I haven’t seen it suggested…but what if you tack on the cost for pro when a new machine is sold? (not adding a licenses, just increasing the cost of the machine itself to cover development costs of the software). You’d have to do some internal accounting to see what the cost increase per machine would be. But, this would A) give current users zero issues with cost (almost like when you back a kickstarter early), and B) new users would essentially be agreeing to the cost increase when they make the choice to buy the machine. (*this could be an issue if you want CC to be used outside of the Carbide 3d family and collect the revenue from just software…as anyone could download it for free…perhaps just give a license to verified owners?)

Just a though.

We’re working hard to keep the machines as affordable as possible (without shifting production to China) and this should be a way to create a more premium version of the software and the cost will only burden those who choose to buy it.

Also, the support could actually cost more than the development over time so that’s an additional factor that we need to consider.

Well for the 4th time on this site and in an e-mail to Support that I sent about a month ago and I have still received NO reply except from the acknowledgement, the 400 series DOES NOT LOAD on my Mac since the last O/S upgrade. While I understand that it is not a supported product yet, it would be nice to get an acknowledgement that it is being looked at and if there is hope that 404 will work or even to tell me that you can’t replicate the issue and ask me some questions. BTW, it is not the first issue I report to support and get no acknowledgement even after I sent follow-up e-mail.

This isn’t really anything that would be specific to Carbide Create Pro, but since a few posts in this thread brought it back to mind…

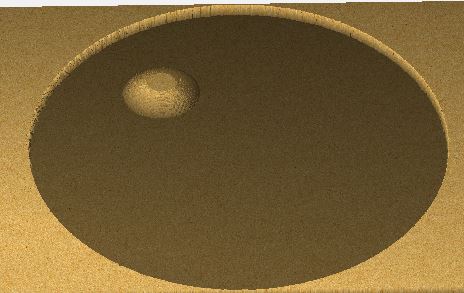

In the simulation in the current Carbide Create, there are a few texture options. I would really, really like to have a flat color option (just a standard midtone grey would be fine) so that the details in the model aren’t obscured by the texture image. Actually, that’s not entirely true. I should have used at least one more “really”: I would really, really, really like to have a flat color option.

Hmm… if you wanted to add a little lagniappe to sweeten Pro, letting the user apply a user-selected texture image would be fun. There, I’ve made it relevant to this thread!

So far all of the 400 releases of CC run on the Mac’s we have in the office, and CC is primarily developed on OSX. I’m not in the office now but I’m fairly sure they’re on the latest release of OSX.

OSX is actually very good about generating crash reports that help us track down bugs but you seem to have it hanging up, which won’t create a crash report. At this point we’re looking for repeated cases of the problem to try and correlate what might be going on.

That’s a good idea, we should do that. It’s on the TODO list now.

We found a couple of extra improvements to make in the vcarve calculation today. It’s not night and day but it does calculate a vcarve (based on the wonky c2d file).

We also added another optimization for the CTRL-A select all on big files to make it react faster.

Finally, we changed the vcarve linking based on your file. I don’t think it’ll machine any faster but I think most people will think it’s being machined faster because it’s a (seemingly) more logical path being taken.

CC appears on the bar and bounces. I have to force quit because it is not responding. I do have a report but no-one asked for it. Where should I send it?

I’ll ping you on the old ticket. You can reply to that.

EDIT: Got it!

I’ve got an easy one (well I think):

When importing a DXF file into CC which has spline elements, CC breaks each spline into 100 line segments. The parts I mill often have long splines that may measure as much as 10"-15", so the line segments created by CC become significant, especially around tight bends. The finished edge will appear to be faceted rather than a smooth curve as intended.

My solution has been to break up a single spline in multiple splines that are connected end to end. CC still converts each spline into 100 line segments, however now the individual line segments are shorter in length and thus the faceting is less noticeable.

Occasionally, when I’m exporting the design from my CAD system, I forget to break up the splines. I then import the DXF file into CC, create the toopaths, mill a part, and then afterwards realize that the faceting is apparent. This means that I have to go back and modify my original CAD data, import it into CC, reassign the toolpaths, and remake the part.

It would be nice if CC could recognize a spline as a smooth curve. If its necessary for CC to convert a spline into line segments, then it would be better if the length of each line segment was determined by a maximum length, rather than being 1/100th of the overall spline length. An even better solution would be if the segment length were to be determined by a maximum chord height value (similar to the way that a 3D CAD systems vary the size of triangles when you export an STL file).

Just want to again thank @robgrz for taking the time to do all this research and not only listen but put many of the requests into play immediately. Totally a class company and even if the machine and I don’t always get along (lol) I’m proud to be associated with and support you guys. I recommend you guys to a lot of people just for the customer service alone. Now off to get me some 4.04.

