WADR (did I make that one up?) you’re 100% wrong. Trust me or learn more about it yourself (it’s not “rocket science”), but please don’t direct Vince and others down that “rabbit hole”!

Vince, Griff

Please don’t give up on your efforts. As others have pointed out, the brushless Makita router is likely not as powerful as the 0701. But it may be adequate and could offer numerous other advantages.

If you tell me what the resistances of the routers’ motor windings are, I should be able to provide an estimate of their relative power capabilities. (Which you should also be able to do with your cutting tests if they’re router power limited.) That would also enable me to provide advice on powering the brushless routers.

I haven’t given up. Truth is, it works fine.

While interesting, I don’t really care how much power it requires etc etc. Just not my thing.

I’ve hogged out inch thick aluminum with a 3/8” TAS, 6mm doc. I’m currently doing full depth (1”) adaptive in red oak, no issues.

The router is not grounded as was my DeWalt. No static problems yet, humidity these past few weeks as low as 5%.

Under heavy load I can hear the router slow down a bit so the power supply may be a little light, we’ll see. If I smoke the cheap ps at some point I’ll report and maybe upgrade to a Mean Well.

The original question in the thread is answered. Thanks to @Vince.Fab.

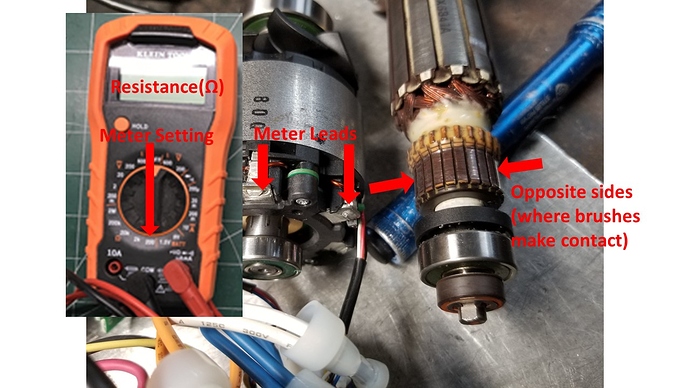

At the risk of exposing my ignorance to the derision of others, I’ve no idea how to accomplish that. This is the extent of my electrical test equipment. I’ve not yet learned how to use the inductance/capacitance meter, it’s on my ever growing list though.

Throw some hints my way and I’ll see what I can do.

Griff,

IMO derision is counter productive, but I’m not a Trump supporter!

This should help. Make sure that you have the power disconnected first! Please ask if you have any questions or concerns.

Cutting power is dictated by the characteristics of the material being cut and the volume and speed of its cutting. The axial (depth) and radial (width) of the cut along with the feed rate and material type would be really helpful to those of us interested in such things. Knowing the router speed and cutter details would also enable calculations of machine forces and chip loads. That info could be really helpful in the production of better “speeds and feeds” as well as other usage guidance for the Shapeokos.

This experiment isn’t over until we find the limits of this router! This is the only low cost option for a brushless that’s 30Krpm capable . Going to pick up a few Destiny Diamondbacks tomorrow for continued testing, they assured me the 3/8s will survive at 30k…almost $50 each.

The 360 watt power supply was enough to push 0.250 through anything I could throw at it. Hopefully the new 20amp unit i recieved today will do the trick for bigger tooling.

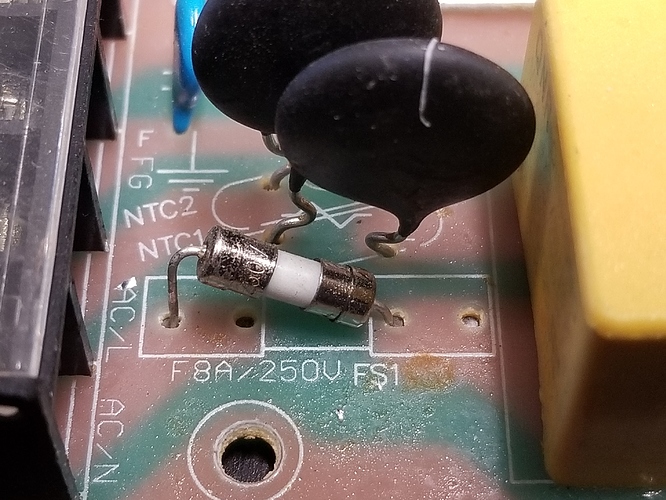

Griff, one of my cnc operator buddies always told me you want enough load to hear a difference when cutting. If you aren’t blowing that fast acting fuse I think it’s fine. Im going to find a suitable fuse holder to solder into the board just in case.

