I bought GWizard, because Carbide3d seems to be promoting the “CNC Cookbook” heavily and I thought it can be trusted. I now consider that a mistake. GWizard does produce “something” — you can get numbers out of it. But those are not numbers that you can take and use with your Nomad. I ended up stalling the machine or burning/melting stock on various occasions. Also, there is a “tortoise/hare” slider which I have no idea how to set, it will take your numbers into ridiculous ranges on both ends.

I have no idea why Carbide3d promotes this tool, in my opinion it is useless with a Nomad.

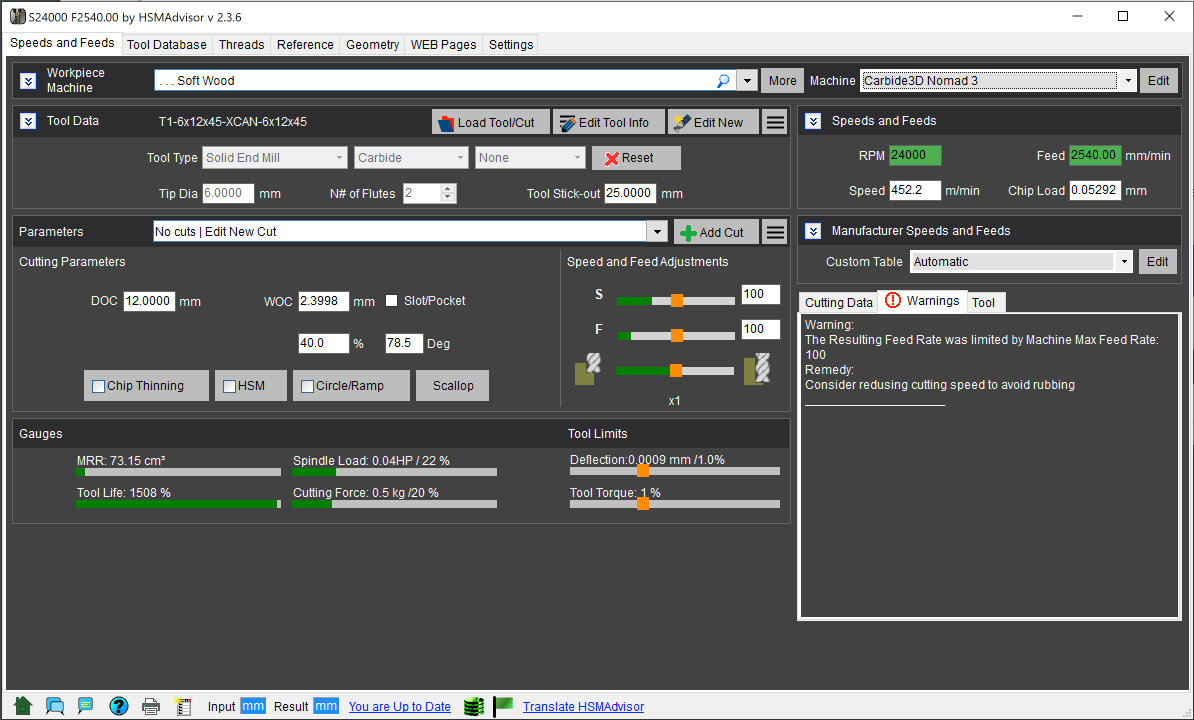

I then started testing HSMAdvisor and after loading a power profile created by someone for the Nomad, got considerably better results. The numbers you’ll get are at least in a reasonable ballpark, and for some materials and endmills are very close to what I found by experimentation. But I don’t feel like I can trust this app. I found it is overly sensitive to tool stickout and will produce good numbers for longer tools, but go over the top with shorter ones. Tweaking the “aggressiveness” slider often produces no change in feeds/speeds. It also sometimes produced numbers that I know are way too aggressive and will stall the Nomad. I tried fiddling with the power envelope, which didn’t change things much, making the torque several times smaller did make the numbers more reasonable. I ran out of time, but I intend to go back and try talking to the author and reporting my results, perhaps things can be improved.

I do believe that HSMadvisor is the better tool. Even its materials selection is more reasonable: I really don’t need to choose from 54 kinds of pine wood, but I do want to see acrylic (cast and extruded) and epoxy or polyurethane modeling board, preferably in several densities.

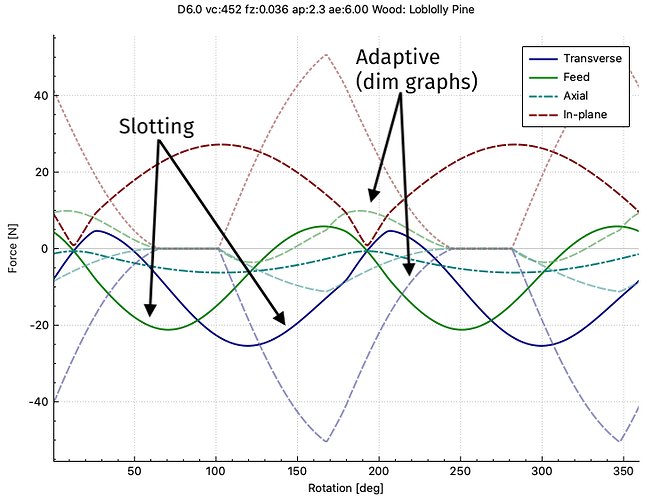

More generally, this is far from what I expected from these tools! I wish Carbide3d would dedicate some time to work closely with the author of HSMAdvisor to produce a good “Nomad 3” profile that would reliably produce usable numbers. I think this is a major stumbling block, and not just for beginners — even people who get experienced with some materials need to start from scratch with others. And if you nail down your feeds/speeds for a specific endmill in a specific material with an adaptive toolpath, you will still stall the machine in a slot.

I know that some people think this can’t be done — but I really don’t think this is rocket science. Given a well-specified machine, perfectly described endmills, and a range of reasonable materials, these tools should really be able to produce conservative numbers for us, numbers that we can use right away, with no voodoo or hand-waving. The tools should also “know” that wood will burn and acrylic will melt and not suggest feeds/speeds when this is certain to happen.

Also, I will take issue with this:

On a Nomad, I would think you don’t really need (or could justify the cost of) a paid calculator anyway?

Having paid 3k for a Nomad, why not pay $50 for a calculator? It makes perfect sense! Especially if you work with smaller endmills and risk breaking a $25 endmill. The reasons for using the calculator are different with the Nomad: it’s not to optimize mass production, but to get a good starting point in a new material with a new setup. But the cost is very much justified. Or would be, if the tools actually worked.