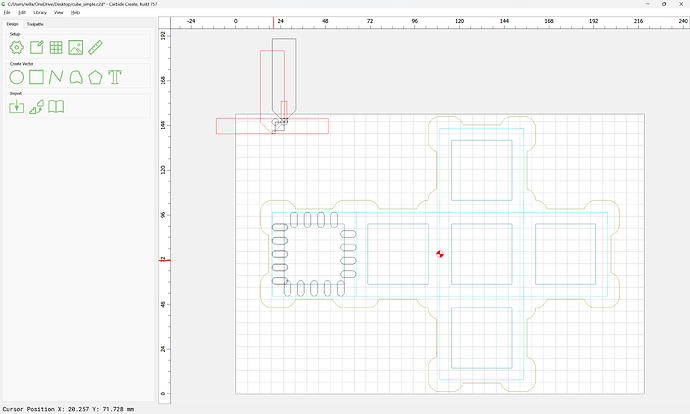

So we arrange things to show this and the other necessary geometry — the central cut with the smaller V tool:

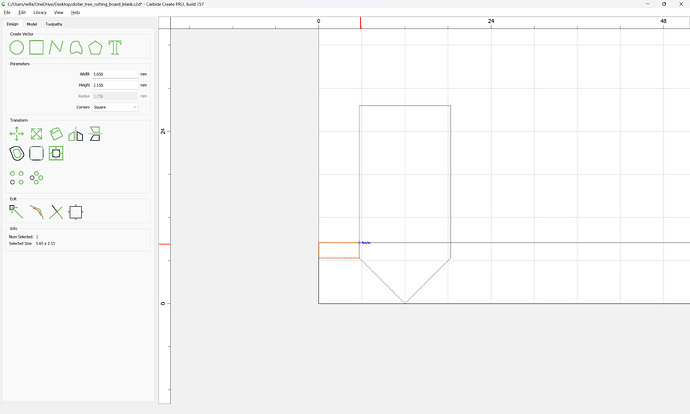

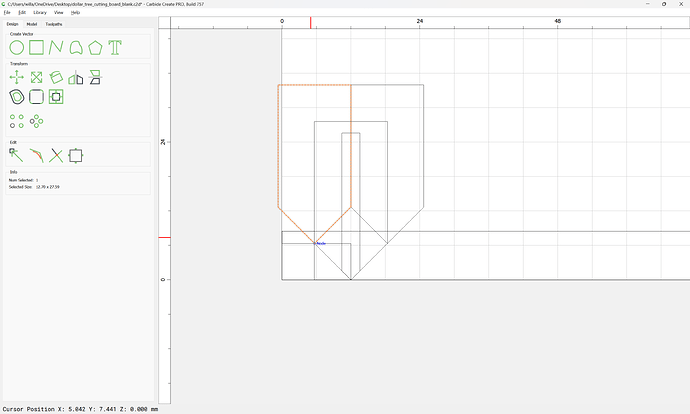

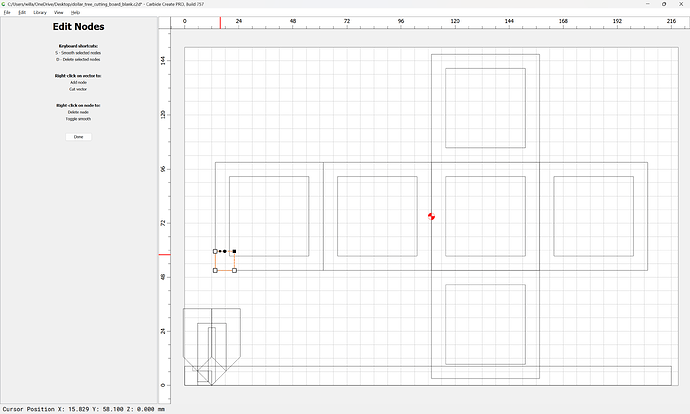

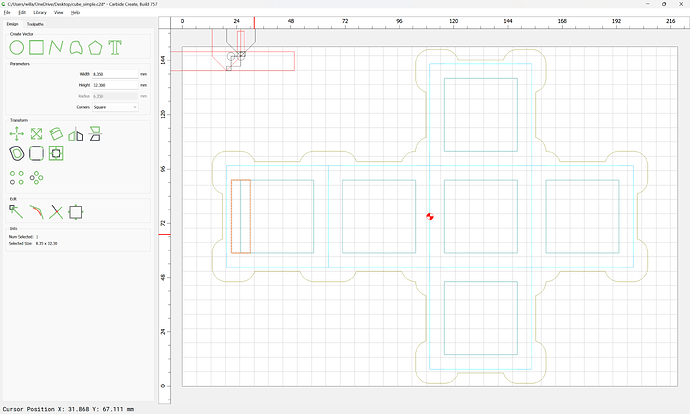

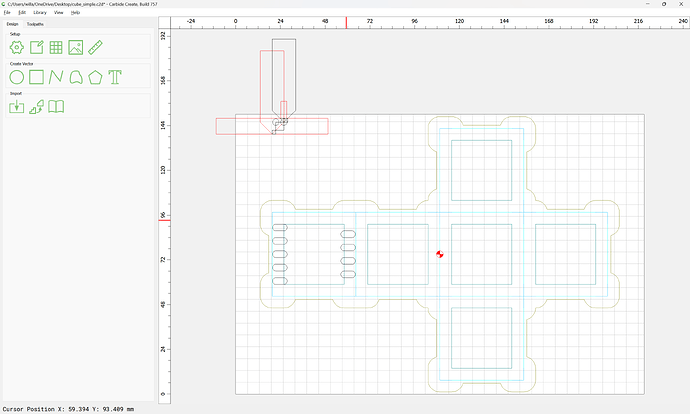

The cuts at the top of the finger joinery:

