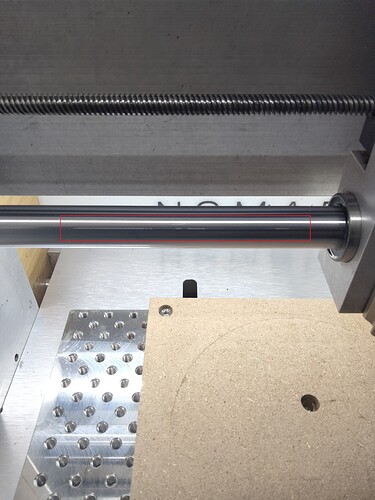

I was recently cleaning my machine after the first long job that I have run (around 8 hours total) when I noticed grooves had formed in the x-axis shafts. I recalled seeing posts from other Nomad owners about a similar issue on their machines. Since other owners had also reported grooves forming in the Y-axis shafts I figured I would check those as well… and sure enough one of the y-axis shafts on my machine has a groove that runs ~80% of it’s length. The embedded images show the groove on my machine’s shafts. It’s difficult to capture in photos, but the grooves are fairly deep - a fingernail easily catches on them. Also, there are grooves on the underside and back side of the x-axis shafts that I can feel, but are impossible to see without disassembling the machine.

I have run my machine well under 100 hours total (probably more like 50 hours) since I don’t get nearly enough time to spend on this hobby. I use a dust collection boot, clean the machine after each use and lubricate with the proper recommended oils (super lube for the x and y axes, vactra for the z). I Have cut mostly wood and acrylic, with the exception of one job that I did in thin aluminum sheet.

Since this is an issue that has been reported by others ( in one case someone had this happen to their first machine and a replacement machine - link below) I am wondering if a cause has been determined since this clearly seems like a premature failure on a critical component. My machine is probably one of the earlier ones produced - is anyone aware if there was a manufacturing defect (perhaps racking of the carriages or bearing issues?) in batches of machines that could cause this?

Lastly, what are recommended steps to fix this issue or if that is not possible make sure it doesn’t get any worse?

X-Axis grooves:

Y-axis grooves:

Here are the other posts on the same problem for reference/completeness: