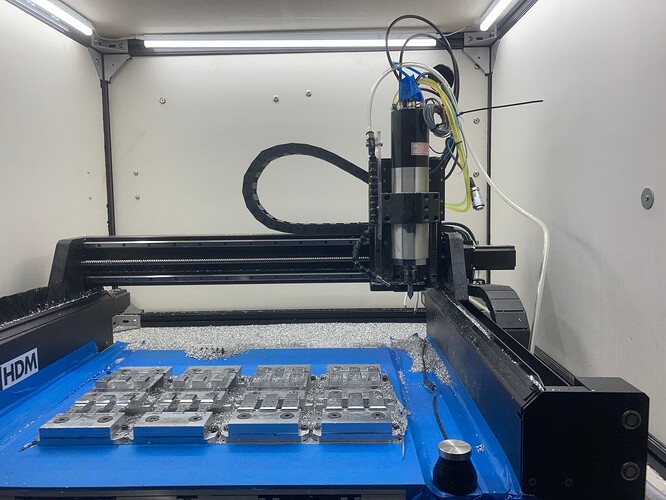

So after endless saving it’s time to start my ATC journey with my HDM.

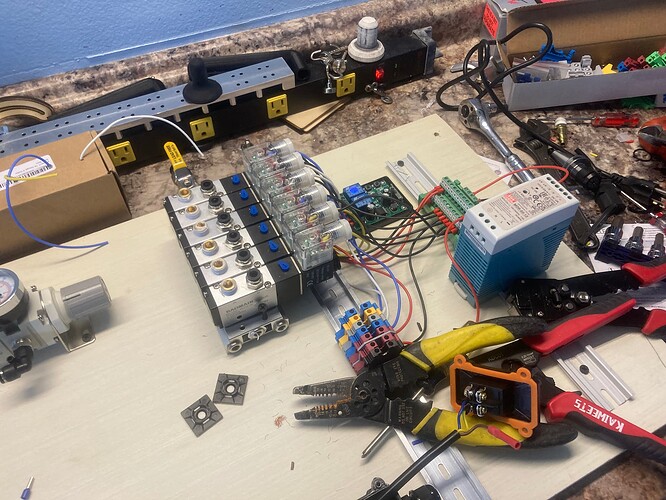

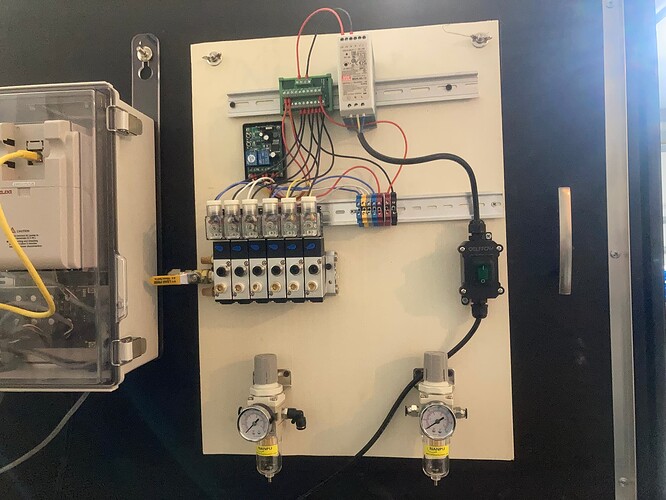

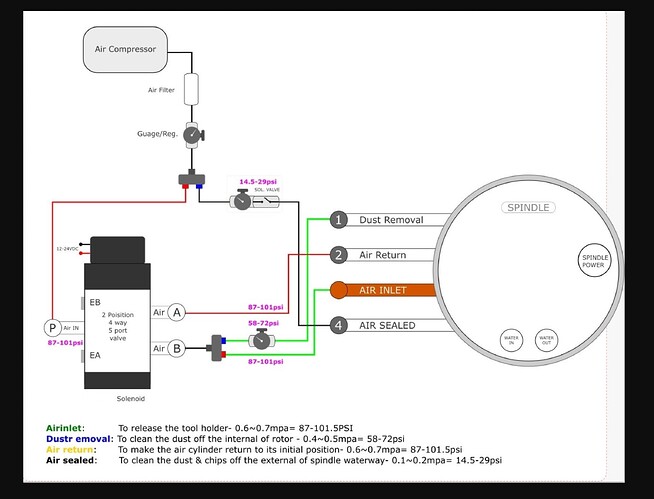

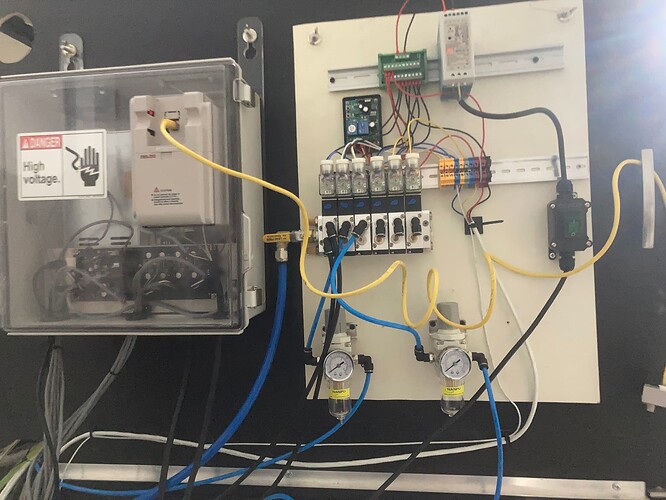

I went with the Jgl 80 2.2kw 24k spindle and I am currently working out my solenoid control for the 4 different air lines this spindle requires.

To start I will be using the stock HDM electronics with a manual tool release setup provided the stock VFD amperage can be adjusted down to 6 amps. All the other settings match the factory 2.2kw Carbide spindle. I don’t know if that setting is locked as I haven’t tried changing any VFD settings yet.

I do have a new PWNCNC 2.2kw VFD for my future Masso upgrade I can use if I have to but it’s programmed for Masso and don’t want to hook it up to the Carbide board and change it’s settings unless I have to.

For controlling the 2 main tool change air valves I went with a 12v remote control momentary relay board and modified the remote to be sip and puff controlled. This way I can easily trigger the air release while removing and inserting various tools with my limited hand function in a safer manner.

