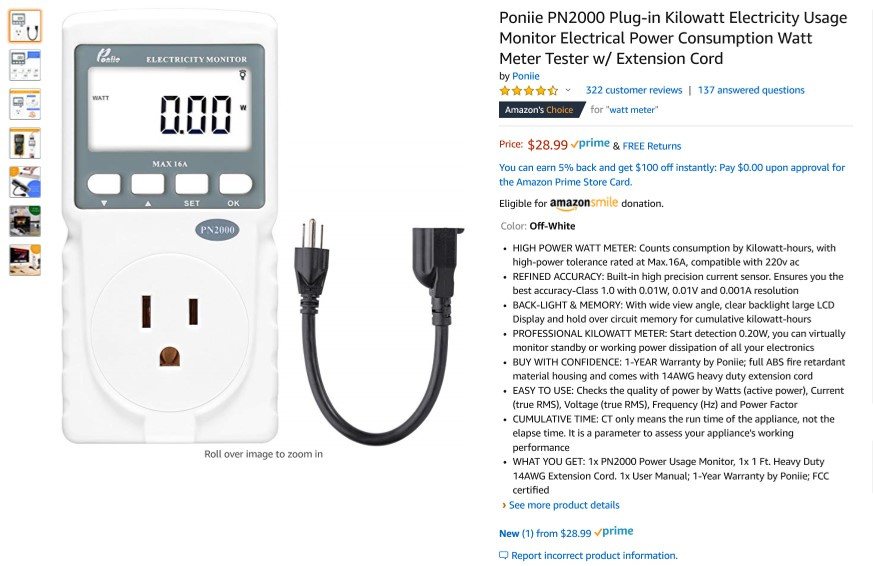

Maybe keeping track of machine and/or spindle cumulative run times with something like this would help?

That device also measures router input power which can also be useful.

Also, maybe Gates’ newer GT3 belts are better than their predecessors? Is everyone using/evaluating Gates (vs Chinese) GT2 belts?