The geometry of the finger joinery:

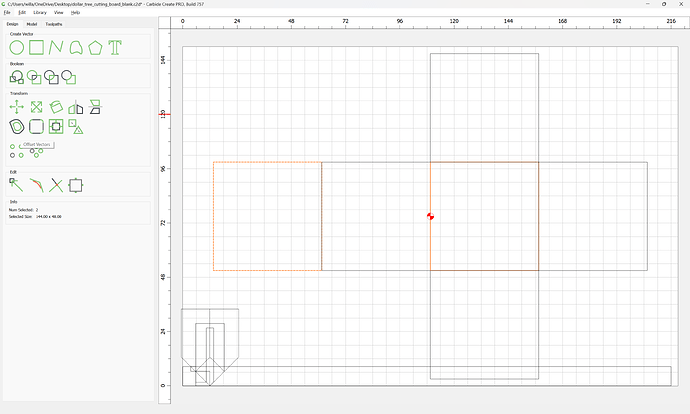

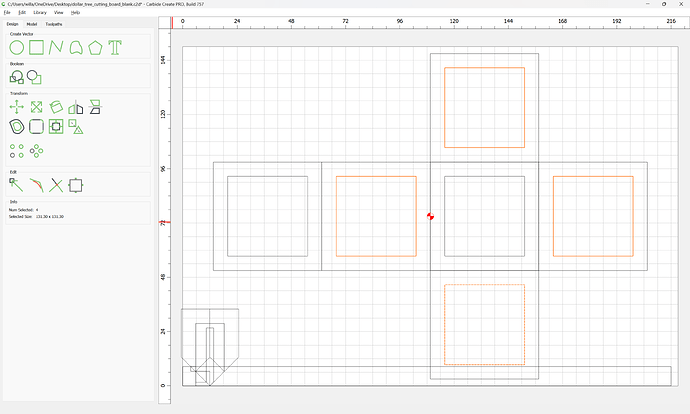

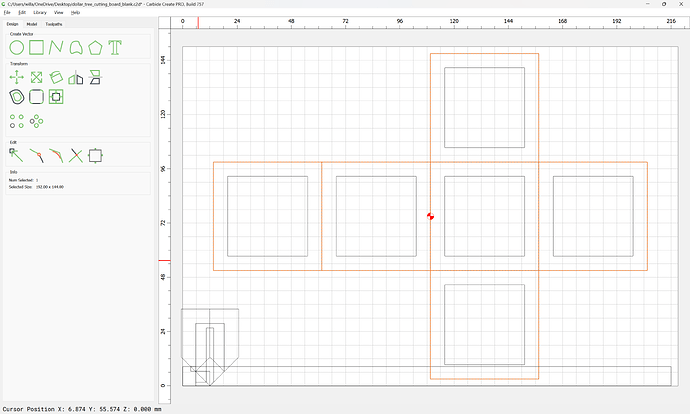

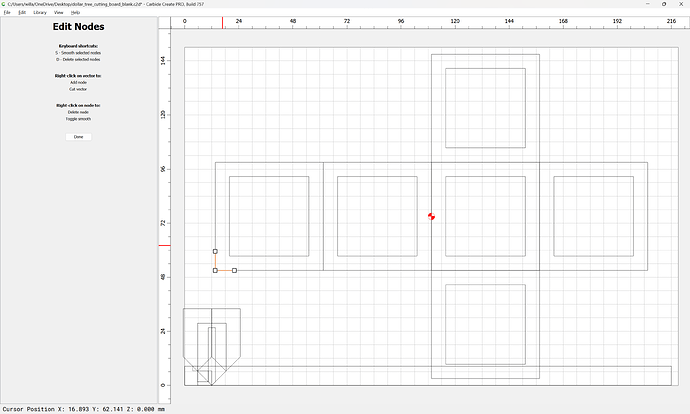

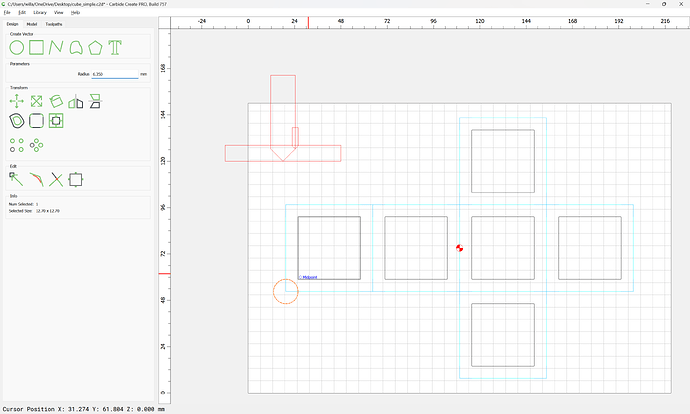

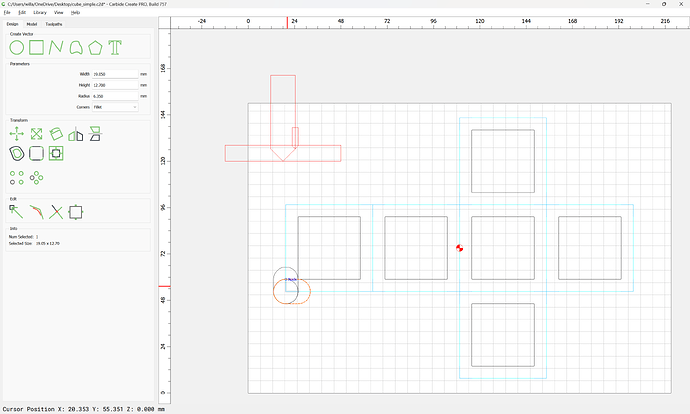

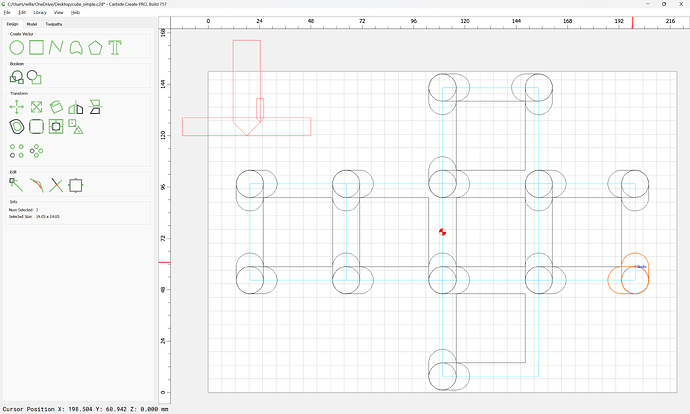

