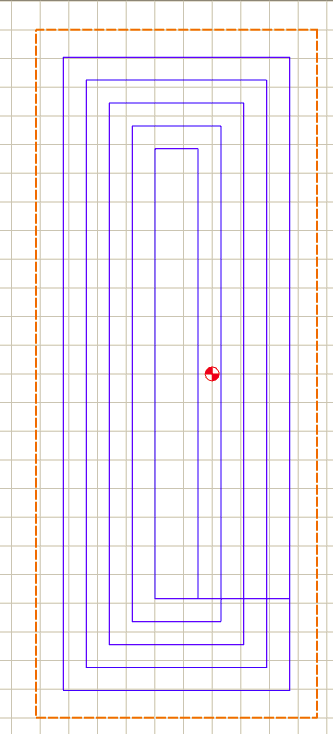

Hello, I am doing my first catch all tray and I’m using a 7/16 inch bowl and tray bit. The problem is it’s leaving a small sliver of material (about the thickness of a toothpick) in the middle of the carving. How do I fix this? Thank you…

The best thing you can do is post your C2D file. We could just keep asking you for this or that screenshot, but the C2D file has everything we need to know about your setup.

Several people have reported small walls left behind in pocketing. There appears to be a bug in the software. The long term fix is from C3D but short term decrease your step over to slightly less than 50% and it will likely fix your problem. If the project is still in place just do a full depth doc to clean up with the step over changed. If you have already removed the project then sand paper may be the only answer. However for future projects try the decreased step over.

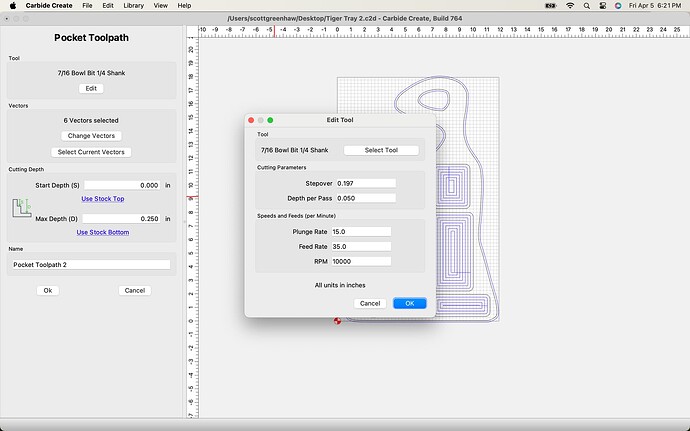

What is your stopover?

Does the 3D preview show this?

Is your tool diameter accurate? How have you entered the tool?

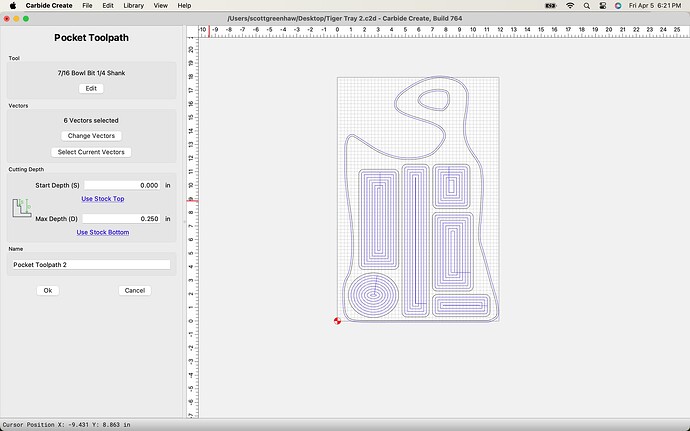

Yes I did measure it and entered it in my tools. I even double checked the measurements. My step over was 20% and after I saw what was happening I changed it to 15% but still doing the same thing. Also no 3D preview doesn’t show this.

I still have it loaded. I figured I would get some good advice on how to fix this so I left it. Thanks

How did you model the bit? Is the uncarved material full height or does it follow the curve of the bit?

It sure on what you mean by model the bit. I am still very new and only know enough to get me in trouble.

Yes the material is being left from the top all the way down.

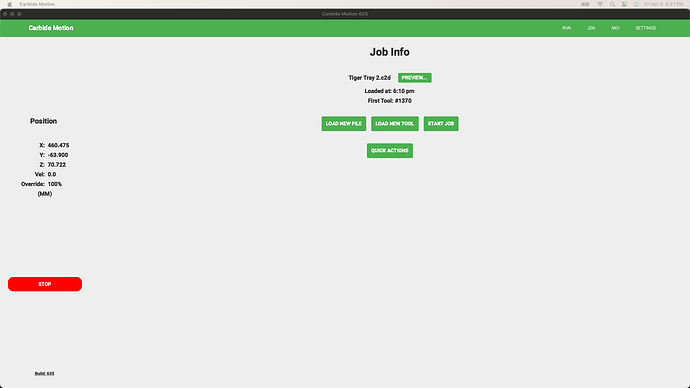

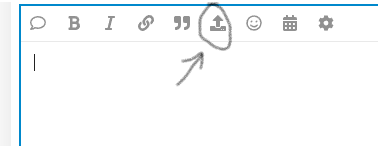

This is the best way for the community to help find a solution to your problem. ![]()

Ok my apologies, what is a c2d file?

CC doesn’t know bowl bits; you would probably choose a straight bit or a round bit. If you chose a straight bit I would expect a concave sided peak in the center of a pocket.

I did put it under an end mill.

It’s your Carbide Create File.

That you saved.

It doesn’t matter how you enter the bit, as an endmill or ballmill. It won’t display correctly in simulation either way. But you should get a valid toolpath. CC only uses the diameter for 2D paths, it doesn’t consider the corner geometry. You need to make sure the stepover is less than the flat bottom of the tool, and in this case a little less than the radius of the tool.

The problem with the leftover material in the middle is as Guy suggested. When you use a stepover exactly half of the tool diameter, sometimes CC thinks it doesn’t need to make that initial center pass.

Lower the stepover just a smidge below half the diameter, and it should work OK.

I agree, the step over should be less than the flat part of the bit, but you can still have a problem in the middle if the diameter overlaps but the flat part doesn’t.

I started at 20% then went to 15% to try to correct it. Sounds like I went the wrong way. I am heading down there soon and will let yall know. I will also try and upload some pics and files. Thanks for all the advice.

I have noticed that sometimes CC uses the wrong step-over (too large) for the second pass when doing a pocket. All the other passes are right. I haven’t spent the time to chase it down, but it’s clear even on the preview that the first step-over is larger than the rest.

EDIT - yes, CC is using the wrong step-over for the first step-over. This is a 3/4" bit, 8mm stepover. Grid is 10mm.

I increased the step over to 45% and hade the same results. I did reload the file so the change would take affect. I am using a piece of plywood for my test piece.

I think you are running into the bug I just reported. The bit is using a too-great stepover for the first pass, since the bit isn’t flat all the way across you get this material left behind by the radiused area of the bit.

There’s not much you can do about it, this is a bug in CC. The only workaround would be to make the stepover so small that even when the larger value was used, it was still in the flat part of the bit. I suspect the greatest error is double the requested stepover, so a stepover less than half the width of the flat portion of the bit.

What is the smallest step-over you have tried?

Lets say your pocket is 1/4" deep. I would do a rough pass first at 50% stepover starting depth at 0.00 and finishing depth at .23". Then a finishing pass with a 10% stepover; starting depth at .23" and finishing depth of .25". This is what I do when I use a bowl bit for any of my jobs and it should give you a fairly clean base.