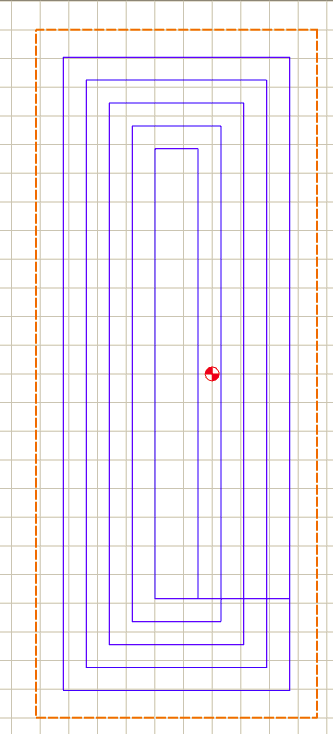

I have noticed that sometimes CC uses the wrong step-over (too large) for the second pass when doing a pocket. All the other passes are right. I haven’t spent the time to chase it down, but it’s clear even on the preview that the first step-over is larger than the rest.

EDIT - yes, CC is using the wrong step-over for the first step-over. This is a 3/4" bit, 8mm stepover. Grid is 10mm.