It’s interesting that neither of us have experienced the smoke and destruction predicted early in the thread  .

.

Possibly the XTR01 isn’t rated at 1.25 hp, the basis of the smoke prediction? I’ve never seen any hp rating for it.

Anyway, I’ve a few more hours on mine, albeit not pushing the limits, no issues at all.

Got some larger black walnut projects in the works, will start pushing then.

It looks like a solid option that I will likely use in future. Thanks for being pioneers for the rest of us!

A lot of predictions of smoke and death early on… that usually means you’re onto something good!

Vince,Griff

Got numbers!?

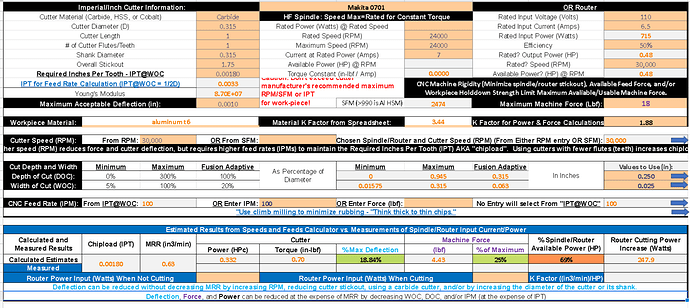

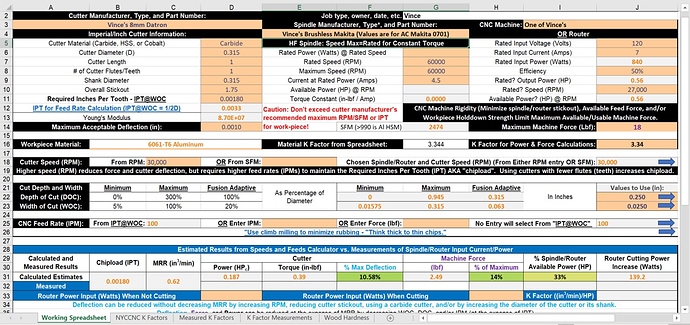

This weekend I put in the brushless and ran it pretty hard. 8mm Datron single flute

Actually stalled it when trying to cut like a corded Makita, dialed back 20ish%

Cool! Why that K factor? Thanks for using the workbook!

Good catch! Little bit of dyslexia, it’s supposed to be 3.344 for 6061 T6. Still getting comfortable with your worksheet!

Btw how close do you think that router power estimate is?

Here’s what it looks like with a 3.344 K-Factor (proportionally reduced power and force) and the latest version of the workbook. I corrected an error in the bit deflection calculation when the shank diameter exceeds the cutter diameter.

2019-08-28 Speeds and Feeds Workbook.zip (155.7 KB)

NYCCNC’s K-Factor for 6061-T6 Aluminum is lower than the 4-5 most calculators use. So it’s probably conservative (overestimates the cutting power and force requirements). Once you start using your HF Spindle you’ll be able to measure it.

It’s also pretty easy and inexpensive to build an ac power meter to use with AC routers and power supplies powering brushless motors.

