Can someone please fill in the blanks on the fields in the custom tool library. Some things are self explanatory and others not so much.

Number=Tool number in library, arbitrary number assigned by user

Vendor=Who made tool

Model=Model Number of bit

URL=Vendor URL for model of bit

Name=Human Readable Name

Type=End,Ball,Vee,Engraver any others?

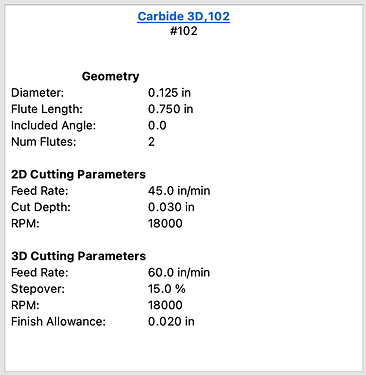

Diameter=Diameter of bit How to differentiate between imperial and metric

Cornerradius=

Flutelength=

Shaftdiameter=Diameter of bit shaft i.e 1/4/1/8, 4MM,8MM

Angle=

Numflutes=Number of Flutes on bit

Stickout=

Coating=

Metric=

Notes=

Machine=

Material=I assume these are the currated materials from Carbide3d Tool Databases

Plungerate=Rate which CNC will plunge bit Is this expressed in Imperial or Metric?

Feedrate=InchPerMinute (IPM) Rate which CNC will move bit Is this expressed in Imperial or Metric?

RPM=Revolutions per minute of router

Depth=Depth of Cut (DOC) per pass Is this expressed in Imperial or Metric?

Cutpower=

Finishallowance=

3dstepover=

3dfeedrate=

3drpm=