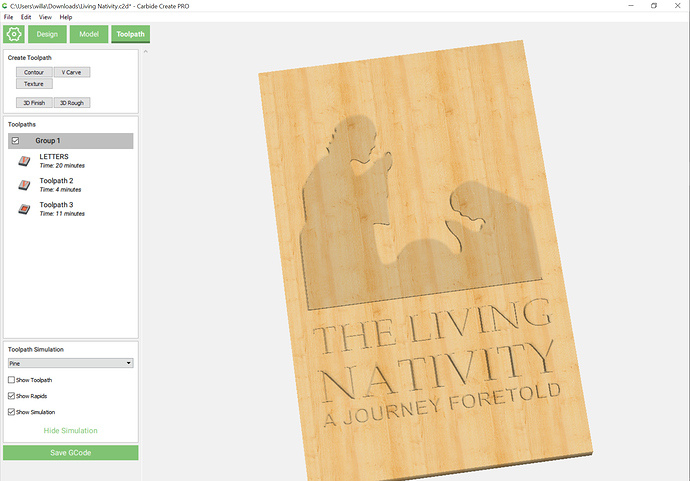

Which do you want raised? The image and text or the surrounding area?

If you want the image and text to be lower that should be easy, pocket the image, and do a V carving of the text. Optionally you could inset the image twice, cut the original and second inset as a V carving, and the first inset as a pocket:

See: V carve + inside pocket? for details

Living Nativity_INSET.c2d (1.7 MB) (I’m afraid I didn’t have the font you used and had to change it)

If you want the other way around, just add a rectangle around things and offset to the outside twice and assign appropriate toolpaths. See: https://wiki.shapeoko.com/index.php/Carbide_Create_Basics#Clearing_area_around_drawing