We have a new DXF parser that seems to be more relaible/generally compatible with a wide variety of DXF files. We hope to get it added in the near future and that should make it easier to fix this. The current DXF parser is “minimally acceptable” so we’re not putting anymore work into it at this point.

That’s how the output in CC works, but if the data comes in from the DXF parser at a reduced quality then there’s no way to fix it at that point. We’ll get better DXF parsing in the near future.

We appreciate the time that everyone has taken to give feedback here. I think 404 will be much better based on what everyone had to say on this thread.

UPDATE: We merged the new DXF parser into 404 today. Seems to better on the test files than the old one. There’s still work to do but it’s an improvement today. I think that’s about the final update for 404. We’ll hope to push everything to Unstable on Monday.

Just posted 404 to:

https://carbide3d.com/carbidecreate/unstable/

@edwardrford should have some Pro videos to share next week but you can try it out now if you’d like. Again, thanks for all the suggestions and help.

[EDIT] And just like that, 405 is now up.

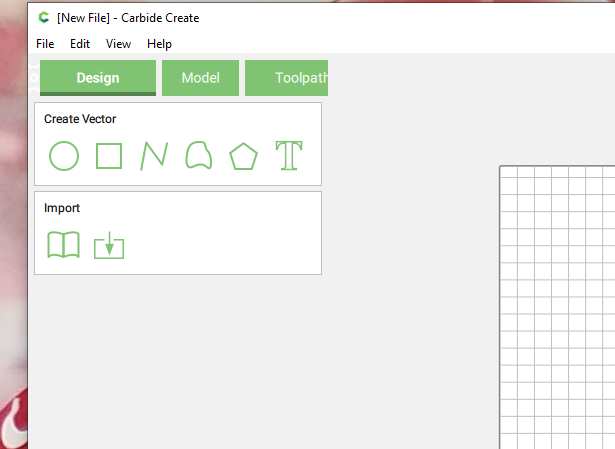

For folks who are confused as I was:

Help->About->Enable Pro. Then restart.

to get the “Model” tab.

And now 406 is up at https://carbide3d.com/carbidecreate/unstable/

Unless I’m missing something, 4.06 is missing the settings tab. Looks like the cog wheel icon is back there, just ever-so-visiable.

NEVERMIND: Just closed out and re-opened and it’s there. Strange.

When you enable or disable Pro, restart the app. There’s a layout problem we haven’t figured out yet.

when you have a 2d design and do a 3d model to it…i wanted to scrap it all, so i did file, new…it removed everything 2d but carried the 3d model over to the ‘new’ file. bug or user error?

No subscription for me either…and please keep it offline also because I work away from home and have time to design things while I am away and I don’t have internet in abundance where I work so it is cell data for me and would rather keep it offline as with carbide create is… thanks and am waiting for the pro version

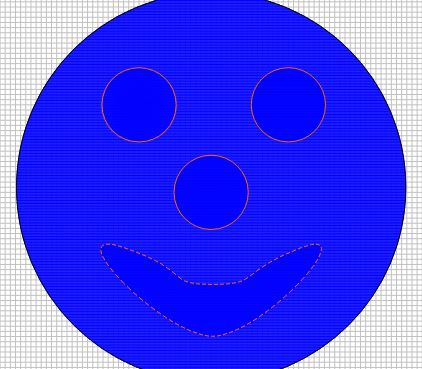

sorry if this isn’t as clear as it should be but, noticed a weird thing using unstable using 406. so created a quick smiley face, i made the first eye (just a circle) then made the tool path, just for the first eye only. everything good so far, go back to design and add the 2nd eye and nose using copy tool. try to add that to the first eye tool path made, and try to add the eye and nose an d mouth to that path and they don’t appear. haven’t tried to see if they cut or not

I would like to see project settings be adjustable and saved to a new default. Auto retract height, grid settings and stock thickness. Speeds and feeds need to be done in the same manner. Allow for bits to be customized and default settings changed. Auto fit to page would be nice when working with cutting many pieces out of same stock. It would also be nice if the file format could be changed so, that they could be shared easier without special programs and reformatting. When adding a node, make sure all editing functions are allowed. For example, add a node in to a line and you can not add a curves or can only add part of a curve. Very frustrating when trying to really dial your projects in!

Thanks,

Shawn

It would be most useful to add a “Notes” capability to the C2d design tab.

Here you could write construction notes, reminders and so on. Really useful when sharing c2d files with others (e.g on Cutrocket) or just reminding you how to set up and re-cut a new spoilboard or whatever.

Even better would be to add the stock size and tools used to the Notes at the click of a button - save having to open every toolpath individually to remind oneself of what is needed - or needs changing.