I will be running the air valve remote control board power through the VFD relay set so the spindle must be at 0 rpm before the relay will supply power to the RF board. This way a tool release valve can’t be triggered when the spindle is rotating by mistake.

I plan to use the other pin on the VFD relay to power the dust seal air valve so when the spindle is rotating the dust seal is triggered or I will just have a latching power switch for it

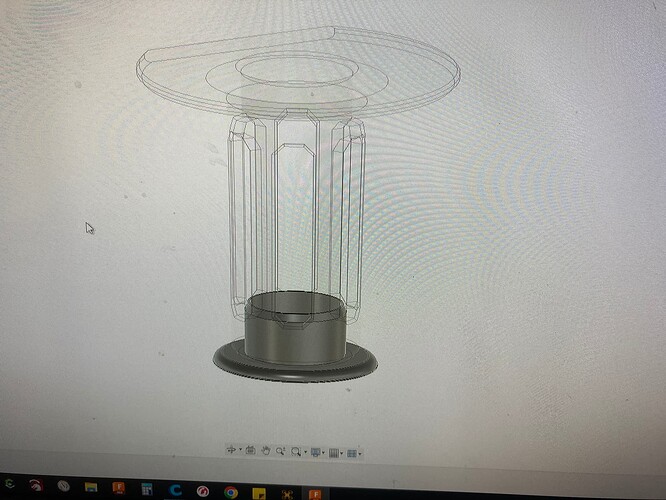

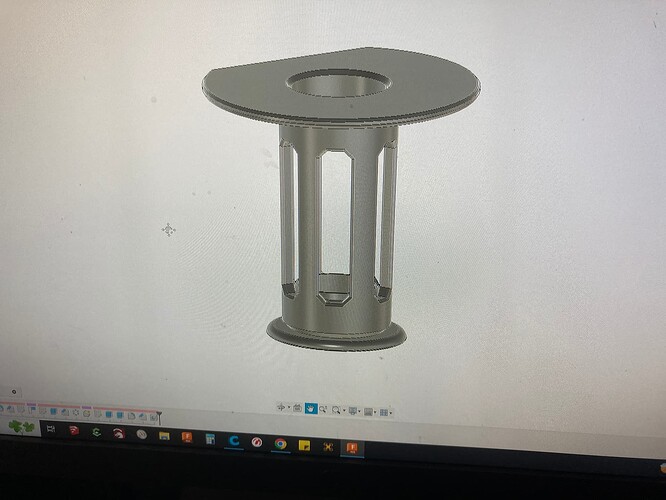

I also designed a pistol grip style ISO20 tool holder to help me swap tools and help keep me from possibly cutting myself during tool changes. The no finger function thing makes dropping and chipping tools very easy and I hope this helps reduce that. Especially with the extra weight of the tool holders I will need something to help me hang on to these spinning blades of death.

I will be bench testing the air valves this week with a small 12v battery if all goes well it will be powered by a 12v 5a Meanwell supply