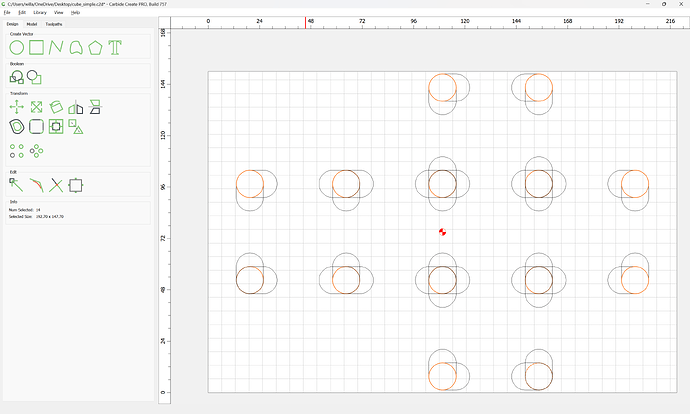

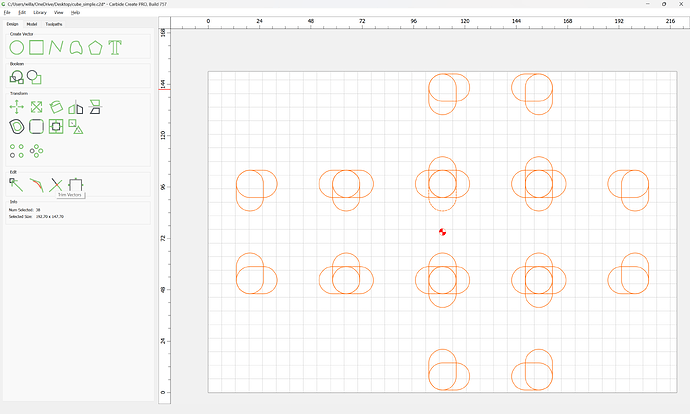

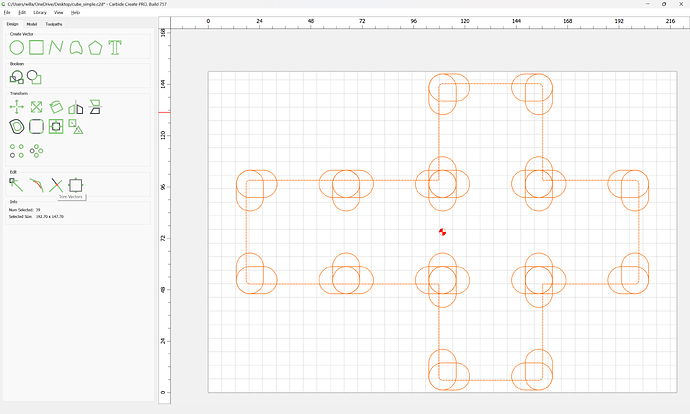

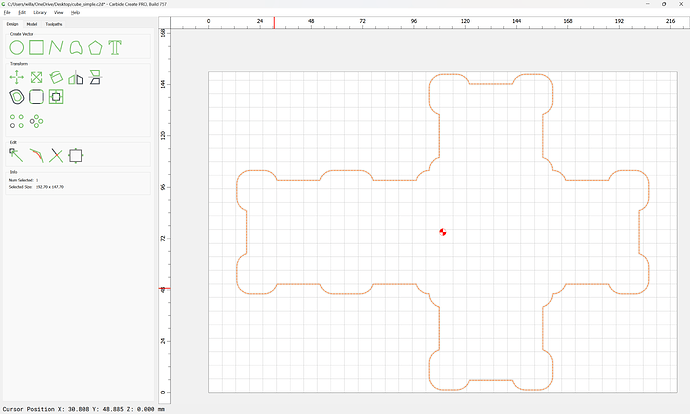

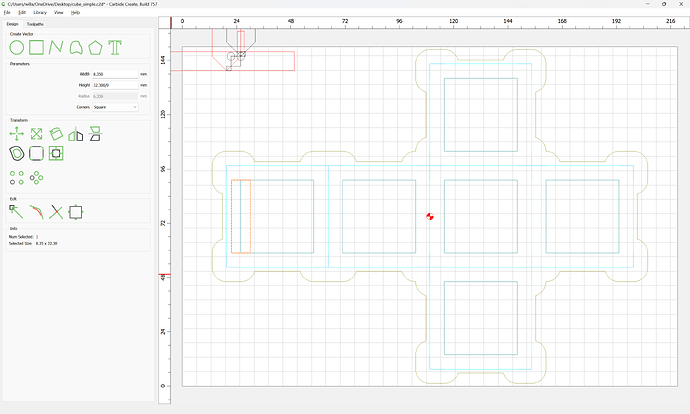

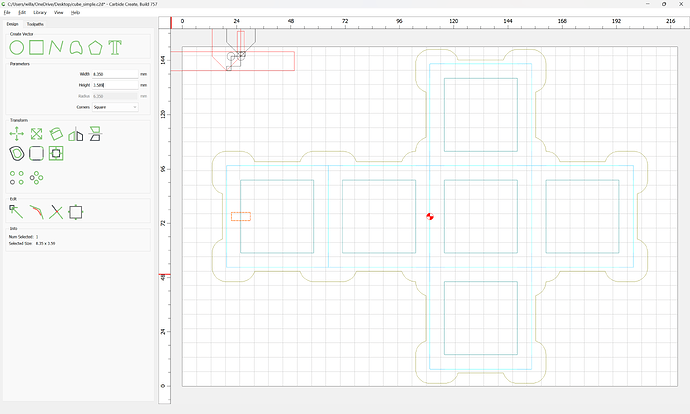

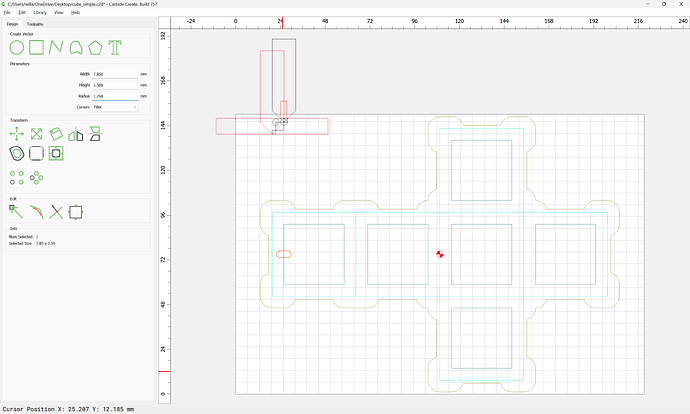