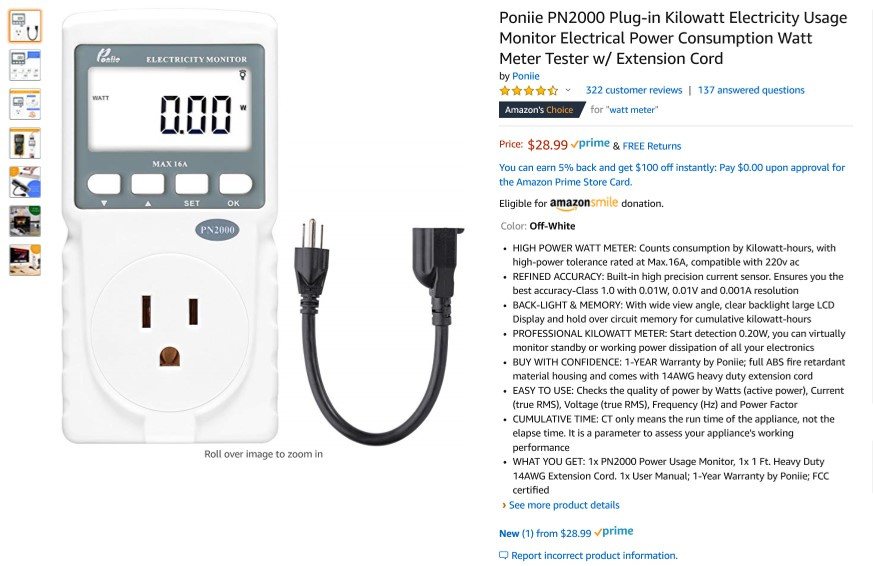

I’ve determined that this plugin power meter is almost as accurate as the ones that this guy uses, and a lot faster. For those that may be interested he has a nice description of why a meter that corrects for power factor is necessary . Measuring input power to VFDs, AC routers, or DC router power supplies with this device should be sufficiently accurate for K Factor measurements and real time cutting performance monitoring.

Well this sucks. Apparently my account and posts got wiped out when the forum server died.

Good news is I have been able to properly read the RPM sensor, so just waiting for my new ESC and power supply. Once I have that I should be able to make it so we can precisely control the spindle speed.

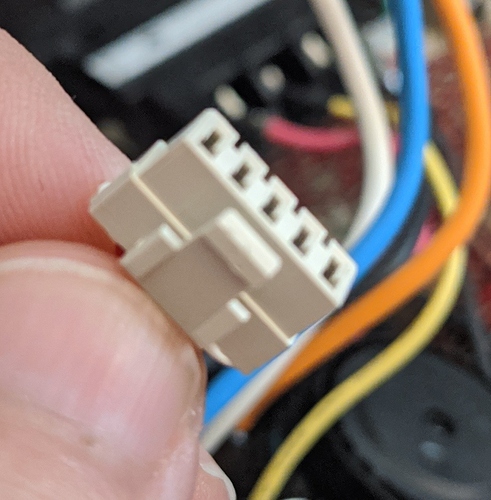

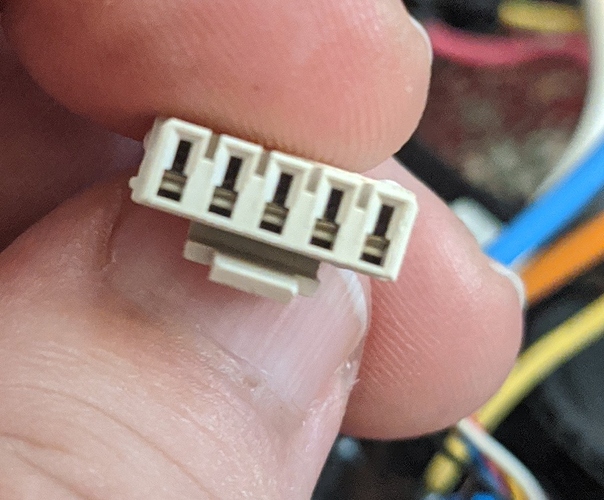

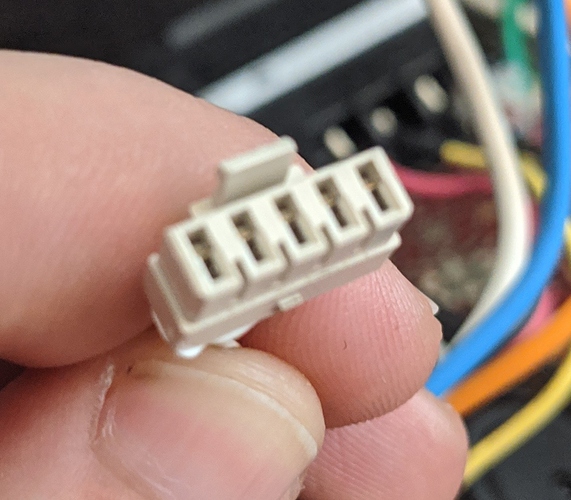

On a side note, I could really use some assistance identifying the stupid connector that Makita is using for the hall sensor.

EDIT :

Apparently new users cannot upload photos so if one of the other owners of this router could post a picture of the connector I would greatly appreciate it.

I’ve upgraded your account to help make up for the inconvenience — post away!

@WillAdams Excellent! Thank you for the upgrade.

@LiamN Thank you for posting those pics for me.

Found the connector:

http://www.jam-net.co.jp/eng/product/connector/post1376/

Specifically need the female rm25-05m and female rm25-04m. Unfortunately I cannot find them from a distributor.