When trying to create a tool path. The tool path shows up as calculating. It stays this way for until I delete the path.

What is the relationship between the size of the endmill and the toolpath?

For a pocket the endmill should be smaller than the narrowest point of the geometry — if that’s not it, post the file and let us know what sort of endmill you wish to use, and what sort of toolpath you’re trying to apply.

Either way, IMO the process should not just hang there but it should do something to inform the user such as return a message that the toolpath is impossible to complete.

Currently I can’t reproduce the calculating problem. But I do have another problem with to .c2d files that I created while trying to make my project.

Atrached are two files that when opened by carbide create seem to show a blank project. They were both created from the same .svg file and then saved.My Clamp1.c2d (75.0 KB)

SingleClamp.c2d (841 Bytes)

EDIT: I thought the problem might be that I was using two different versions of carbide create. I’ve been using 316 and 413. After installing 416 the singleclamp file seems to work. At least I see the image on the screen.

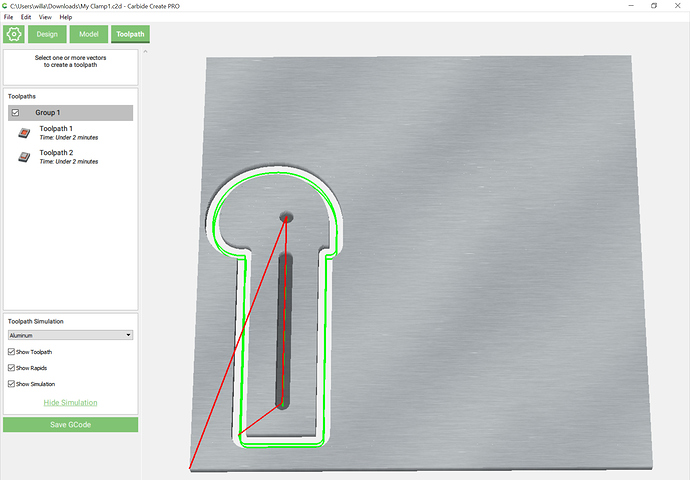

My Clamp1.c2d seems to be fine in CC431:

SingleClamp.c2d is only 841 bytes and is empty save for the base template of the file.

If that build doesn’t work for you, let us know at support @carbide3d.com and we’ll do our best to help you puzzle things out.

Thanks. I thought I checked the size of the file. I think I dropped down a line when I checked the size.

I think I also found the problem with my depth of cut problem. I have made several copies of this clamp.

The last one again cut to deep on the first pass. So I checked the Z movement and it was moving .202 inches. So I checked all of the values for the cut and everything said is should cut .111 on the first cut. What I found was that the material was set to wax. I think this is what happened the last time.

I’ve been looking into the feed/speed information that you have posted. The values for pine are different than the values in carbide create for soft wood. The same for MDF. Carbide uses .111 for DOC the posted charts show .4 and .3 for DOC.

One of the reasons that I was looking into this is that I was trying to make a knob similar to a star knob. It was .750 stock and about 1.250 in diameter. The time to run was close to an hour.

Here is my knob.c2d file it is showing the calculating issue. Not sure of the proper procedure to create the toolpaths. Half of the knob is a pocket around the square in the middle. If you cut the pocket first then the perimeter path is still .750 while the pocket is .375 deep. So I thought that I should cut half of the outside perimeter then cut the pocket then finish with the perimeter cut for the other .375.

But then I thought that maybe I should combine the pocket and perimeter into a single pocket of .375. Then finish the perimeter.Knob.c2d (277.8 KB)

Sorry for the rambling.

Thanks for your help.

PS I changed to toolpaths and have it own to about 6 minutes.

The router speed setting should match the feeds and speeds for your selection of endmill and material. Please see:

(there’s a row matching dial settings to RPMs at the bottom)

There’s an interactive version at: https://public.tableau.com/profile/willadams#!/vizhome/Carbide3DCNCFeedsandSpeeds/Sheet1?publish=yes

See https://www.youtube.com/watch?v=S9bceJxpqG0 for concepts on this and see the series #MaterialMonday: #MaterialMonday on YouTube for specifics.

You should test feeds and speeds in a piece of scrap using the technique at: https://precisebits.com/tutorials/calibrating_feeds_n_speeds.htm

Another consideration is Climb vs. Conventional Milling and tooling engagement — where possible avoid slotting and add geometry and cut as a pocket (Adding geometry to cut as a pocket with a finishing pass ).

Thanks for the fast response. I will check into these.

Being new to CNC routing. Once one has determined the feed and speed rate. Where does one enter these values? The bits in the library can’t be modified.

Click on “Edit” under the tool, then clear the checkbox for “Set speeds automatically” — then one can edit the feeds and speeds for each toolpath.

Thanks. That was very helpful.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.