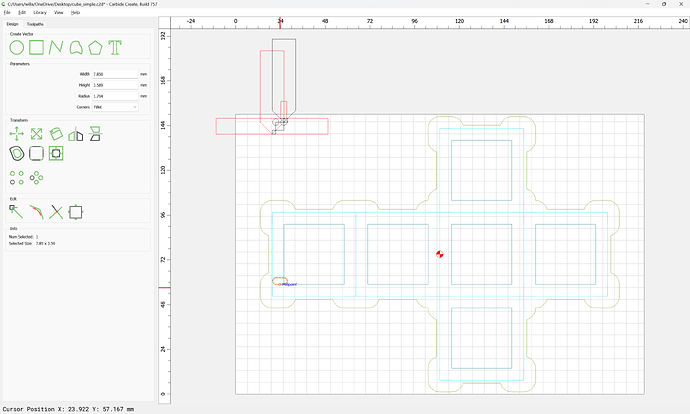

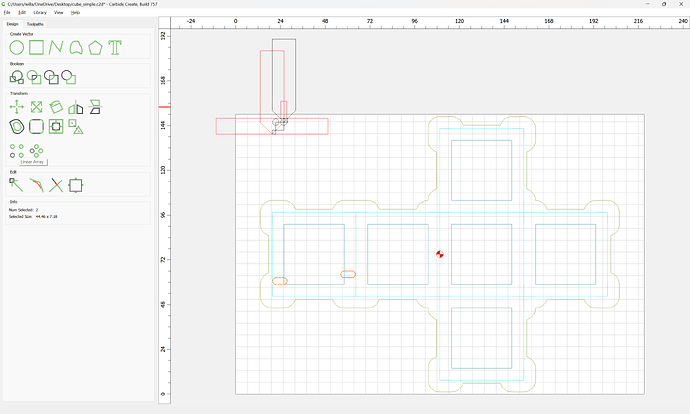

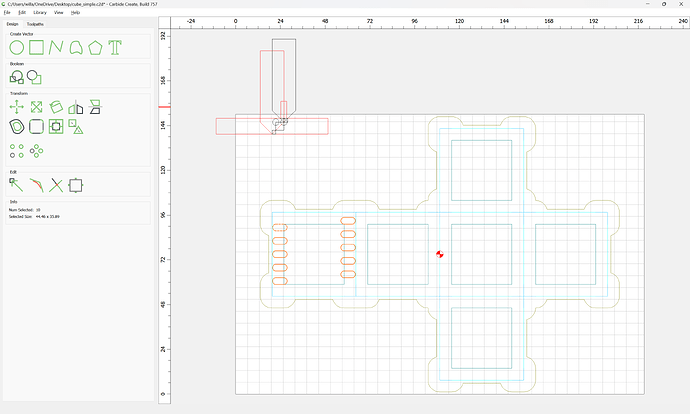

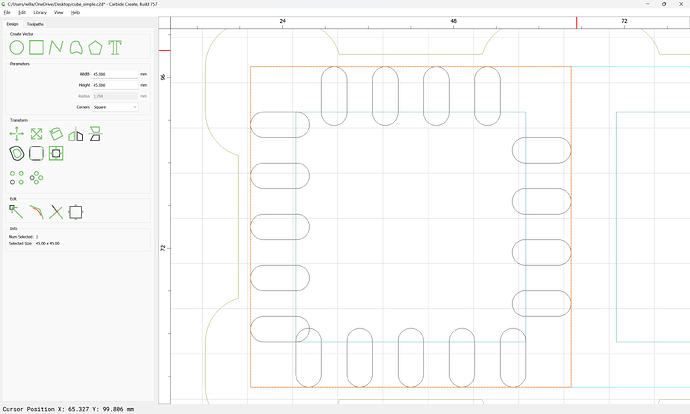

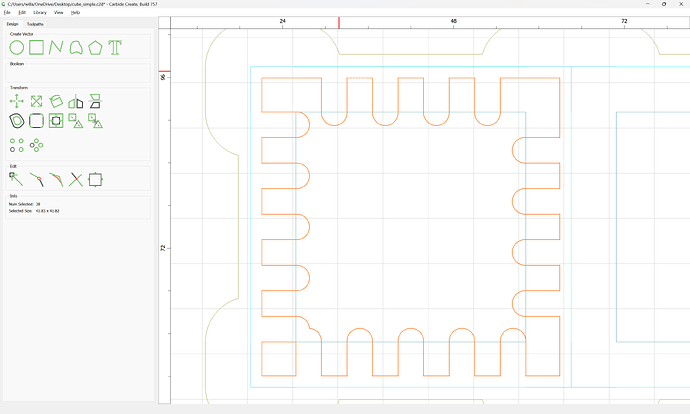

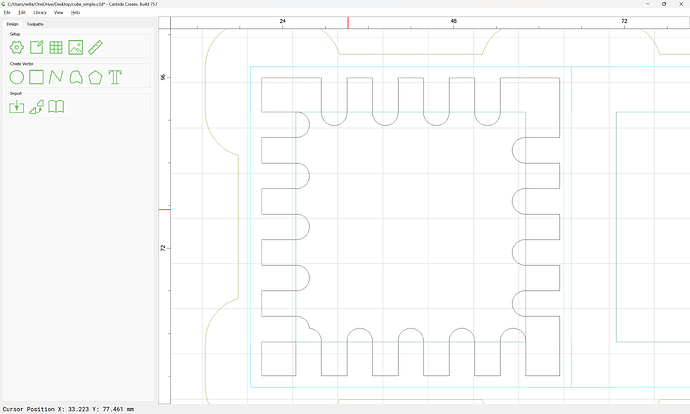

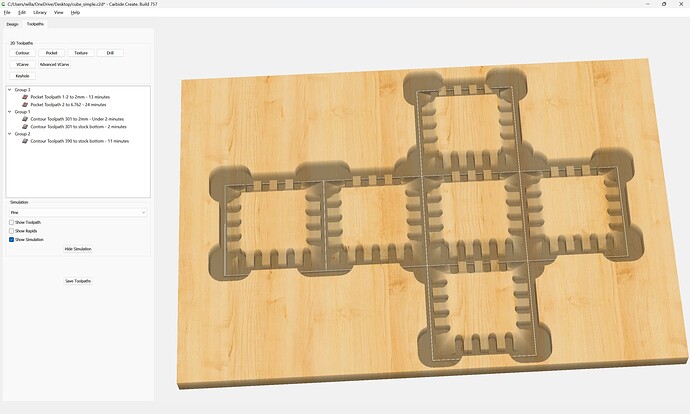

Draw up the geometry of the box:

