Are you sure? The data suggests otherwise. Was it sensorless?

Positive, and yes sensorless.

I actually couldn’t get it to run a successful detection in BLDC son I’ve only ran it FOC

Then there must be a problem with your VESC data logging!

I reviewed the log on my tool without issue, what’s the problem you’re seeing?

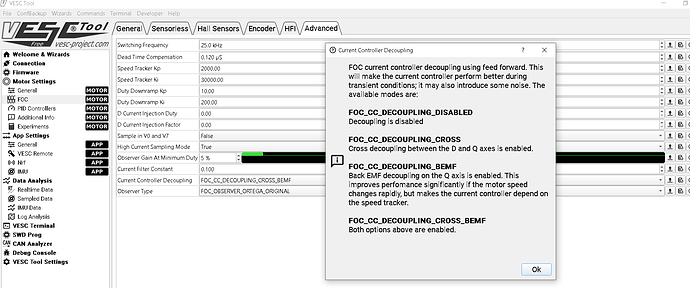

d and q axis currents and voltages are always 0. Maybe your VESC doesn’t support FOC?

more likely is that the firmware is not logging those values correctly.

Looking at the design of the spindle I would actually suggest using a different motor all together. For instance this guy:

It has two pole pairs so it could reach 30k RPM. It is 2200kV so it could easily do that under 24V. You could change the gearing however you see fit. I would probably go for a 1.5 to 1 or even lower.

To make it would the motor would need to hang off the front instead of the stock location. If only you had a way to machine a custom bracket to hold it.

Isn’t the special thing about router / milling spindles the large shaft, multiple bearings for sustained axial & radial load and a chuck on the front?

How would we add those onto a regular brushless?

With the Nomad stock spindle you do not have to. The drive shaft already has all that. The motor is decoupled from the spindle.

If we’re talking motor replacements, I think I’d rather find something that fits within the same height profile as the existing motor. A motor like that should be much easier to integrate.

Replacing the motor is becoming increasingly appealing though, especially considering the Nomad 3 is going to have an upgrade.

Well that makes life easier then

IMO it’s more likely that the VESC can’t run FOC sensorless that fast. @Vince.Fab - Reduce speed to a minimum with no load and see if d and q axis currents and voltages show up in the logfile?

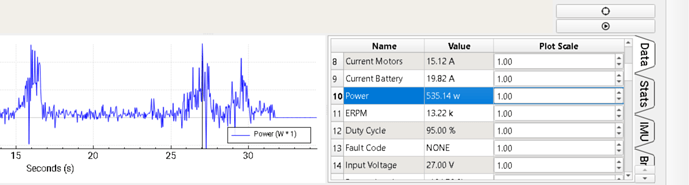

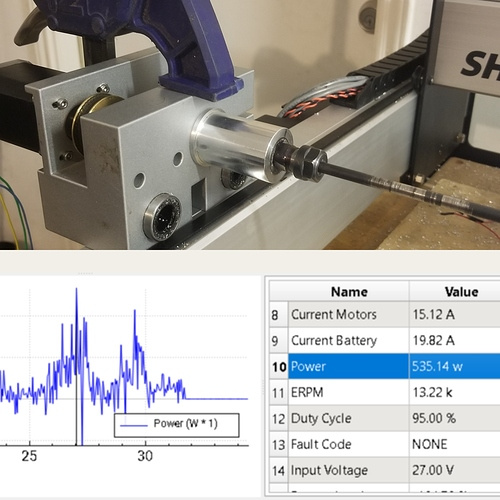

Maybe this will mean something?

And I am running ancient hardware so who knows. The main thing is that it is working.

Here is a CSV of it running in manual speed control mode to target rpm. PID is definitely the way to go.

Data now shows d and q currents - so apparently running FOC now.

@Vince.Fab what does the VESC report as Kv for that stock Nomad motor?

I don’t think it will tell me the kv directly but if I use a formula it comes out like this.

19500 (max unloaded erpm) / 0.95 (duty cycle) / 4 pole pairs / 27 volts = 190Kv?

From your other post, it looks like 13220/4/27 = 122.4 RPM/V

That was loaded and 190 was unloaded which I read kv should be measured at.

I forgot, I meant to ask. Did you notice any extra heat from the motor when you were running at 500W?