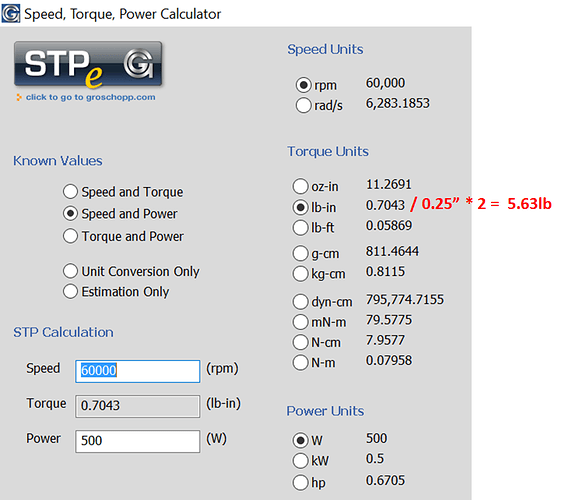

He must of been referring to his 60,000 RPM spindle with a 1/4" endmill.

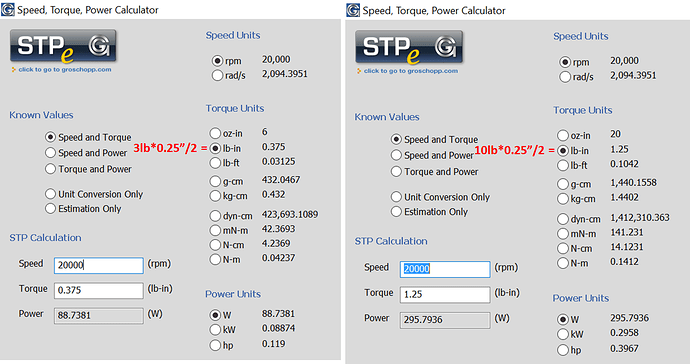

If I remember correctly, he said that his modified Nomad “likes” 3lb cutting force, and he seems to be setting 10lb as the maximum machine force in SFPF workbook. So here’s what powers are required at the recommended 20,000 RPM.