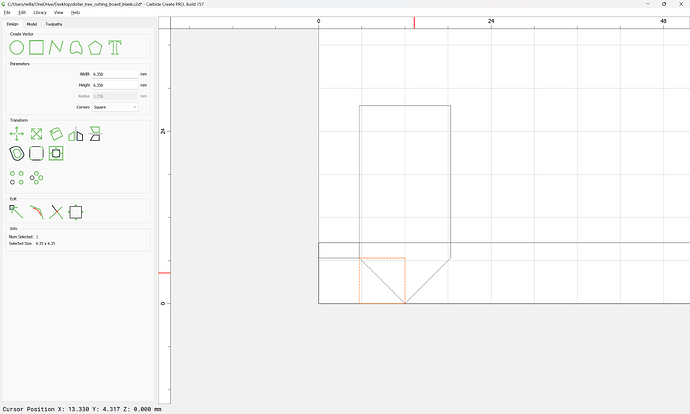

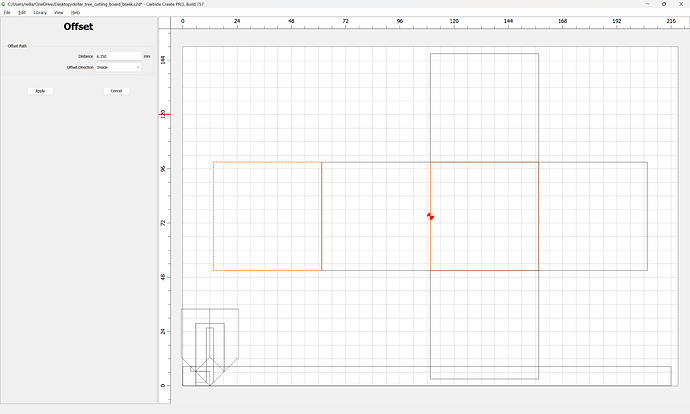

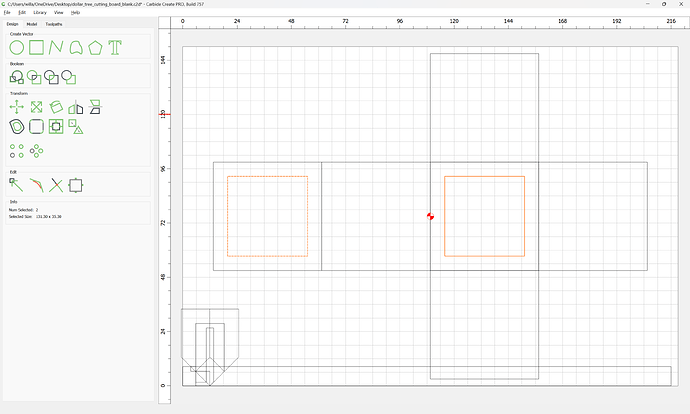

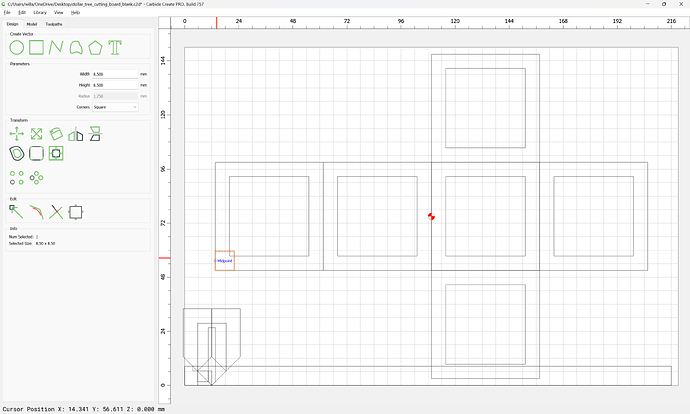

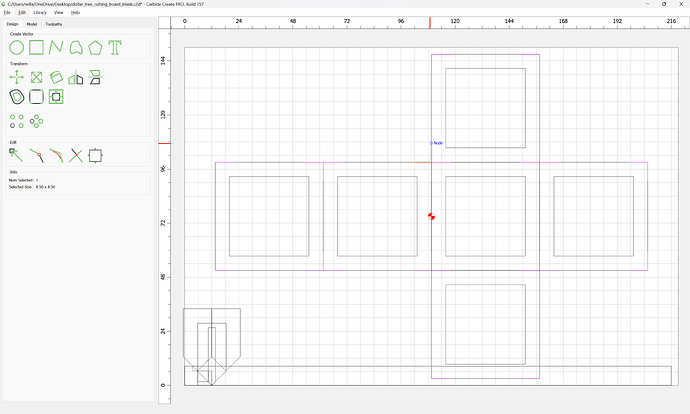

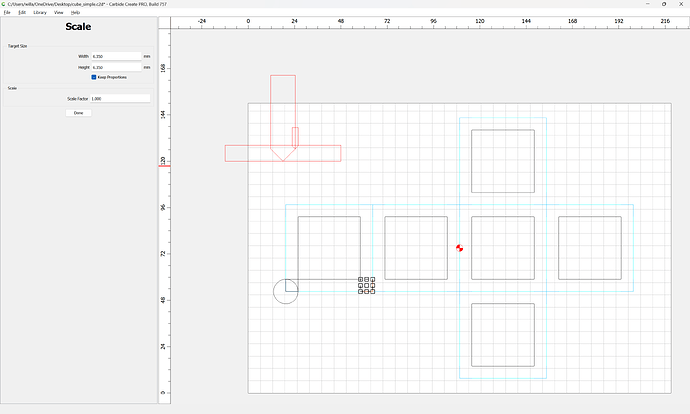

