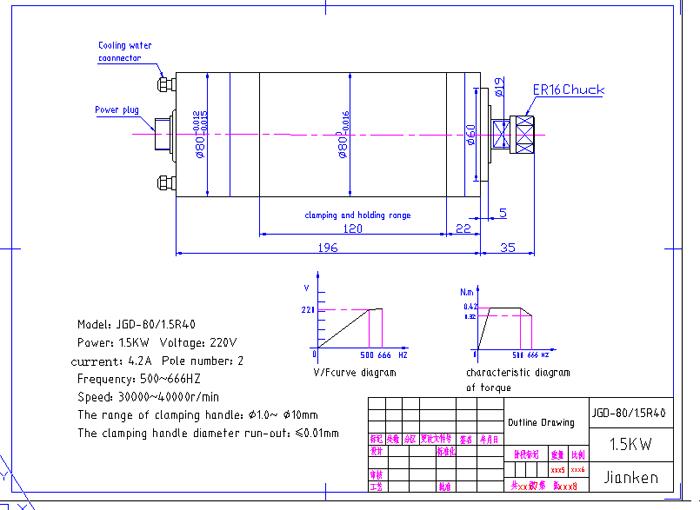

As pointed out in my comments here, Jianken’s spindle specs aren’t very realistic. For this spindle they claim 220V * 4.4A * 1.73 = 1.675kWA input produces 1.5kW output. You’ll probably need to increase the VFD drive current to about 7A to get that level of power output. (See what Jianken and/or the motor label says?) How much did you have to pay for it and shipping/fees - to where?

According to this unit horsepower for aluminum decreases from 0.3 to 0.2 HP/(cubic inches/min) when cutting speed is increased from 3000 to 5000 SFM at 0.005 IPT/Revolution chipload. It levels off after that, but he could only test to 25,000 RPM with that 1 inch diameter 2 flute MSS endmill cutting 7075-T6 with Cimcool.