3000mm/min

20k RPM

1/4in 2 flute up cut

Results were worse than the first. Also it looks like it was more like 23k RPM from the ODrive data. Still need to tune that.

3000mm/min

20k RPM

1/4in 2 flute up cut

Results were worse than the first. Also it looks like it was more like 23k RPM from the ODrive data. Still need to tune that.

Did it get melty on you? What depth?

Drop the speed to like 10-12k.

It isn’t quite melting it. But it is just pushing up a MASSIVE burr instead of cutting the plastic even at 10k.

So I just pulled the burr away and the surface finish at the bottom of the pocket is not that bad. Starting to think that these cheap cutting boards I got are not HDPE.

How sharp is your cutter ? a semi-blunt one mess up a cut even when feeds and speeds are in the right ballpark.

I’m with @neilferreri on the speed: 3000mm/min at 20k runs fine on a single flute, so for a two-flute you still have a x2 margin (depending on the DOC you are using that is). Since you can’t (or at least may not be willing to) push the feedrate much higher, then drop the RPMs to 10k indeed to double that chipload.

My personal guideline for chipload in HDPE is 0.004’’–0.01’’, and currently you are at 0.003" (which can work…if you are using a sharp tool. But better get back in the comfort zone anyway?)

Agree that chipload can go up - 0.005” (0.127mm) on HDPE here. Less rub more bite.

The cutter is a fairly new. I’ve used it twice to cut Oak. It was cheap though so might not have come particularly sharp. I do have some single flute 1/8in end mills that I have never used if those would work better.

Also with the ODrive I can run this router as slow as 800 RPM. Below that and the RPMs are jumping all over the place. That may get better with tuning though. I do not want to run that slow for long periods of time though as the cooling fan also runs at that speed. I think 2000 RPM would be a good spot for minimum RPM for long periods of time. In other words I can go slower. LOL

single flutes rock, especially for plastics where good chip evacuation goes a long way to get a good cut, so if you have some of those definitely try them instead.

I don’t think you need to go much below 10.000RPM though, certainly not below 5000RPM.

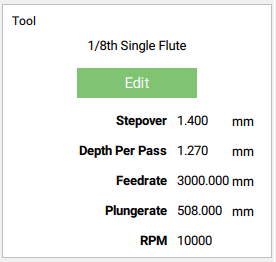

So what would be a good single flute 1/8in recipe then?

I run my router around 18k, simply because it sounds nice and consistent there. For HDPE, my minimum chipload is .004” outside of corners. Stock Shapeoko with plastic specific, uncoated, single flute endmill. .25” diameter cutter clears chips nicely. For DOC, I don’t pay much mind on roughing passes. I use simple user defined defaults like 25% of cutter, 50% of cutter ect.

My cutter manufacture(Onsrud) did suggest to me the use of 10krpm, slow as possible. Material supplier (King) suggested much much higher, 20k+ or so if I recall. They use Onsrud cutters. End of the day, doesn’t make much difference on my stock Shapeoko.

I really enjoy reading this thread. Thank you for your contributions.

So with the above settings the burr is much smaller. I am getting strings though not really chips and the bottom surface finish… fluffy?

Interesting. I’ll do (or find in my archive) a test cut in HDPE on my machine later today and we can compare cuts. I could not tell proper HDPE from another kind of similarly-looking soft plastic, but it should not matter much.

In the meantime here’s an old random example I documented that produced snow flakes:

https://shapeokoenthusiasts.gitbook.io/shapeoko-cnc-a-to-z/cutting-plastics#hdpe

(this was slower than it need to be, so at twice that speed you should be all good)

Can you share the file itself ? (just so I use the same geometry, total depth, etc…)

It is just a 40mm x 40mm square pocket with a depth of 3mm. Nothing fancy at all. This is just for testing and tuning the ODrive, but at the same time I want to tune using an ideal set of settings.

Got it, I have some HDPE on hand, I’ll test that and report.

Here’s my test using a (sharp) single flute 1/8" endmill, same settings you posted.

(I turned off dust collection after the first pass to see the chips)

So I’m not sure what is going on in your case. Less-than-sharp cutter maybe, or the material being some new kind of unmachinable thing that is even softer…

Can you take a pic of your 1/8" cutter, out of curiosity ?

My best guess is that this is some other form of polyethylene

Could it be UHMW ?

As I said I don’t know the first thing about the various families of plastics, but I stumbled upon this guy’s statement :

"UHMW, melts like a fine swiss chocolate, slightly above body temperature… or so it seems, soft and gushy, I think its worse than teflon.

Low speed, tons of juice and pretty much feed it as hard as Gzero goes, or your tools have clearance for."

That’s in line with the next test I was about to propose: 5000RPM at 1500mm/min (and then bump that up with feedoverride during the cut up to 3000mm/min if needed and if the machine does not complain), i.e. same chipload but at a lower SFM, which in theory should help keeping the heat down and prevent the semi-melting that produces the fluffy bottom/stringy chips.

Or just pick a better-suited material for your tests

Its not actually melting at this point. The chips are just not break.

After those changes I am getting more chips but still long ribbons on unbroken chips. I think I am just going to try with some wood instead.