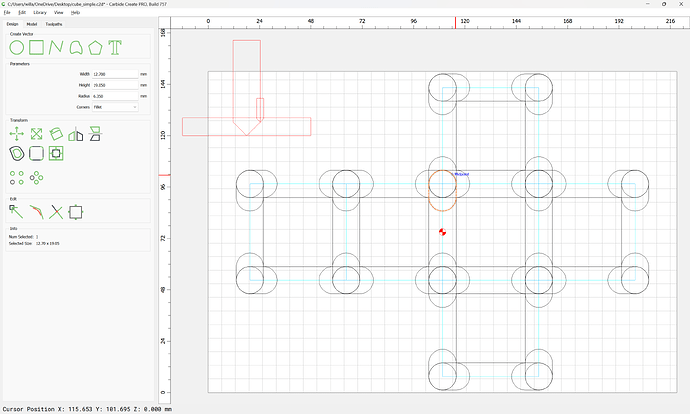

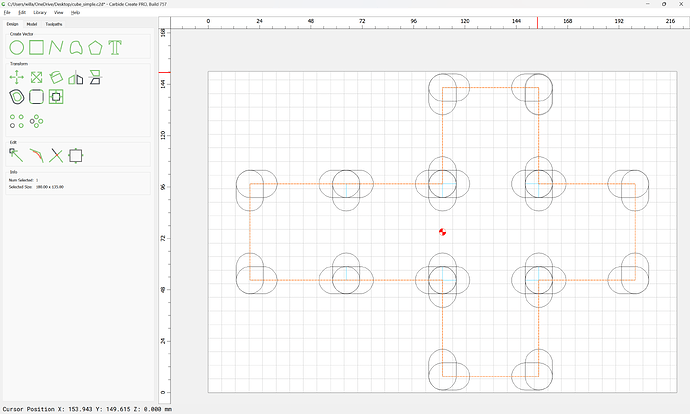

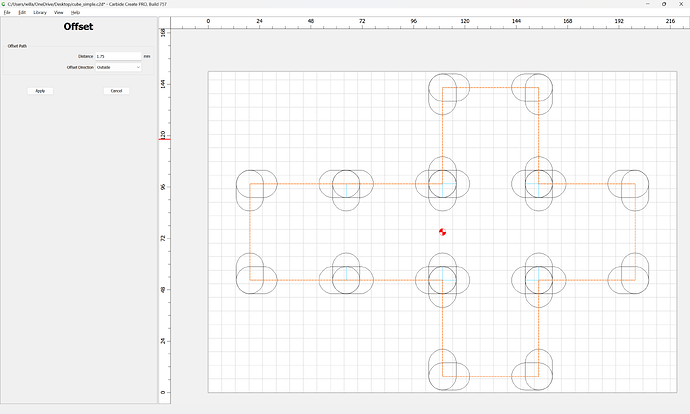

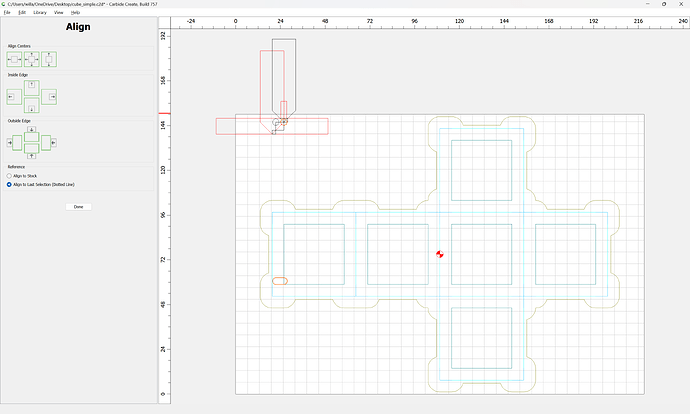

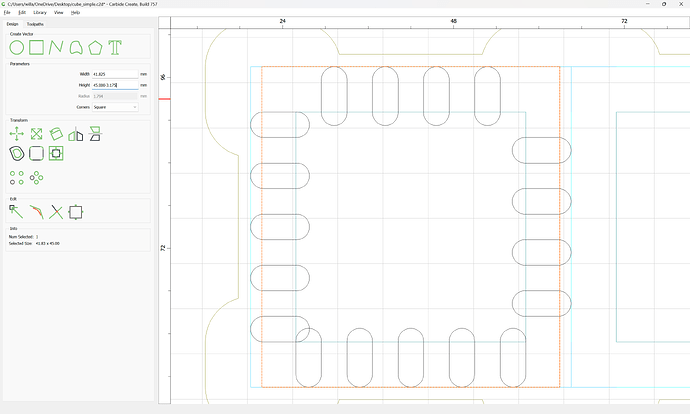

and inset each part by the radius of the large V tool:

