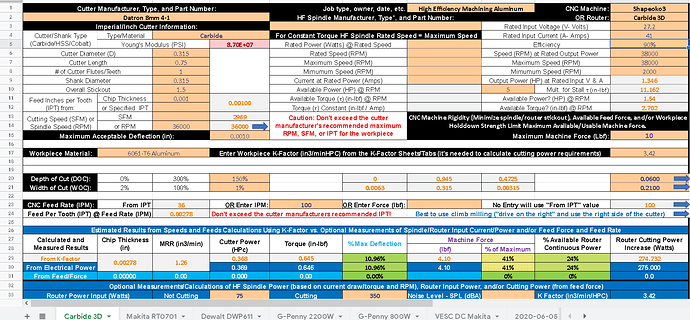

Ran max in duty cycle mode, max load ipm, lets not get into docs please. Gotta look over the log more but its impressive. With this power the Nomad is rigidity limited and it should rip on a well setup Shapeoko.

So…how much more voltage you think it can take?..