So I’m starting a new project, which will be the largest piece I ever did. There’s a wall in my living room that still has dangling wires from where a sconce used to be (and the former owner of the house took it with him), and I’ve had enough of sconces for a while (if you know, you know). So this time I’ll try something that’s half a decorative panel, half a wall light. Or something like that.

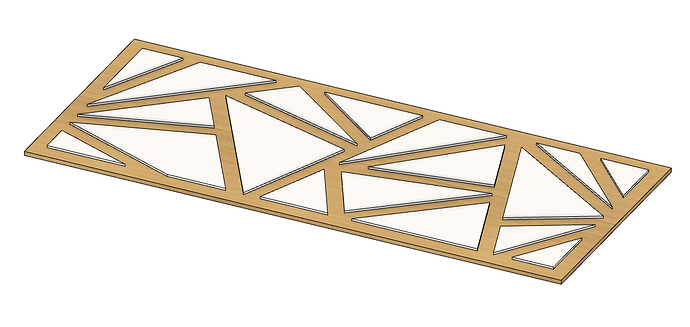

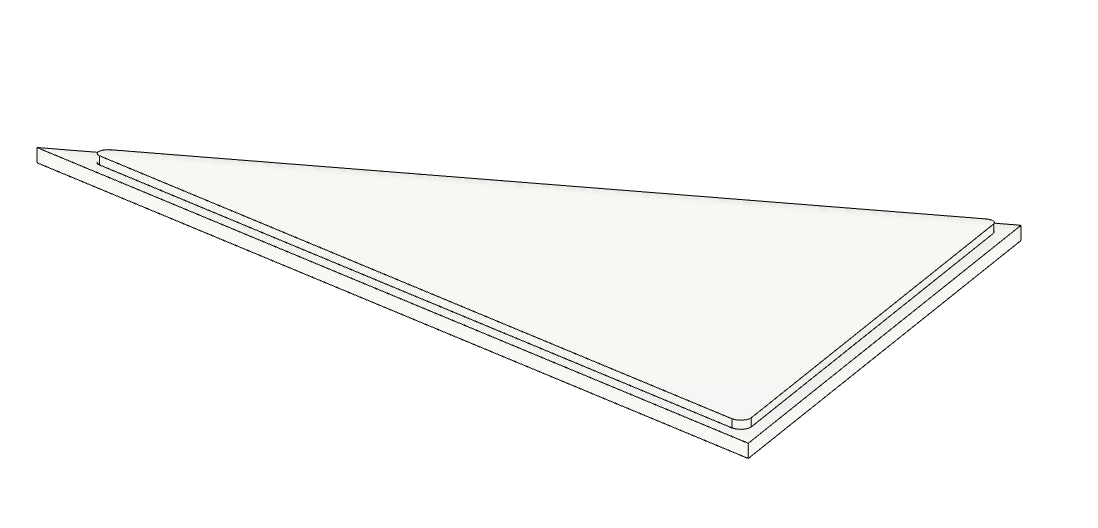

At this point it should look something like this:

Wood backing, and translucent acrylic/epoxy triangles that will be backlit.

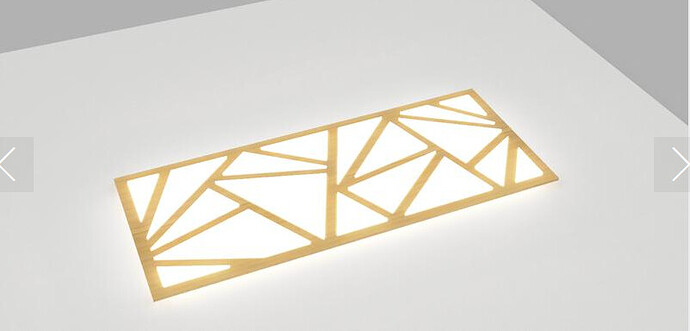

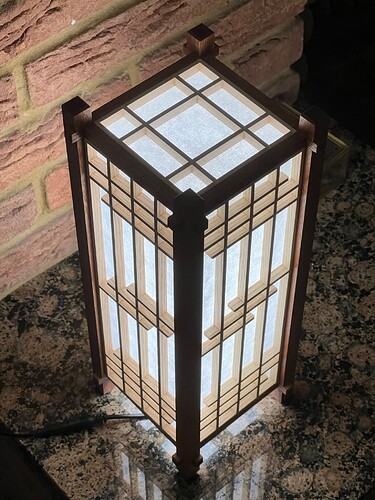

Like this, just a million times darker (the initial render had the light emission factor cranked up too much)

This is 51" x 21", so I soon realized:

- that it was going to be difficult and/or costly to find a single piece of wood that size

- that if I did, it would weigh a ton. Unless it’s very thin. Which is impossible to find in such large dimensions.

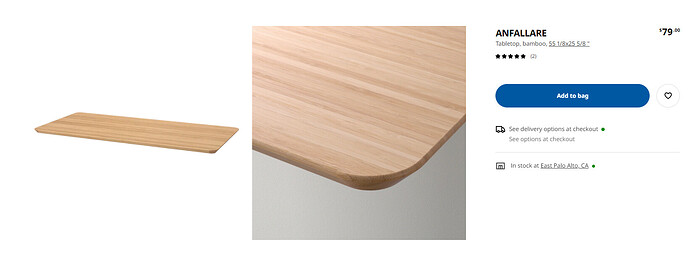

- that a giant panel of oak on the wall may not look right anyway, and that bamboo would give it a more modern and low-key appearance

And then I remembered that we recently bought a tabletop at Ikea, that checks all the boxes: it’s slightly larger than I need, it’s bamboo, it’s surprisingly light, and it’s probably the minimum amount of money I can spend to get me a wooden surface that large.

Here’s the underside of that tabletop,

Given the weight I was sure of what was inside (paper honeycomb), and sure enough, once I cut out the back and removed it: honeycomb.

Removing it (and the wooden supports) gives me access to the full surface I want to mill:

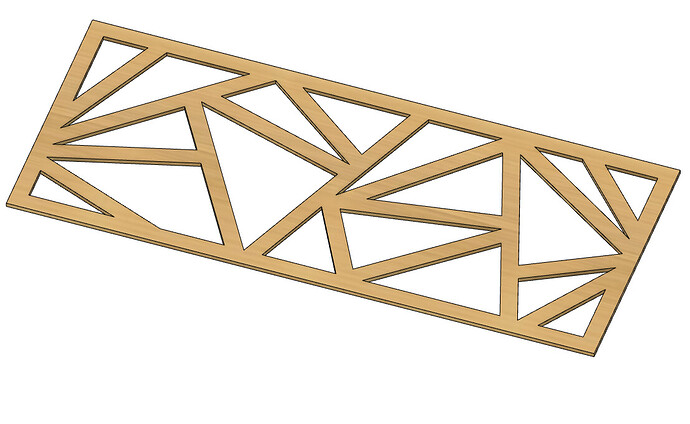

Next step: cutting openings for the acrylic/epoxy:

Each triangle will have a raised part above the bamboo backing, and a part that sits in the openings

Since I don’t know where to get such a large sheet of translucent acrylic (without having to sell a kidney either), I’ll probably pour acrylic & white pigments again, and machine that into the final triangle shapes.

Stay tuned, mistakes and multiple iterations incoming.