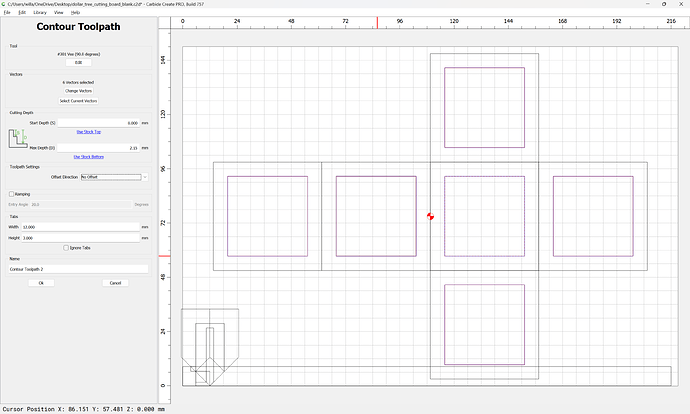

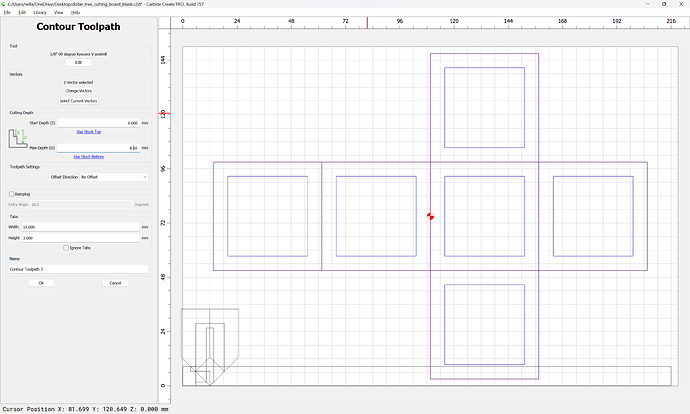

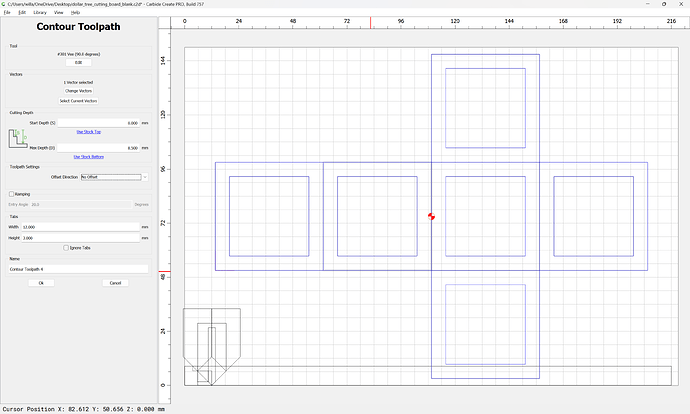

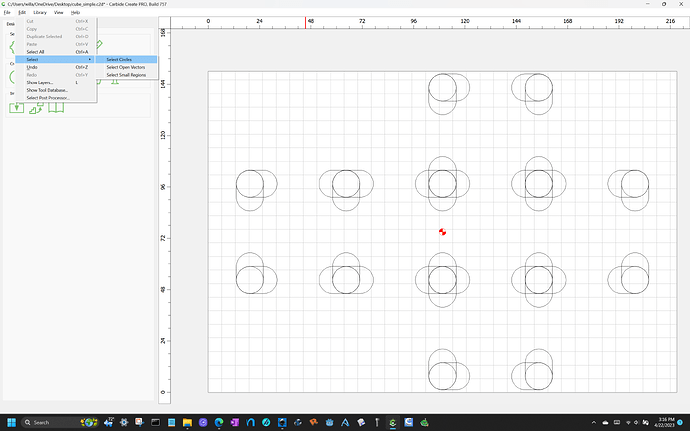

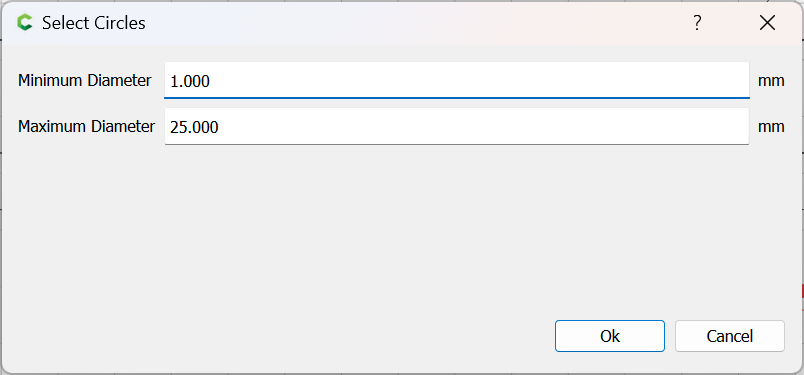

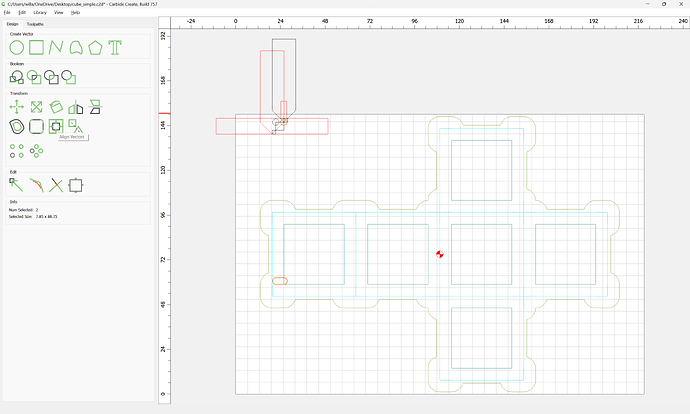

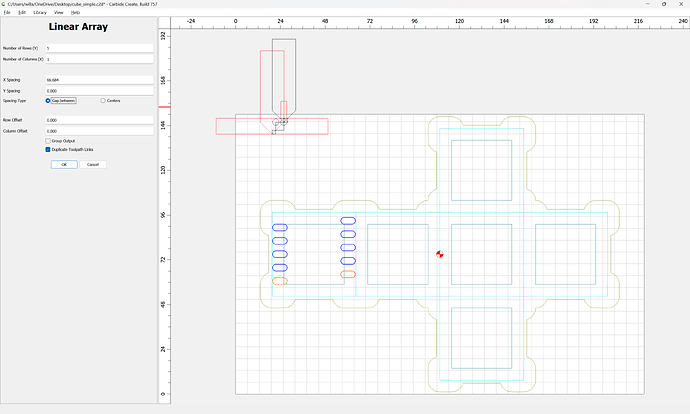

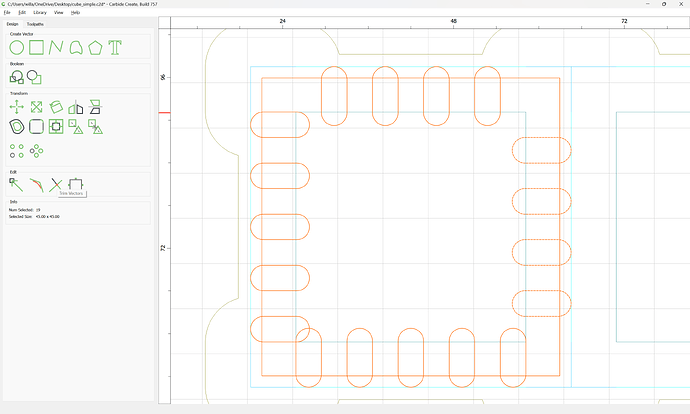

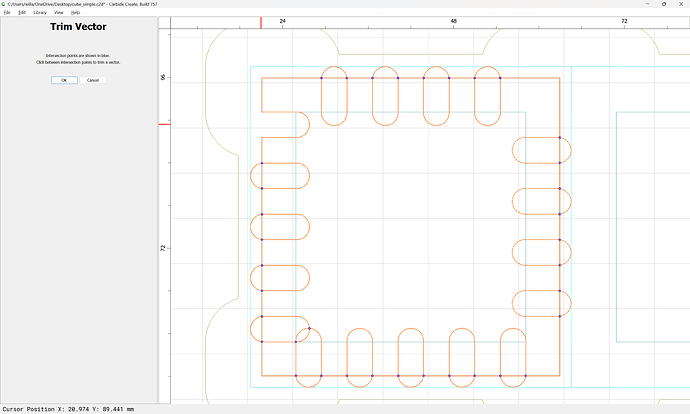

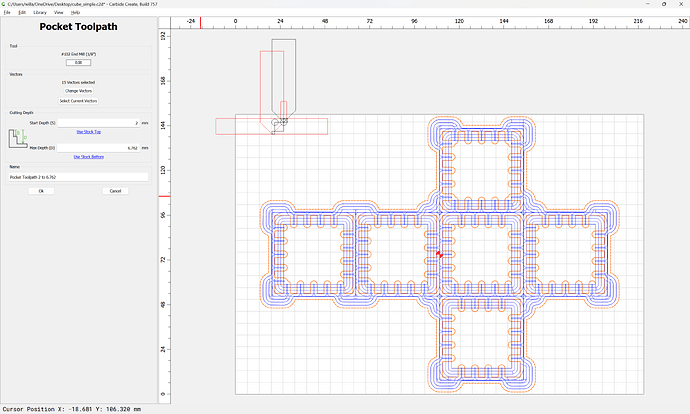

Select all the inset geometry and assign a no-offset contour toolpath to the requisite depth w/ the large V tool: